Support Team

Feedback:

support@nextpcb.comIn SMT production, we sometimes encounter the following situation: before placement, the factory finds that there are relatively large or heavy SMD components on both sides of the PCB, so it is necessary to add a red glue process, which results in additional production costs. How can we avoid these extra costs? I will elaborate it on the following aspects: definition of the red glue process, common application scenarios, HQ Nextpcb’s red glue methods, negative impacts, and optimization suggestions.

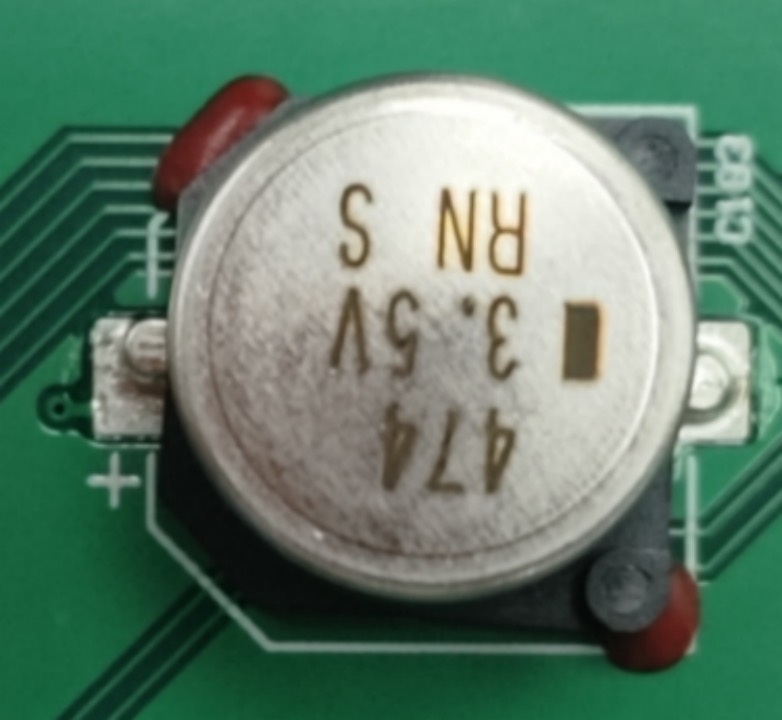

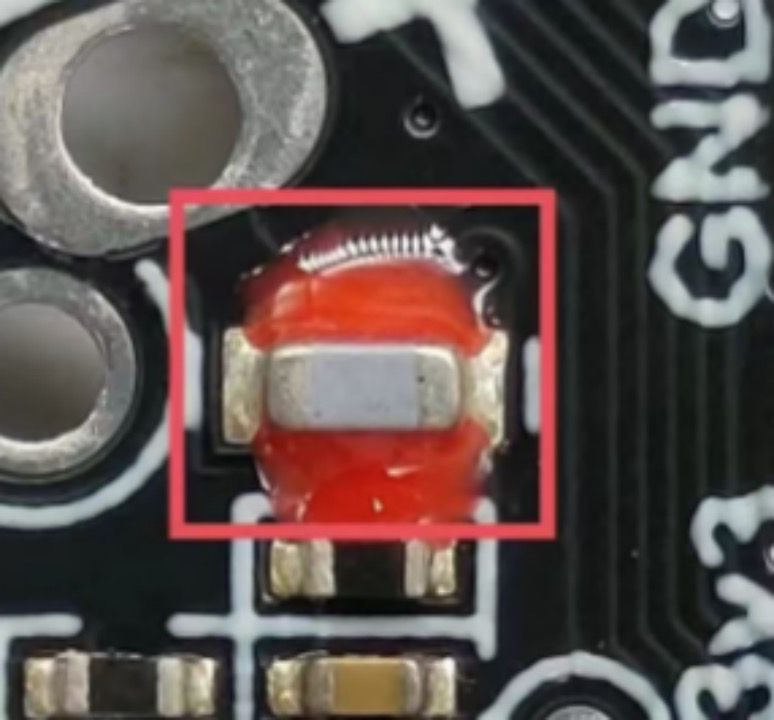

The red glue process refers to the practice in SMT production where red adhesive (usually an epoxy resin glue) is dispensed onto designated locations on the PCB for SMD placement. This is used to temporarily secure surface-mounted components (SMDs) and prevent them from falling off or shifting during subsequent soldering processes.

