-

The golden rule that PCB design never changes

10 Rules

3402 1 0 Shares

-

PCB design technology

PCB design techniques have an impact on the following three effects:

3697 1 0 Shares

-

-

-

-

PCB layout design view elements

55 elements

3515 1 0 Shares

-

-

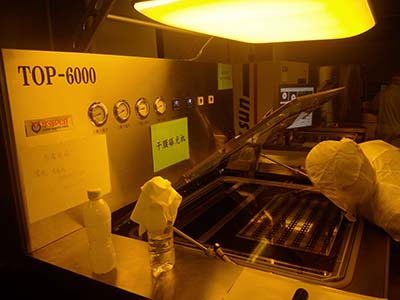

PCB basic manufacturing process

The PCB manufacturing process begins with a "substrate" made of Glass Epoxy or similar material.

3383 1 0 Shares

-

-

-

-

-

-

-

-

-

-

-

-

Categories

Recommended Article:

- DFRobot x NextPCB LattePanda MU Carrier Board Design Challenge - NextPCB Accelerator #9

- Unlock Open-Source FPGA Innovation with Tang Primer 25K from Sipeed - NextPCB Accelerator #8

- Top 9 Most Common IC Packaging Types in Modern Electronics

- Harnessing the SIM7600's Full Potential: A Systems-Level Perspective

- Comprehensive Comparison of PCB Additive and Subtractive Methods

- Deploy Smarter IoT solutions with SIM7600 4G LTE Modules and Free Prototypes - NextPCB Accelerator #7

- Understanding the Differences Between CPU, MCU, MPU, SoC, DSP, ECU, GPU, and FPGA

- RAK3172: The Ultimate LoRaWAN Module for IoT Applications in 2025

- Build Low-Cost FPGA Projects with Tang Nano 20K and Free PCBA Prototypes - NextPCB Accelerator #6

- NextPCB DFM Tool Exclusive Offer: Get a $10 Coupon Every Month!