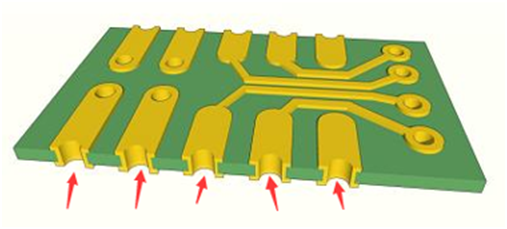

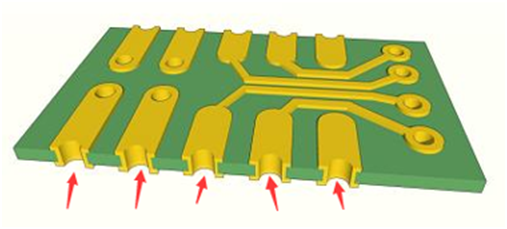

Plated Half-holes/Castellated Holes

Posted:07:52 PM December 26, 2019

writer: NextPCB

Plated half-holes also called castellated holes, which are the holes drilled and plated with copper using a specialized process alongside the boundaries of the boards. As the holes pass through the plating, the edges are truncated, so the holes along the border will be halved. The edges of the PCB look like the top of a plated half-hole PCB.

The applications of plated half-holes

Plated half-holes are mainly used for board-on-board connections, mainly combining two printed circuit boards with different technologies. By connecting directly to the PCB, the entire system is much thinner than comparable connections for multi-pin connectors. Plating edges can also be used to produce small PCB modules that are soldered onto a giant board similar to the way of mounting ICs. Please pay attention that the plated half-holes are not suitable for single-layer boards.

Other applications include displays, ceramic modules, or high-frequency, which are soldered to a basic board. PCB with plated half-holes is applied to industries in computers, telecommunication, power, automobile, industrial control, and high-end consumer electronics, etc.

The benefits of plated half-holes

1. The plated half-holes can be accurately milled to improve process reliability because the plating is protected from mechanical damage by providing a copper shell.

2. The plated half-holes offer an additional method of connecting circuit boards side-by-side with the PCB borders, which was left idle from the beginning.

3. The plated half-holes can convert the circuit boards into surface-mount sub-assembly. These boards provide a better landing for soldering when recessed and plated.

4. The position of plated half-holes on the board boundary indicates that the surface-mount components or daughterboard will be flush with the motherboard surface. Once the device is in place, there is no space for dust or moisture.

How to indicate the half-holes in the PCB design?

The half-holes design in PCB varies from different software, but the result in the Gerber file is similar. Add through-holes or plated holes directly to the outline of the PCB board that needs to be plated with half-holes. And make sure that half of the holes are on the board and half are outside the outline. The data of half-holes should include:

1. Copper layers (GTL and GBL): the copper pads on the top and bottom copper layers of each half-holes.

2. Solder mask layers (GTL and GBL): the solder mask openings on both sides.

3. Drill layer (TXT/DRL): the drill hole for each half-hole.

4. Mechanical/Outline layer (GML/GKO): the contour should pass through the drilled hole.

It sounds like half-holes in PCB manufacturing is a simple process flow for drilling, plating, and routing. In fact, it requires additional processes and careful production planning. Therefore, it is crucial to choose a professional PCB manufacturer for fine processes. Castellated holes are available on both standard PCB and advanced PCB in NextPCB. For the standard PCB services, the minimum diameter of the plated half-hole is 0.5mm, the minimum distance between two plated half-holes is 0.55mm. Please contact online services or send Emails to support@nextpcb.com if you need smaller plated half-holes. NextPCB will try our best to fabricate plated half-holes you need with high-quality. For any other requirements in the PCB assembly prototype or PCB mass production, please tell us directly.

PCB Assembly

PCB Assembly

Layer Buildup

Layer Buildup

Online Tools

Online Tools

PCB Design-Aid & Layout

PCB Design-Aid & Layout

Mechanics

Mechanics

SMD-Stencils

SMD-Stencils

Quality

Quality

Drills & Throughplating

Drills & Throughplating

Factory & Certificate

Factory & Certificate

PCB Assembly Factory Show

Certificate

PCB Assembly Factory Show

Certificate