Prepregs, cores, foils

Posted:09:33 AM December 31, 2019

writer: NextPCB

What is prepreg?

Prepreg is an insulation layer between two cores or between a core and copper foil. Prepregs are also called as "PP sheets", which are the primary materials in multilayer PCB production. Most of the prepregs used in PCBs are fiberglass impregnated with resin (an epoxy-based material). And there are different types of prepregs according to the thickness and other requirements, such as a standard resin(SR), medium resin (MR), and high resin(HR) depending on the amount of resin they hold. The more resin they contain, the higher their price.

How does the prepreg work?

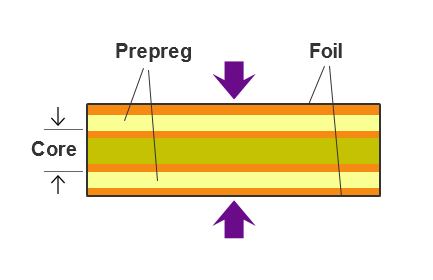

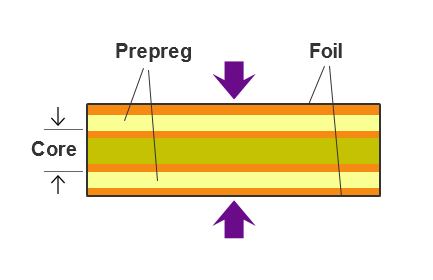

The prepreg is the insulating layer in multilayer PCBs, which plays a role that holds all the layers together in the fabrication process. The prepreg is dry but not hard before using, which allows itself to flow through the PCB when heated. Then the fiberglass is impregnated with resin before being dipped into the layer. Once aligned, the plug is heated and pressure is applied to soften the material. The PCB will cool and begin to solidify after all is completed, all the layers are get together and created to the desired board thickness at last.

The layers of prepreg exist each layer of the PCB, and it likes an adhesion to stick the etched cores together or glue the copper foil to the etched core. When the prepreg is used in the multilayer PCB, the surface should be smooth, with no oil, no defects, no stains, no cracks, and no excessive resin powder.

What is the core?

The prepregs and the cores are often mixed. In fact, they are two separate parts of the board. The core is the dielectric substrate layer with copper traces above and below in a PCB. The substrate layer usually can be FR4, Polyester, Polyimide, PTFE, CEM-1, CEM-3, and metalcore (i.e., aluminum base or copper base). The aluminum core is widely used in electronic products that need excellent heat transfer and heat dispassion capabilities. NEXTPCB can provide the aluminum core for PCB manufacturing.

What is the copper foil?

The copper foil is the base copper thickness applied to the inner and outer layers. After heating, the prepregs, the cores, and the copper foils are pressed together to form a PCB. The copper foil can be pre-attached to the base material core by the laminate manufacturers, or it can be introduced into the multilayer board as a copper foil before pressing.

Thin copper foil is produced by electroplating or rolling. There is a copper foil of 1oz (35 μm) and 2oz (70 μm) available in NextPCB.

There are various types of materials of the board in NextPCB for customers' choice, please fill in the proper requirements in the online quote sheet, or you can contact online services for further help if you have any problems in PCB manufacturing and assembly.

PCB Assembly

PCB Assembly

Layer Buildup

Layer Buildup

Online Tools

Online Tools

PCB Design-Aid & Layout

PCB Design-Aid & Layout

Mechanics

Mechanics

SMD-Stencils

SMD-Stencils

Quality

Quality

Drills & Throughplating

Drills & Throughplating

Factory & Certificate

Factory & Certificate

PCB Assembly Factory Show

Certificate

PCB Assembly Factory Show

Certificate