What are High-Frequency PCBs?

High-frequency PCBs are PCBs designed to carry high-frequency RF/microwave electromagnetic signals in the 300 MHz to 110 GHz range. Such applications typically require strict circuit layout discipline, specialist materials and careful planning to mitigate signal integrity issues.

Applications that process conducted high-frequency RF signals include wireless communications (Wi-fi 6, 5G mmWave), radar, satellite communications and antennas. The radio frequencies in this range fall under the microwave subset, covering ultra high-frequency (UHF: 300 MHz to 3 GHz) that includes most consumer electronics, GPS, Wi-Fi and 4G, super high-frequency (SHF: 3GHz to 30 GHz) such as 5G mmWave and radar and some of the extremely high frequency (EHF) spectrum that includes 6G, military radar and satellite communications.

High-Frequency Applications and their Frequency Bands and Example Materials

| Application |

Frequency Range |

Band |

Example Materials |

| Wi-Fi 6/6E |

2.4 GHz, 5 GHz, 6 GHz |

SHF |

Rogers RO4835™, Isola FR408HR |

| 5G Sub-6 GHz |

600 MHz – 6 GHz |

UHF/SHF |

Megtron 6, Nelco N4000-13EP |

| 5G mmWave |

24 GHz – 100 GHz |

EHF |

Rogers RT/duroid 5880™, Taconic TLY™ |

| Automotive Radar |

24 GHz, 77 GHz, 79 GHz |

EHF |

Rogers RO3003™, Arlon AD350™ |

| Satellite Comms (L/S-band) |

1–4 GHz |

UHF/SHF |

Taconic RF-35™, Rogers RO4003C™ |

| Satellite Comms (Ka/Q-band) |

26–40 GHz |

SHF/EHF |

Rogers RT/duroid 6002™, PTFE-based |

| RFID/NFC |

125 kHz – 5.8 GHz |

LF/HF/UHF |

Standard FR4, Polyimide flex |

| Phased-Array Antennas |

6–100 GHz |

SHF/EHF |

Rogers RO4730G3™, CuFlon® |

| Military Radar |

1–18 GHz (X/Ku-band) |

SHF |

Rogers RO4830™, Arlon 25N™ |

NextPCB offers PCB manufacturing using ultra-low-loss high-frequency materials from leading laminate manufacturers and experience with hybrid stack-ups, impedance control, via backdrilling, to give you the tools to tackle signal distortions effectively. Check out our high-frequency PCB capabilities or get an instant quote.

Challenges of High-Frequency PCB Design

Designing printed circuit boards (PCBs) for high-frequency applications introduces unique challenges that do not exist in conventional digital or low-frequency analog circuits.

In addition to reflections (from impedance mismatches) and crosstalk (parasitic coupling), high-frequency signals are susceptible to dielectric losses, conductor losses (skin effect), and variable dielectric constants (dispersion).

Above speeds of 1 GHz, high-frequency effects become noticeable. By 6 GHz, high-frequency design principles and standard FR4 laminates become increasingly insufficient to meet signal integrity requirements, necessitating the use of specialized high-frequency PCB materials for controlled impedance and low loss.

As digital data-rates increase beyond 1-6 Gbps, high-frequency distortion phenomena begin to surface and become problematic in high-speed digital circuits as well. In such cases, low-Df, controlled-Dk high-frequency substrates can also be deployed to preserve signal integrity, particularly in multi-gigabit applications (PCIe, Gen4/5, DDR5, 112G SerDes).

Material Selection for High-Frequency PCBs

High-frequency laminates are engineered to minimize signal loss and reduce distortions at microwave frequencies, characterized by low dissipation factor (Df)) and dielectric constants. There are many types of high-frequency laminate materials and composites, but they can be broadly divided into PTFE-based or non-PTFE laminates:

PTFE-based

Also known by the brand name Teflon, PTFE PCBs or Teflon PCBs are made from the polymer Polytetrafluoroethylene (PTFE) and can be reinforced with microfibers or filled with ceramic particles. The prime advantage of PTFE materials are their exceptionally low losses, stable and low dielectric constants. And are often considered the gold-standard for microwave and millimeter-wave PCBs.

