Support Team

Feedback:

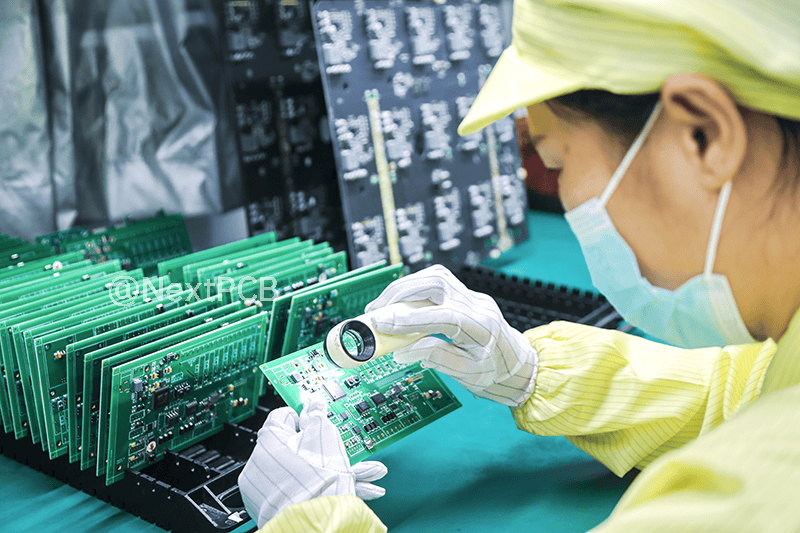

support@nextpcb.comPCB (Printed Circuit Board) plays the role of electrical interconnection carrier and supporting base in electronic devices. Its applications span across consumer electronics, telecommunications, automotive electronics, aerospace, and many other industrial sectors. As the global electronic product market continues to evolve towards customization and rapid iteration, low volume PCB assembly service is increasingly becoming a critical link between product development and mass production.

Low Volume PCB Assembly refers to relatively small orders of PCB assembly. It significantly differs from traditional pcb mass production, typically catering to PCB assembly needs ranging from 1 to 500 units, fulfilling diverse requirements for prototype development, market validation, and niche product production. This model is particularly suitable for:

"Fast Turn" is the core advantage of Low Volume PCB Assembly Service. It emphasizes extremely short lead time, with the turnaround from design file submission to finished assembly typically taking just a few days, and in some urgent cases, can be reduced to 24-48 hours (depending on PCB complexity and component availability). This speed is crucial for:

In electronic product development and small-scale production, different user groups have varied motivations and evaluation criteria for Low Volume PCB Assembly services.

During hardware development, R&D teams often need rapid prototype iteration, with each cycle requiring only 5-50 assembled PCBs. Their key needs are quick turnaround and flexible adjustments. For instance, a medical device developer made seven design changes during the sensor circuit development stage and reduced the development cycle by 60% using low volume pcb assembly services.

Limited funds but urgent need for innovation are typical characteristics of this type of users. They need to minimize the initial investment risk and avoid large-scale inventory backlogs. For example, an IoT startup verified the market response through small-batch trial production (10-100 units), saving 85% of initial capital expenditure.

In fields such as aerospace and high-end medical devices, products have limited demand but require high quality and reliability. For example, a flight control module manufacturer routinely employs low-volume production (annual demand of 200-300 units) while demanding military-grade reliability and full lifecycle technical support.

This service is not just about speed and quantity—it brings multiple strategic advantages to your project:

In a highly competitive market, the first to deliver a new product often gains the upper hand. Fast turn services enable rapid design validation and product testing, significantly shortening the development cycle and ensuring your product enters the market at the optimal time.

Market demands can change unpredictably, and fast turn low volume assembly services offer exceptional flexibility. You can easily iterate on product designs, test different versions, and provide highly customized solutions for various clients without the worry of high mold costs or minimum order restrictions.

low volume production is an ideal phase for comprehensive quality verification. Through rigorous functional testing (FCT test), in-circuit testing (ICT) and reliability testing, we ensure that your products have excellent quality and stability before entering mass production, laying the foundation for subsequent success.

Although unit cost sensitivity is lower in low volume production compared to mass production, cost control remains crucial. NextPCB reduces engineering costs through panelized production, universal test fixture and many automated measures. Our extensive global supplier network also helps mitigate component sourcing premiums, ensuring you receive cost-effective assembly and testing services.

We understand the need to minimize the cycle from design to delivery. NextPCB offers rapid prototyping (SMD delivery as fast as 24–72 hours), parallel engineering (DFM/DFA review and BOM preparation done concurrently), and flexible scheduling with dedicated low-volume lines—ensuring your project isn't delayed by large orders.

Professional users value technical depth and quality assurance. NextPCB provides full Design for Manufacturability (DFM) feedback and free DFA services to help eliminate design flaws early and enhance assembly efficiency. We ensure quality through complete test coverage, including AOI, X-Ray, and free functional testing. Our experienced team also offers advanced support in high-speed signal design, thermal management, and more.

In periods of unstable component supply, supply chain resilience becomes a critical value point. NextPCB has multi-channel component sourcing capabilities and alternative material services to help mitigate potential delivery delays, ensuring your projects continue to progress despite uncertainties. Such as, NextPCB has 600K+ components in stock on HQonline, which can meet some low volume pcb assembly prototyping demand.

