Support Team

Feedback:

support@nextpcb.comIn the PCB (Printed Circuit Board) industry, a Golden Board (or reference standard board) is a critical concept representing a rigorously validated, defect-free PCB board that serves as a benchmark for PCB design, PCB manufacturing, and quality control. Below is a comprehensive breakdown of its definition, roles, production process, applications, and distinctions from regular PCBs:

A Golden Board serves as a benchmark template in the PCB design and manufacturing process, characterized by the following features:

In the PCB industry, Golden Board and First Article Inspection (FAI) are critical quality control concepts, but they differ significantly in terms of application scenarios, functional goals, and execution methods.

| Dimension | Golden Board | First Article Inspection (FAI) |

| Definition | Refers to a fully verified perfect sample used as a benchmark for production, testing, or design. | Refers to the full-dimensional inspection of the first completed product (or first batch of samples) before mass production. |

| Function | Calibrates equipment parameters, verifies testing procedures, defines acceptance criteria, or serves as a basis for quality agreements between customers and suppliers. | Verifies production processes, material compatibility, and design feasibility to ensure consistency in subsequent production. |

| Application Phase | After design finalization, used as a long-term reference standard. | Performed every time production is initiated or when process changes occur. |

| Verification Goal | Establishes design or testing benchmarks. | Verifies the compliance of the current production process. |

| Update Frequency | Updated only when design changes or standards are iterated. | Performed before every production batch. |

| Responsible Party | Usually provided by the designer or customer. | Executed by the manufacturer and inspection reports are submitted. |

| Inspection Scope | Focuses on overall performance and long-term stability. | Covers the comprehensiveness of processes, materials, and equipment parameters. |

| Example | In SMT (Surface-Mount Technology) assembly, the Golden Board may include standard solder pad shapes and component layouts, used to calibrate parameters for AOI (Automated Optical Inspection) equipment. | In PCBA (Printed Circuit Board Assembly) processing, the FAI requires passing visual inspection, functional testing, and environmental adaptability verification. |

In practical application, the Golden Board serves as a reference for the First Article Inspection (FAI), where it is used as a benchmark to assess whether the first article meets predefined quality standards. Conversely, the FAI validates the feasibility of the Golden Board when it is first put into production, ensuring its suitability in the actual manufacturing environment.

● Before PCB mass production, the Golden Board is used to validate design feasibility, including signal integrity (SI), power integrity (PI), thermal management, and mechanical structure.

● Testing identifies potential issues (e.g., impedance mismatch, electromagnetic interference), guiding design optimization.

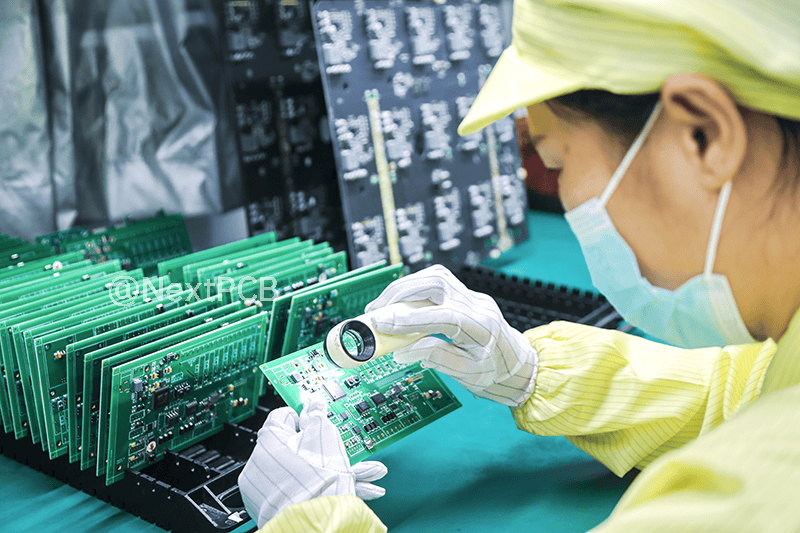

● During PCB Mass production, the Golden Board serves as the "gold standard" for quality comparison, ensuring each batch of PCBs matches its performance, dimensions, materials, etc.

● Helps pcb factories quickly detect manufacturing deviations (e.g., trace width errors, layer misalignment, soldering defects).

● Calibrates testing equipment (e.g., flying probe testers, AOI systems) to ensure measurement accuracy.

● In functional testing, the Golden Board acts as a "known good board" to validate the effectiveness of testing procedures.

● When faults occur during mass production, comparative analysis with the Golden Board allows for rapid pinpointing of the root cause (design defect vs. process defect).

● High-Precision Design: Layout and routing are completed using professional EDA tools (e.g., Altium, Cadence) to ensure compliance with electrical and mechanical specifications.

● Simulation Verification: Signal integrity, thermal, and EMI simulations to predict performance.

● Strict adherence to substrate materials (e.g., FR-4, Rogers HF materials), copper thickness, and surface finishes (e.g., ENIG, OSP).

● Produced by experienced engineers in a controlled environment to avoid fluctuations from mass production equipment. High-precision equipment (e.g., laser drilling, LDI exposure machines) is used to ensure process consistency.

● Electrical Testing: Includes impedance testing, continuity testing (flying probe testing), and insulation resistance testing.

● Functional Testing: Actual power-on operation to verify signal transmission, power consumption, heat generation, etc.

● Reliability Testing: Accelerated aging experiments such as high-temperature and high-humidity tests, thermal cycling tests, and vibration tests.

● Jointly confirmed and signed by clients, design teams, and quality departments, archived as a legal reference for mass production.

| Aspect | Golden Board | Mass-Produced PCBs |

| Purpose | Design validation, benchmarking | Volume production, end-use |

| Production | Low-volume, precision-controlled | High-volume, process variations |

| Testing | Full validation (electrical + functional + reliability) | Sampling (e.g., AOI, flying probe) |

| Cost | High (iterations, exhaustive tests) | Low (economies of scale) |

● Risk Control: Prevents production failures due to design defects, reducing economic losses.

● Efficiency Improvement: Shortens product development cycles through standardized processes.

● Quality Consistency: Ensures stable performance of mass-produced products, meeting industry standards (e.g., IPC-A-600).

The Golden Board serves as a vital bridges between PCB design, PCB manufacturing, and quality control in the PCB industry, making it indispensable, especially in high-end electronics sectors that demand high frequency, high density, and high reliability.

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now

|

Dimensions: (mm) |

|

|

Quantity: (pcs) |

|

|

Layers: 2 |

Thickness: 1.6 mm |

|

|

|