Examples of PTFE-based High-Frequency PCB Materials

| Material |

Brand |

Type |

Dissipation Factor (Df) |

| RT/duroid 5880 |

Rogers |

PTFE + Glass |

0.0009 |

| RO3003™ |

Rogers |

PTFE + Ceramic |

0.0013 |

| mmWave77 |

Shengyi |

PTFE + Ceramic |

0.0010 |

Pure-PTFE laminates offer the lowest dielectric loss but are mechanically weak. Ceramic filling or fiberglass reinforcement improves mechanical and thermal stability, but at the expense of low Df.

Non-PTFE based

This includes Rogers RO4003C and RO4530B which are often mistakenly referred to as PTFE laminates. Non-PTFE options include hydrocarbon ceramics, modified epoxies and polyimides. In hydrocarbon ceramics, the ceramic particles give the material exceptional thermal conductivity, high-temperature stability and rigidity. The optimal mechanical properties make them compatible with standard FR4 PCB fabrication methods, thereby simplifying PCB fabrication significantly. Non-PTFE laminates provide cost-effective alternatives to PTFE materials and are highly suited for volume production, but can still be several magnitudes more expensive than FR4.

Examples of Non-PTFE-based High-Frequency PCB Materials

| Material |

Brand |

Type |

Dissipation Factor (Df) |

| RO4003C™ |

Rogers Corp |

Hydrocarbon ceramic |

0.0027 |

| RO4830B™ |

Rogers Corp |

Hydrocarbon ceramic |

0.0037 |

| I-Tera® MT40 |

Isola |

Hydrocarbon ceramic |

0.0031 |

| FR408HR |

Isola |

Modified FR4 |

0.0092 |

For flex and rigid-flex constructions, flexible high-frequency materials such as Pyralux TA (modified polyimide) and LCP (liquid crystal polymers) offer excellent low-loss performance while maintaining flexibility.

The main selling points of high-frequency materials are ultra-low dielectric loss and a stable dielectric constant over a range of frequencies. Ultimately, the decision of which material to use will be determined by the high-frequency performance requirements of the system while also taking into consideration factors such as Dk consistency vs temperature, CTE, temperature and moisture resistance, durability and mechanical properties, ease of manufacture, cost, etc.

NextPCB High-Frequency PCB Materials

NextPCB’s PCB manufacturing capabilities cover both PTFE and non-PTFE Rogers laminates for consumer to extremely high-frequency applications. See the table below for some of the Rogers materials we support, or see our high-speed materials for other low-loss options. Some materials are considered more popular in high-speed applications; however can also cater to high-frequency needs.

| Material Code |

Brand |

Max

Frequency |

Dissipation Factor

Df (@10GHz) |

Dielectric Constant

Dk (@10GHz) |

Tg/°C (non-PTFE)

Td/°C (PTFE) |

CTE (ppm/°C) |

Type |

Copper

Cladding |

Datasheet |

| X |

Y |

Z |

| RO4003C |

ROGERS |

30 GHz |

0.0027 |

3.38 |

280 (TMA) |

11 |

14 |

46 |

Hydrocarbon / Ceramic / Woven Glass |

ED |

RO4003C.pdf |

| RO4350B |

ROGERS |

30 GHz |

0.0037 |

3.48 |

280 (TMA) |

14 |

16 |

50 |

Hydrocarbon / Ceramic / Woven Glass |

ED |

RO4350B.pdf |

| RO3003 |

ROGERS |

77 GHz |

0.0013 |

3 |

500 (TGA) |

17 |

16 |

25 |

PTFE + Ceramic Filling |

ED + RA |

RO3003.pdf |

| RO5880 |

ROGERS |

110 GHz |

0.0009 |

2.2 |

500 (TGA) |

22 |

28 |

173 |

Reinforced PTFE |

ED + RA |

RO5880.pdf |

| RO5870 |

ROGERS |

110 GHz |

0.0012 |

2.33 |

500 (TGA) |

31 |

48 |

237 |

Reinforced PTFE |

ED + RA |

RO5870.pdf |

Get an instant quote

Or inquire for more materials

Fabrication Services for High-Frequency PCBs

In addition to sourcing and processing high-frequency laminates, fabricators can offer many other services to optimize the performance of high-speed and high-frequency PCBs. When choosing a high-frequency PCB manufacturer, be sure to evaluate all their capabilities and experience with high-frequency PCB stack-ups, materials and supporting services.