Low volume PCB assembly services span the early stages of the product lifecycle: from Proof of Concept (PoC) → Prototype Development → Pilot Run → Market Testing, leading to final mass production. As a professional low volume PCB assembly provider, NextPCB supports your growth by offering seamless services from PCB prototyping to mass production.

In the field of electronic manufacturing services, China has its irreplaceable advantages. Choosing Chinese PCB Manufacturers for fast turn low volume PCB assembly brings you unmatched advantages:

China benefits from a well-established electronics industry chain and economies of scale, with notable advantages in raw material sourcing, labor costs, and production efficiency. This allows you to access high-quality PCB assembly services at more competitive prices, effectively controlling your project budget.

China offers the world's most complete and efficient electronics manufacturing supply chain. From PCB fabrication and component sourcing (including rare or specialized parts) to PCBA assembly, testing, packaging, and logistics—almost every step can be efficiently completed within a single region. This “one-stop” service model greatly shortens lead times and simplifies supply chain management.

With decades of development, China has built strong technical capabilities and extensive practical experience in PCB manufacturing and assembly. It is home to a large number of skilled engineers and technicians, equipped with advanced production facilities aligned with international standards, capable of handling a wide range of assembly needs—from simple boards to complex designs including HDI and BGA packaging.

Chinese PCB manufacturers have a deep understanding of "fast turn" demands and strong execution capabilities. They can respond quickly to customer needs and flexibly adjust production schedules to accommodate urgent projects and changing design requirements, ensuring your project progresses on time.

NextPCB is committed to providing efficient and high-quality fast turn low volume PCB assembly services to customers worldwide. We understand how critical time is to your project, which is why we have optimized every step to ensure your design is swiftly transformed into high-quality finished products.

Our streamlined service process allows you to focus on core R&D while we take care of the rest:

Say goodbye to long wait times—NextPCB offers 24/7 real-time online quotation. Simply visit our website and upload your Gerber files, BOM, and centroid files. Our powerful online pricing system will instantly generate a detailed and transparent quotation. All cost components are clearly listed, allowing you full control over your budget.

After getting the instant quote, you can add your order to the cart. If you have additional customization needs—such as functional testing, special packaging, or expedited production—you can note them directly on the order page or contact your dedicated one-on-one sales engineer. For functional testing, please provide detailed testing instructions to improve accuracy and efficiency.

Our professional engineering team will also conduct a thorough DFM (Design for Manufacturability) and DFA (Design for Assembly) review to ensure your design is flawlessly executed.

With over 600K components in stock, we can fulfill part or all of your component needs. Additionally, our global sourcing network enables us to quickly obtain various electronic components. All incoming components undergo strict IQC to ensure compliance with quality and specification standards.

We will fabricate your PCBs based on your design files and perform assembly using advanced automated SMT production lines and skilled THT (Through-Hole Technology) technicians. Whether it's single-layer, double-layer, multi-layer boards, or complex HDI and BGA designs, we deliver with efficiency and precision.

Quality is at the core of our service. After assembly, each PCBA goes through multiple inspection processes, including:

Once passed inspection, PCBA products are securely packaged with anti-static, moisture-proof, and shock-resistant materials to ensure safety during transit. We cooperate with international couriers like DHL, FedEx, and others to guarantee fast and on-time delivery worldwide.

To help you better understand NextPCB's services, we've compiled some frequently asked questions:

It depends on the complexity of the PCB design, component availability, and order volume. For simple single or double-sided PCB assembly, we can complete the assembly in as fast as 24–48 hours. For more complex projects, shipping is typically within 5–20 working days. Please submit your files for an accurate delivery estimate.

NextPCB supports extremely low minimum order quantities—as low as 1 piece. This is ideal for prototype validation and ultra-small batch custom needs.

Yes. NextPCB provides comprehensive Turnkey PCB assembly services, including component sourcing. Simply provide your BOM file, and we'll take care of procurement and quality control for all components. Also, you can use our online pricing BOM tool to get an estimated price.

Yes. We offer limited free prototyping for both PCB and PCBA. PCB prototyping can cost as little as $0.1 for 10 pieces. For PCBA prototyping, you can get $200 off SMT assembly. If you qualify for the NextPCB Accelerator Program, you may receive full sponsorship for your turnkey PCB assembly prototype.

NextPCB strictly adheres to the ISO 9001 quality management system and IPC industry standards. We are certified by UL, IATF 16949, RoHS, and ISO 13485, ensuring each PCBA meets the highest quality benchmarks. Our quality assurance includes IQC, IPQC, and FQC processes, complemented by AOI, X-Ray, and ICT inspections, and a highly experienced engineering team to deliver superior PCBA products.

NextPCB can assemble a wide variety of PCB types, including but not limited to:

Get Low volume PCB Assembly Quote Online

In project development, time is critical – and NextPCB delivers. We're your one-stop solution for PCB manufacturing and assembly, turning your designs into reality with speed and precision. From high-quality bare boards to advanced PCB Assembly, NextPCB handles both prototypes and mass production. Our expert DFM support ensures top-tier quality and efficiency. Partner with us to streamline your supply chain and accelerate your projects with reliable, trusted PCB solutions.

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now

|

Dimensions: (mm) |

|

|

Quantity: (pcs) |

|

|

Layers: 2 |

Thickness: 1.6 mm |

|

|

|