NextPCB Quality Certifications and Test Reports

At NextPCB, we take product safety and manufacturing standards very seriously. That's why we have always made it our priority to maintain compliance with international industry standards, demonstrating our commitment to quality, environmental protection, and regulatory compliance.

Our manufacturing facilities are certified to IATF16949, ISO 13485, ISO 9001, and ISO 14001 standards for quality management, environmental management, and product safety. We also comply with UL, RoHS and REACH regulations to ensure our PCBs and production processes meet stringent international standards for materials restrictions, emissions, and more.

You can place your trust in NextPCB knowing that all products will be manufactured with the highest regard for people and the environment.

Our certifications and test reports are registered under our Chinese name, Shenzhen Huaqiu Electronics. Click here to download our latest certificates and test reports.

-

UL Underwriters Laboratories Certification

UL Underwriters Laboratories Certification

-

UL listing is important for products sold in North America and is recognized in other regions as well. Only products that demonstrate full compliance with applicable UL standards become UL Listed and can use the UL mark. The UL Mark has become a widely recognized symbol reassuring buyers that certified items adhere to critical safety guidelines.

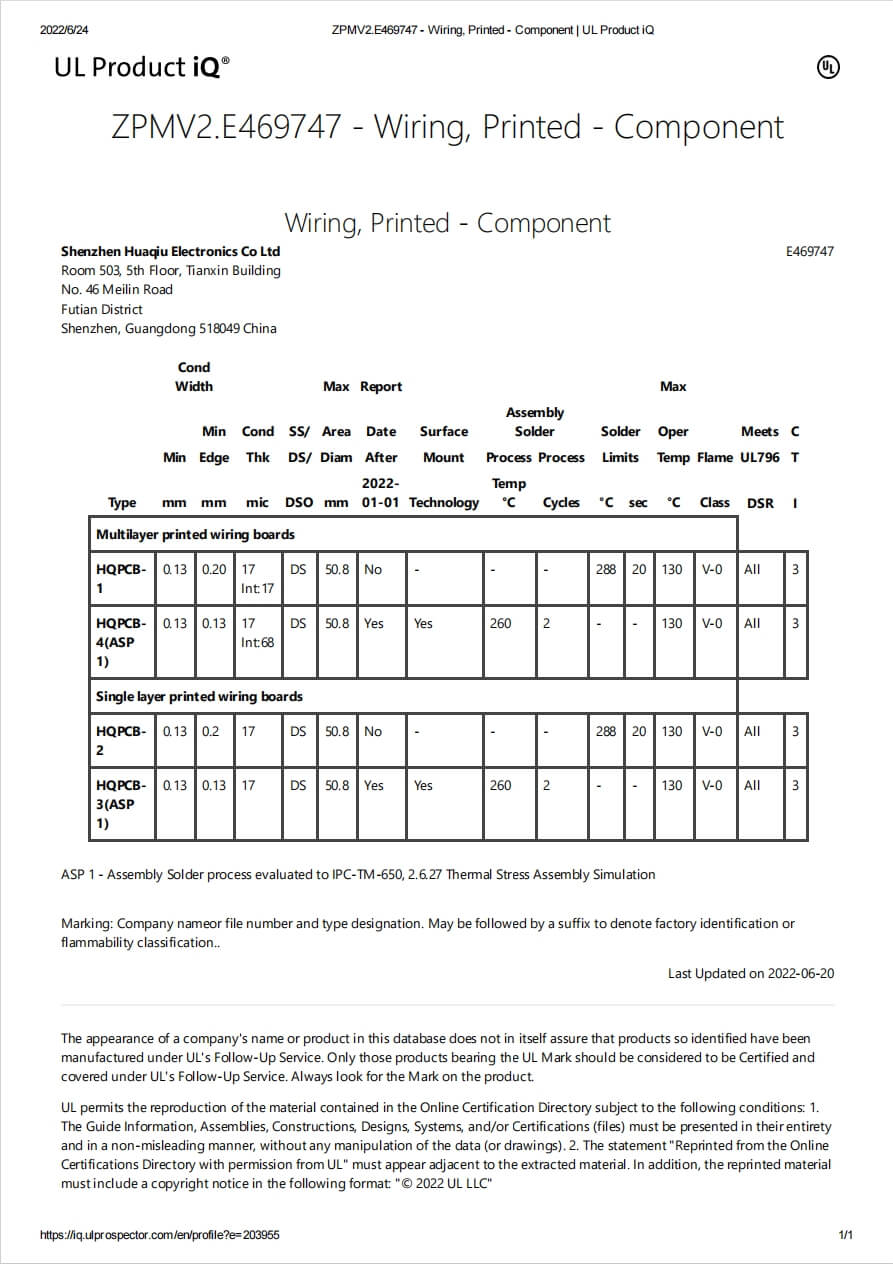

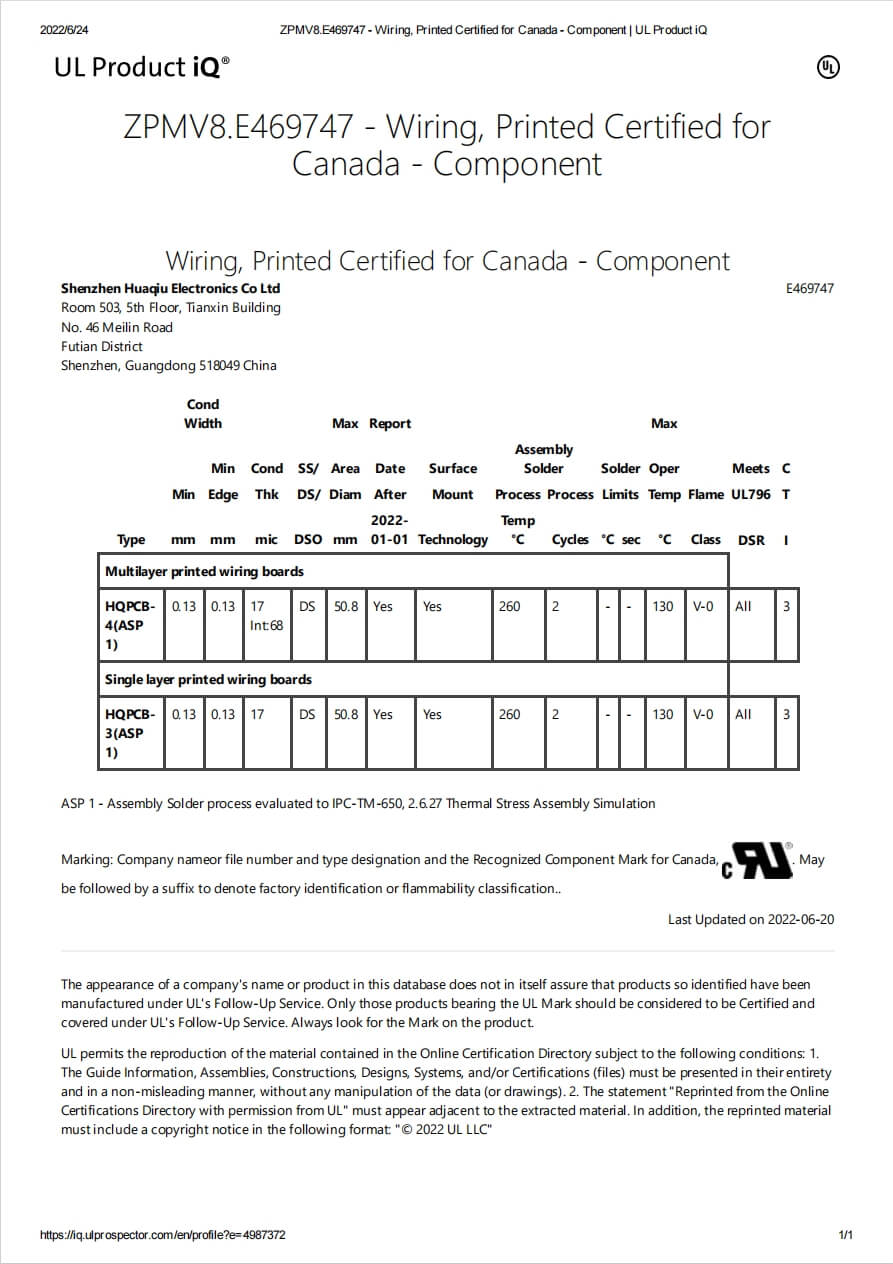

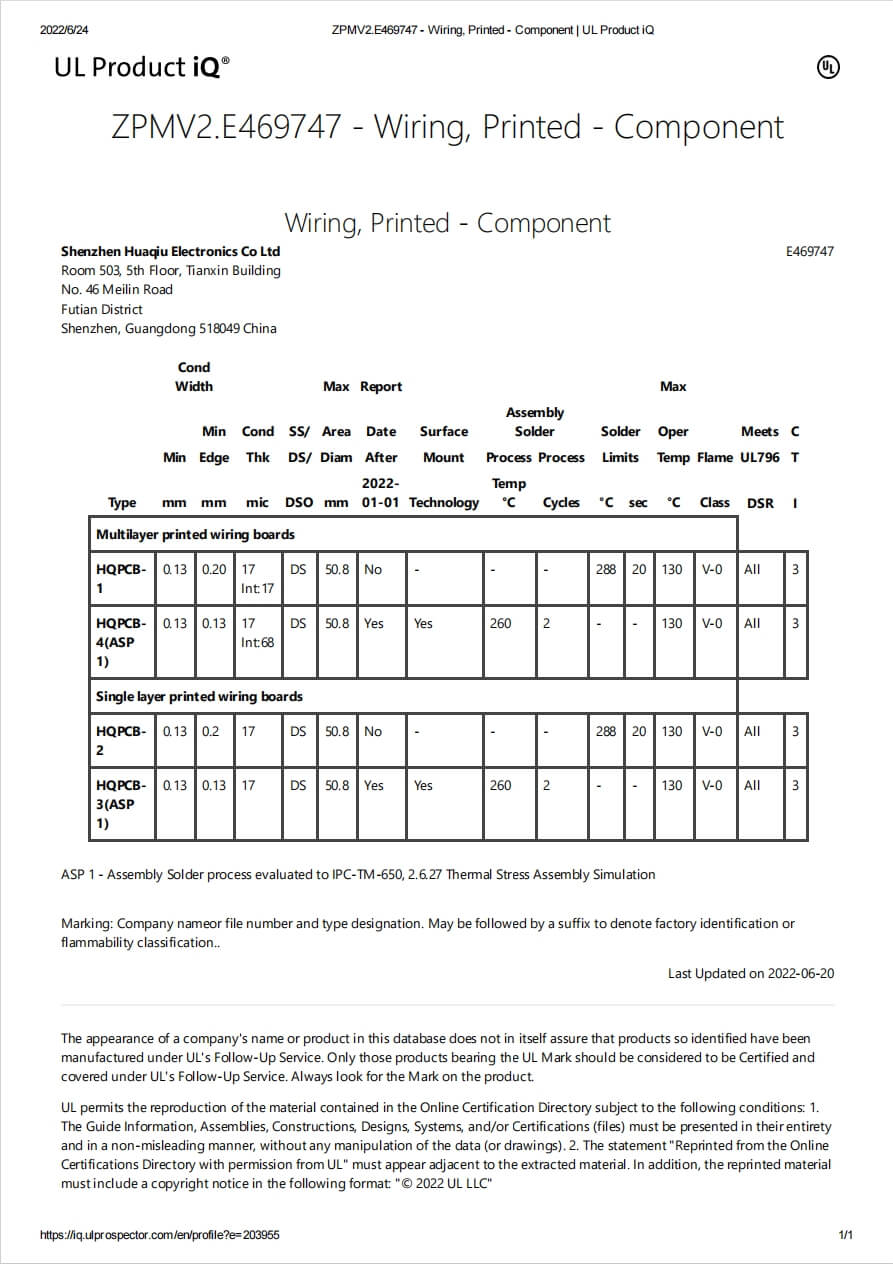

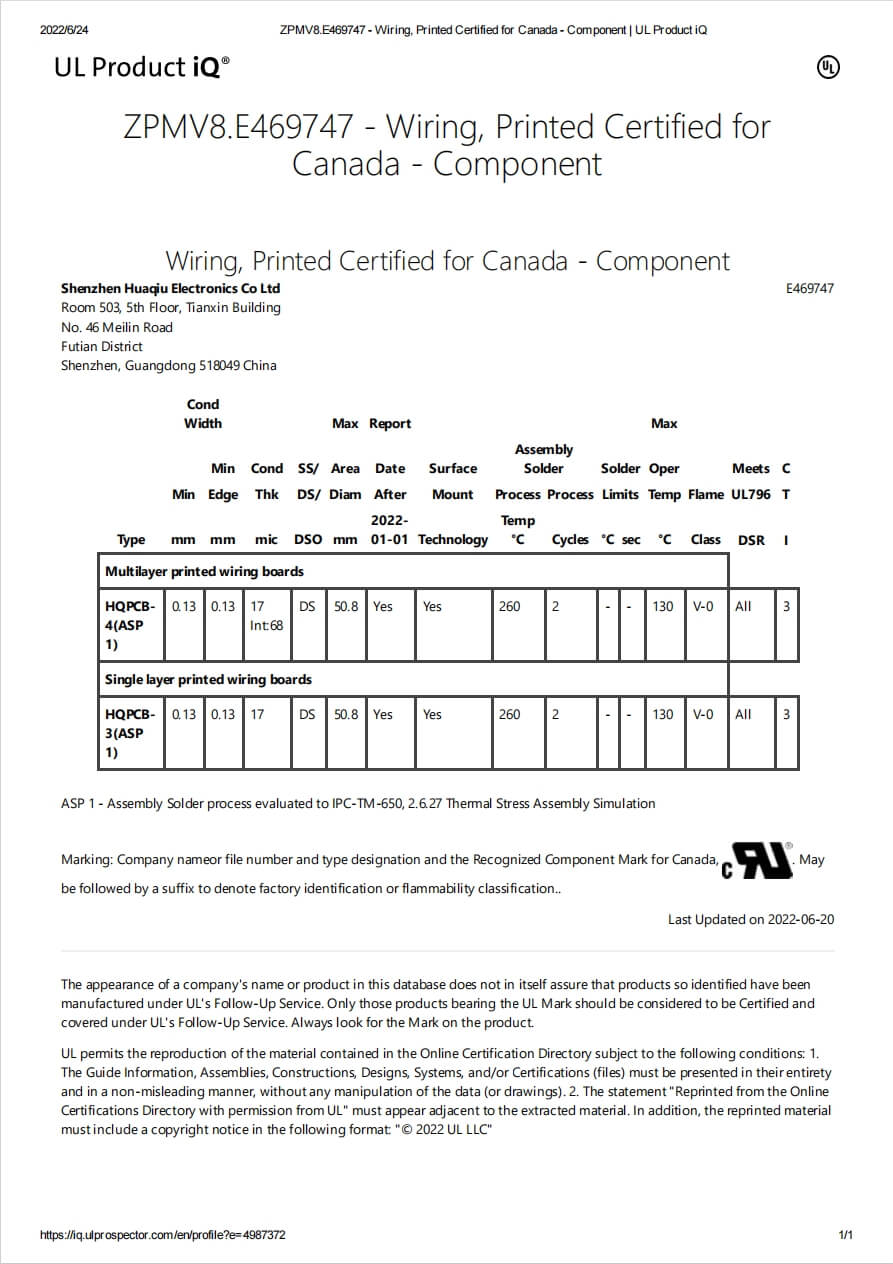

All printed circuit boards produced by NextPCB are fabricated using a UL 796 inspected process and these printed circuit boards can be used in UL-approved products. You can request the addition of our UL mark and number on your circuit boards directly on our order platform.

NextPCB’s UL identification number is E469747

|

|

| NextPCB UL Product iQ US Listing |

NextPCB UL Product iQ Canada Listing |