Impedance Control

For high-frequency and ultra-high-speed digital designs, where tolerance requirements of ±5% are common, standard impedance control practices are inadequate. Test coupon validation does not take into account via stubs, plane cuts or cross-talk in real traces and TDR instruments measure impedance, not signal integrity or power integrity. For RF circuits, S-parameters and phase stability are just as important and a strategy combining simulation and on-board probing, in addition to specialist materials, are essential for optimal signal integrity.

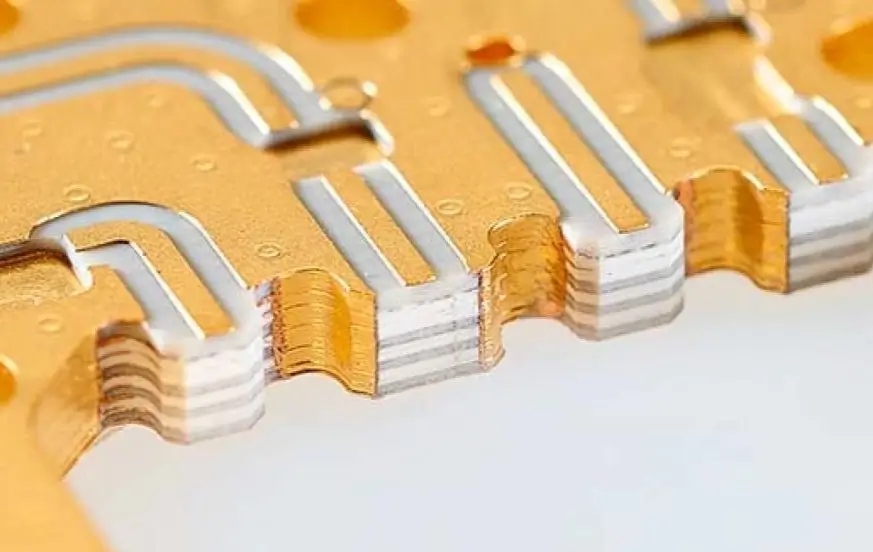

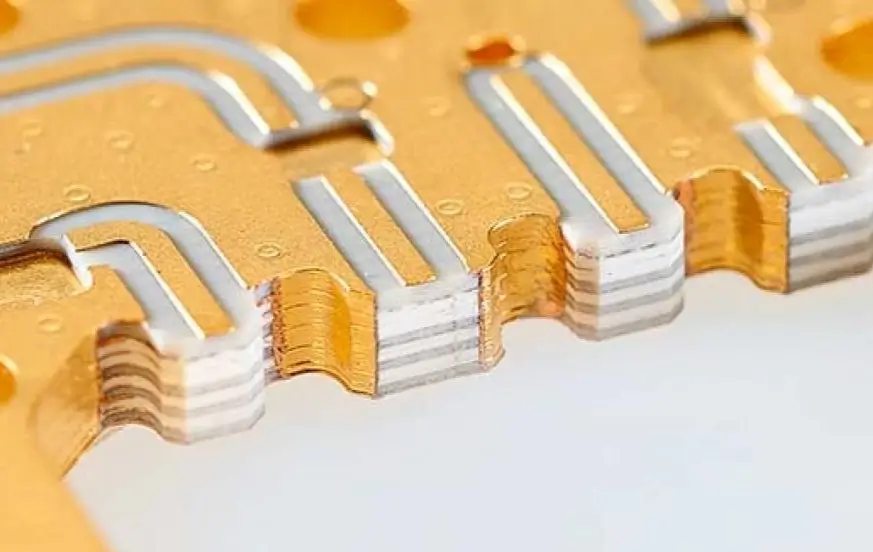

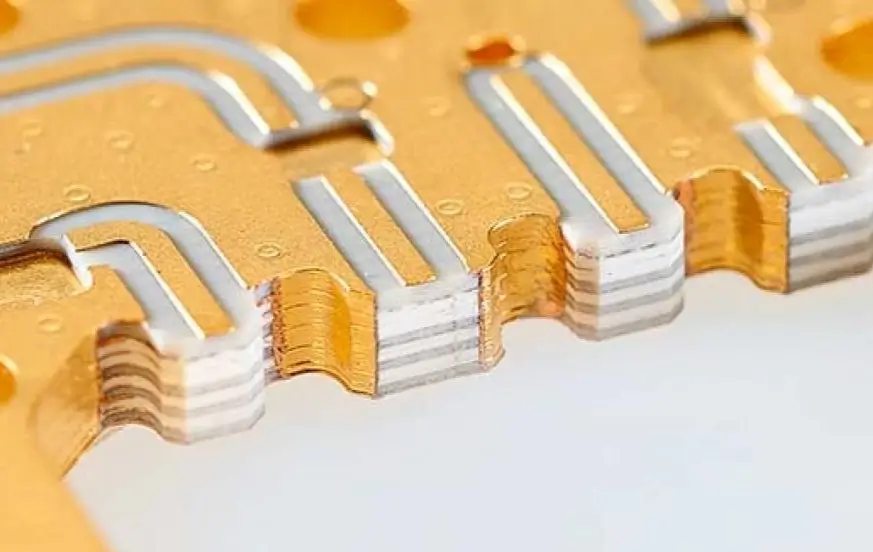

Hybrid Stackups

The greatest downside to specialist high-frequency laminates is the cost. One way of reducing material fees is to design a hybrid stack-up that combines high-frequency laminates with standard FR4 materials. By consolidating all RF signals into a few signal layers, designers can make substantial savings compared to a full high-frequency PCB stack-up. FR4 layers can also impart favorable mechanical properties to the hybrid PCB, such as better rigidity.

For hybrid stack-ups, designers should select materials with similar CTEs and work with fabricators with experience building hybrid stack-ups to reduce the risk of delamination.

Designers choosing a hybrid stack-up should pay special attention to impedance shifts at mixed-material transitions and utilize via stitching appropriately.

Backdrilled Vias/Filled Vias

PCB backdrilling utilizes controlled-depth drilling to remove via stubs, which can be significant sources of signal reflections and losses in high-speed and high-frequency PCB designs. Via backdrilling physically removes the unwanted via excess by mechanically drilling it away from the other side of the PCB, essentially making a blind via structure. High-precision z-axis drilling techniques are required to remove enough material without damaging the functional part of the via.

