-

-

-

-

-

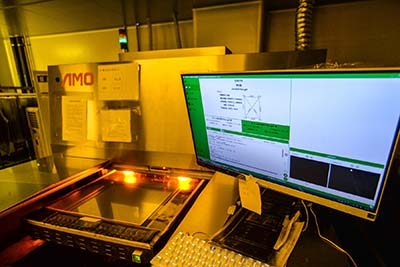

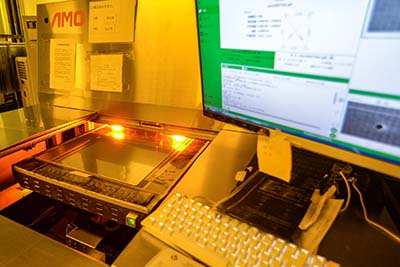

Light painting operation--photographing system

The process is as shown below: (PCB/LCD design)-->(CAM system)-->(Gerber file)

3541 1 0 Shares

-

-

-

-

-

-

-

PCB Design Principles

Eight Principles of PCB Design

3978 1 0 Shares

-

-

PCB design skills based on GENESIS2000 software (2)

Part 6-12

5273 5 0 Shares

-

PCB design skills based on GENESIS2000 software (1)

Part 1-5

4207 1 0 Shares

-

-

-

-

-

Categories

Recommended Article:

- Exploring the Significance of Drill Holes in PCB Manufacturing

- From Prototype to Mass Production: The Role of Golden Boards in PCB Industry

- Unveiling the Characteristics and Implementation of Flip Chip Bonding Technology

- DFRobot x NextPCB LattePanda MU Carrier Board Design Challenge - NextPCB Accelerator #9

- Unlock Open-Source FPGA Innovation with Tang Primer 25K from Sipeed - NextPCB Accelerator #8

- Top 9 Most Common IC Packaging Types in Modern Electronics

- Harnessing the SIM7600's Full Potential: A Systems-Level Perspective

- Comprehensive Comparison of PCB Additive and Subtractive Methods

- Deploy Smarter IoT solutions with SIM7600 4G LTE Modules and Free Prototypes - NextPCB Accelerator #7

- Understanding the Differences Between CPU, MCU, MPU, SoC, DSP, ECU, GPU, and FPGA