-

ISO 9001 Quality Management System Certification

ISO 9001 Quality Management System Certification

-

The ISO standards are International Quality Management systems developed by ISO (International Organization for Standardization).

ISO 9001 provides a framework for organizations to effectively manage their quality systems through documented processes and continuous improvement activities. As an ISO 9001 certified company, NextPCB’s processes have been verified by an authorized third party to meet ISO 9001 standards and demonstrate NextPCB’s commitment to quality and excellence.

|

|

|

| Jiujiang PCB Factory ISO9001:2015 Certificate |

Shenzhen PCBA Factory ISO9001:2015 Certificate |

Changsha PCBA Factory ISO9001:2015 Certificate |

-

ISO 14001 Environmental Management System (EMS) Certification

ISO 14001 Environmental Management System (EMS) Certification

-

ISO 14001 is designed to help organizations minimize the negative impact of their operations on the environment through compliance with regulations and continual performance improvement. This certification illustrates NextPCB’s dedication to environmental awareness, stewardship and sustainability and verifies that NextPCB has effective practices and policies in place to minimize their environmental impact.

|

|

|

| Jiujiang PCB Factory ISO14001:2015 Certificate |

Dongguan PCBA Factory ISO14001:2015 Certificate |

Changsha PCBA Factory ISO14001:2015 Certificate |

-

ISO 13485 Medical Devices Quality Management System Certification

ISO 13485 Medical Devices Quality Management System Certification

-

ISO 13485 is a quality management system standard for ensuring the quality and safety of devices used in medical applications. The standard puts a stronger emphasis on risk management and compliance with medical regulations such as FDA and EU MDD/MDR. NextPCB’s ISO13458 compliance demonstrates our commitment to patient safety and shows that our quality processes stand up to international medical standards.