Likewise, via filling with either conductive or non-conductive epoxy removes the air gap in via barrels, thereby reducing the impedance mismatch. This is advantageous in compact layouts such as dense BGA fanouts, where backdrilling is impractical.

Fine Trace Width Capabilities

For higher impedance targets, finer traces may be required to achieve the required impedance value. Finer trace width capabilities allow for optimal impedance matching without compromising for production limitations. Finer traces also allow for minimal dispersion, which becomes essential in mmWave frequencies (>30 GHz).

NextPCB High-Speed and High-Frequency PCB Manufacturing Capabilities

| Capability |

Details |

| Stack-ups |

Custom hybrid multilayer PCB stack-ups |

| Materials |

High-Speed PCB materials

Low-Dk and Low-Df laminates from major brands including Megatron and Isola, suitable for speeds from 1 to 56 Gbps. See high-speed PCBs

High-Frequency materials

Ultra low-Dk and low-Df Rogers PTFE and non-PTFE laminates and ceramic PCBs. See table for more information

|

| Impedance Control Services |

- Impedance tuning and validation service (single-ended/differential pairs)

- Impedance calculator and stack-up selector tool

|

| Fabrication techniques |

- PCB backdrill

- LP/VLP/RA smooth copper foils

- 3/3 mil trace width/spacing

- Embedded copper/copper coin technology

- Filled vias

|

| Industries/Technologies |

- Telecommunications & Networking: High-speed Ethernet, optical transceivers, 5G mmWave, Wi-Fi 6

- Computing & Data Storage: PCIe, HDMI, USB, NVMe SSDs

- Industrial Electronics: Radar, industrial IoT (IIoT)

|

Get an instant quote

Or inquire for more capabilities

PCB Assembly

PCB Assembly

Layer Buildup

Layer Buildup

Online Tools

Online Tools

PCB Design-Aid & Layout

PCB Design-Aid & Layout

Mechanics

Mechanics

SMD-Stencils

SMD-Stencils

Quality

Quality

Drills & Throughplating

Drills & Throughplating

Factory & Certificate

Factory & Certificate

PCB Assembly Factory Show

Certificate

PCB Assembly Factory Show

Certificate