Support Team

Feedback:

support@nextpcb.comIntroduction

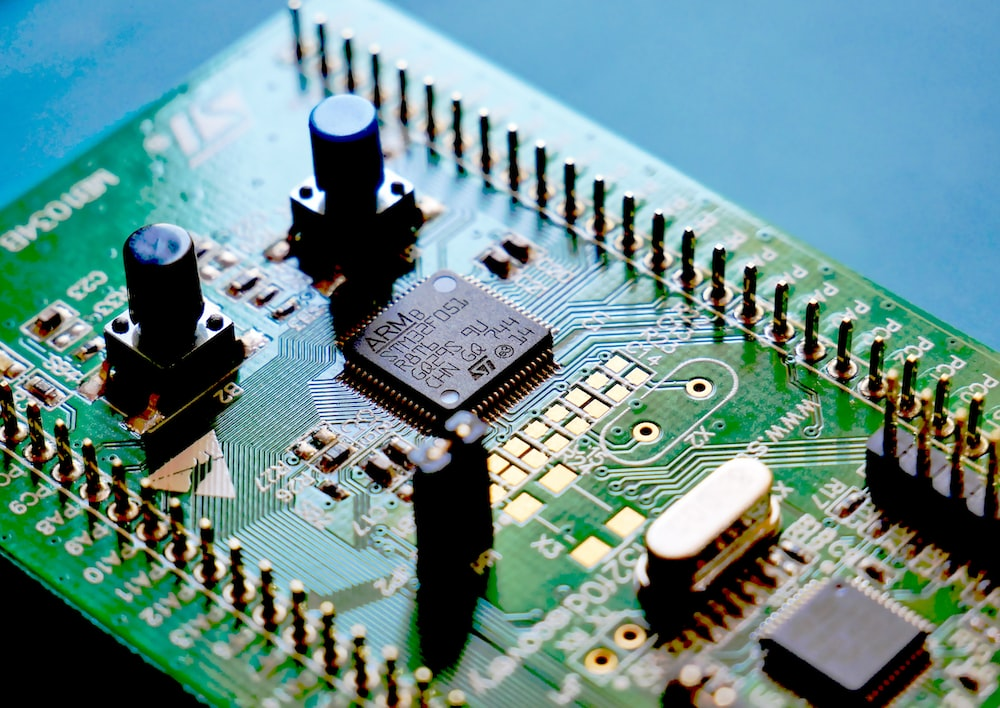

Printed Circuit boards (PCBs) are the unseen backbone of modern electronics, yet their production costs can span a monumental range—from as little as 50 cents for a simple module to over $500 for high-complexity, multi-layered assemblies. This vast difference highlights a critical reality for designers and engineers: PCB manufacturing is not a fixed-price commodity.

Manufacturers meticulously assess a complex set of criteria before quoting a final price. These considerations, ranging from fundamental material choices to intricate production timelines, directly determine whether your project falls on the lower or upper end of the cost spectrum.

If you are currently navigating the market to design and procure a Printed Circuit Board, understanding these variables is essential. This guide serves as your comprehensive tool, breaking down the key factors that can either dramatically inflate or successfully reduce your Printed Circuit Board Costs, ensuring you achieve optimal performance without breaking your budget.

> To explore the full details and learn how to optimize your budget, please visit:, please visit: PCB Cost Analysis: Key Factors and Cost Reduction Strategies

| Category | Key Cost Factor | Brief Explanation |

| Structure & Materials | PCB Material | Material type (Rigid/Flex), size, and required performance (e.g., high-frequency, thermal properties). |

| Layer Amount | More layers mean more fabrication steps and materials, increasing the cost. | |

| Board Size | Larger dimensions require more material and panel space, leading to higher costs; component density also plays a role. | |

| Manufacturing & Components | Electronic Components | Higher component count, complexity, and scarcity of parts increase costs. |

| Via Type | Complex vias (e.g., blind and buried vias) add complexity and cost to fabrication. | |

| Manufacturing Process | Additional processes like silkscreen, relays, or complex stencils add to the total expense. | |

| Production & Order | Order Quantity | Higher volumes generally result in a lower unit cost. |

| Turnaround Time (TAT) | Shorter production times (rushed orders) significantly increase costs. | |

| Testing Requirements | More extensive testing (e.g., ICT) increases manufacturing costs. | |

| Labor Cost | High-skill labor and complex designs increase the overall labor and overhead cost. |

Flexible PCBs' raw materials are polyester film or polyester amide; Their characteristics include thin, high assembly density, higher flexibility, and bendable and foldable, which are uncommon in rigid Printed Circuit Boards.

They can withstand multiple twists, bends, and folds while retaining their operations, offering good heat dissipation functionality. Many factors influence flexible PCB costs.

Other Factors include panel utilization, size and volume of flexible PCBs, differences in geographic regions, and surface finishes that influence the price of flexible PCBs.

Rigid-flex PCBs are hybrid boards consisting of internal flex and external rigid layers. Rigid-flex PCBs are approximately seven times more expensive than traditional rigid PCBs. The price range This price results from the kind of raw materials required.

Even though Rigid-Flex PCBs use materials common to rigid and flexible PCBs, such as core laminate, copper foil, laminates (flexible), prepreg, bond plies, and cover layers, there are distinct differences in the design process.

The no-flow prepregs are a vital component to designing a Rigid-Flex PCB successfully. No flow prepregs generally cost more than traditional FR4 and polyimide prepregs (up to ten times more expensive).

No-flow prepregs come in two variants (106 and 1080) and are thin glass fabrics. This limitation makes it difficult for Rigid-flex PCB manufacturers to use lower costs and thicker fabrics than traditional rigid PCB utilities.

In addition, Rigid-flex PCBs separate individual components before the final assembling of the parts into the last board. This process further increases the design process and circuit complexity, thereby increasing cost.

The manufacturing yield of Rigid-flex PCBs adds to the overall costs. Combining dissimilar materials with different stability characteristics requires expertise, specialized machines, and software tools. As a result, the yield in rigid-flex manufacturing is reduced than in traditional rigid or flexible circuits.

As a manufacturer, reducing PCB costs on Printed Circuit boards while retaining optimum performance is essential. As consumers, it is necessary to consider factors that can minimize final PCB costs to avoid breaking the bank.

The average price of a Printed Circuit Board ranges from $0.02 to $0.05 per square inch. There are dozens of factors that could affect the cost of a Printed Circuit Board. All these factors have a linear relationship with PCB costs.

The cost per square Inch of a PCB varies directly with the board size, volume, number of layers, and board complexity. Also, the number of electric components must be reduced on the circuit board to minimize PCB costs.

The cost of Wholesale PCBs ranges from $1 to $500. While these costs vary from manufacturer to manufacturer, wholesale PCB costs are relatively cheaper. However, purchasing Printed Circuit Boards at wholesale price is beneficial if you plan to buy a significant number of PCBs.

Printed Circuit Boards are the core of electronics. Despite their complexities and design, knowing how much they cost is imperative. This guide has provided factors to consider when you want to purchase or manufacture a Printed Circuit Board.

It is essential to consider these factors as you can streamline your PCB designs according to your budget. Also, the various types of PCBs and costs were thoroughly explained in this guide for consumers who wish to know the kinds of PCBs available in the market.

Are you looking for a specific kind of PCB? Or are there factors you wish to determine if they influence PCB costs? Kindly contact us via email or support, and we will gladly give you an expert-led answer.

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now