ISO 13485 is a quality management system standard for the manufacture of medical devices, therefore, it only applies to our PCB assembly services.

|

|

| Dongguan PCBA Factory ISO13485:2016 Certificate |

Changsha PCBA Factory ISO13485:2016 Certificate |

-

IATF 16949 Automotive Directive

IATF 16949 Automotive Directive

-

A quality management system standard specific to the automotive industry, IATF 16949 was developed by the Automotive Industry Task Force for greater defect prevention, process control and product safety. IATF 16949 builds on ISO 9001 and also requires third-party auditing. NextPCB’s IATF 16949 certification illustrates their capability to meet the high expectations of automakers and their customers.

|

|

|

| Jiujiang PCB Factory IATF16949:2016 Certificate |

Dongguan PCBA Factory IATF16949:2016 Certificate |

Changsha PCBA Factory IATF16949:2016 Certificate |

-

RoHS Directive

RoHS Directive

-

The Restriction of Hazardous Substances directive is an environmental regulation that limits the use of certain hazardous materials in electronic devices including lead, mercury, cadmium PBBs and PBDEs. Products must be RoHS-compliant to be legally sold in the EU.

For PCB manufacture and assembly, lead content is of most concern and is commonly used in lead-based solders and surface finishes. However, NextPCB exclusively employs lead-free solder and solder pastes in their assembly facilities, and the RoHS compliance of the product depends on the RoHS compliance of the parts chosen by clients.

For PCB manufacture, NextPCB offers a variety of lead-free, RoHS compliant surface finish options including lead-free HASL, ENIG and OSP. Leaded HASL surface finish is available but should be reserved for devices not bound for EU markets, for example for prototyping purposes.

RoHS compliance can be declared via third-party testing of the end product, or by tracing compliance of the materials used to make the product.

Below are the RoHS test reports for circuit boards with lead-free HASL, ENIG and OSP surface finishes. Also included are the manufacturer RoHS reports for the solder mask oils used in production.

|

|

|

| NextPCB Lead-free HASL RoHS Test Report |

NextPCB ENIG RoHS Test Report |

NextPCB OSP RoHS Test Report |

-

REACH

REACH

-

REACH stands for Regulation for Registration, Evaluation, Authorization and Restriction of Chemicals and is the main legislative instrument regulating chemicals in the EU. Within it are 241 Substances of Very High Concern (SVHC) as of July 2022, which include lead and lead compounds and flame retardants such as HBCDD and TBBP-A that may be used in some PCB laminates.

As with RoHS, NextPCB can assure its clients that no SVHCs are present above the acceptable limits stipulated by REACH in their lead-free PCBs. When new substances are added to the candidate list, NextPCB will revise and alert customers if the new substances are present in concentrations above permissible limits under REACH.

The third-party REACH test report verifies that no substances in the Candidate List of Substances of Very High Concern (SVHC) at a concentration above 0.1% by mass are present in our lead-free HASL, ENIG and OSP surface finish PCBs.

|

| NextPCB Lead-free HASL, ENIG, OSP PCB REACH Test Report |

-

PFAS Restrictions

PFAS Restrictions

-

PFAS (perfluoroalkyl and polyfluoroalkyl substances) have recently come under fire as harmful substances found in electronics. Also known as ‘forever chemicals’ due to their resilience to breakdown, the safety and environmental impacts of PFAS have only recently come to light and various regulations are in place or are being proposed to control and reduce the use of PFAS in electronics products.

PFAS include a broad range of chemicals including PTFEs, which are commonly used in PCB laminates for RF circuit boards such as Rogers laminates and some solder mask oils. As shown by the PFAS test report, NextPCB’s standard circuit boards do not contain any concentration of PFAS chemicals above the detectable limit. You can rest assured that your PCBs from NextPCB comply with current and future regulations and minimize any potential health or environmental consequences.

|

| NextPCB Lead-free HASL, ENIG, OSP PCB PFAS Test Report |

-

IPC Standards

IPC Standards

-

In addition to the quality certifications, NextPCB also closely follows key IPC standards such as IPC-6012 and J-STD-001. All PCBs are manufacture and assembled in accordance with IPC-A-600 and IPC-A-610 Class 2 workmanship criteria, with Class 3 available upon request for high-spec applications.

Our robust quality management certifications and practices are a testament to our commitment to quality improvement and ensures we are doing our part to deliver products with the highest possible reliability to our clients and their customers.

For more information on quality assurance or certificates or reports unavailable here, feel free to contact us at support@nextpcb.com.

PCB Assembly

PCB Assembly

Layer Buildup

Layer Buildup

Online Tools

Online Tools

PCB Design-Aid & Layout

PCB Design-Aid & Layout

Mechanics

Mechanics

SMD-Stencils

SMD-Stencils

Quality

Quality

Drills & Throughplating

Drills & Throughplating

Factory & Certificate

Factory & Certificate

PCB Assembly Factory Show

Certificate

PCB Assembly Factory Show

Certificate