Solution:

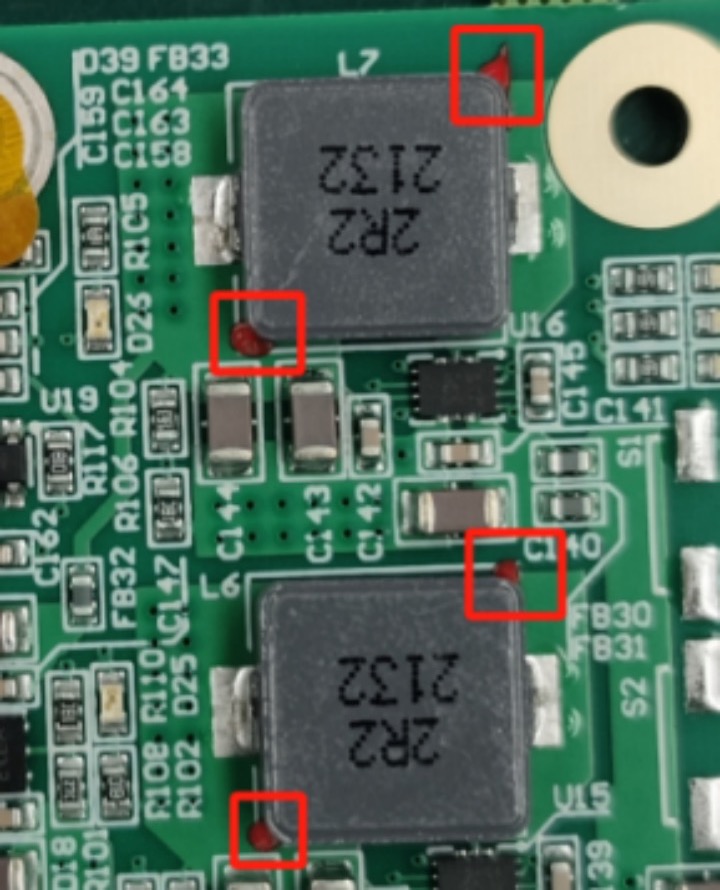

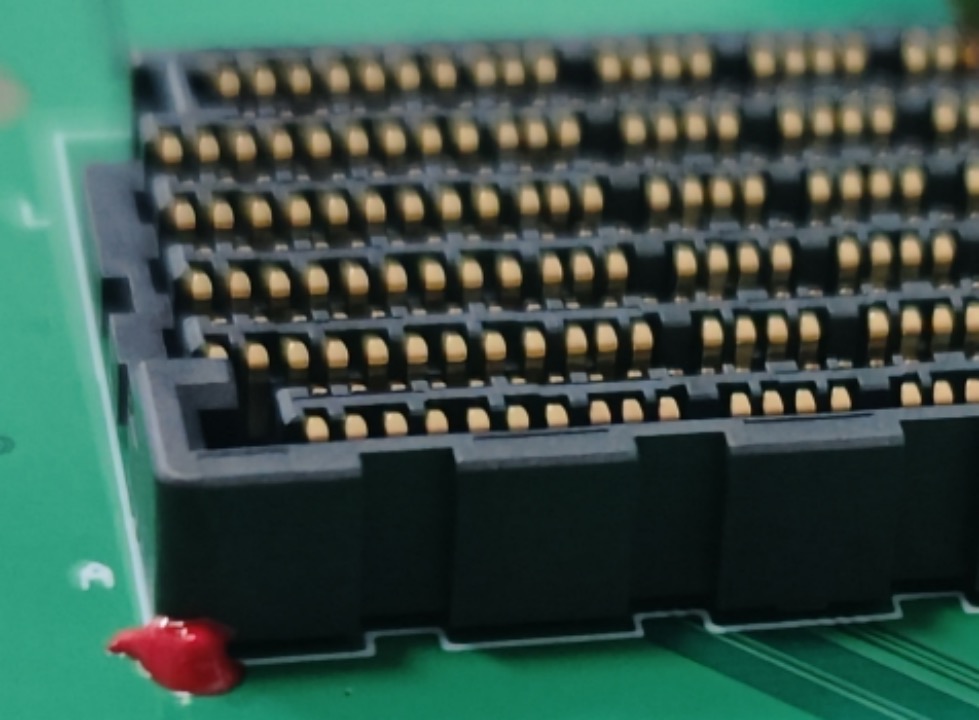

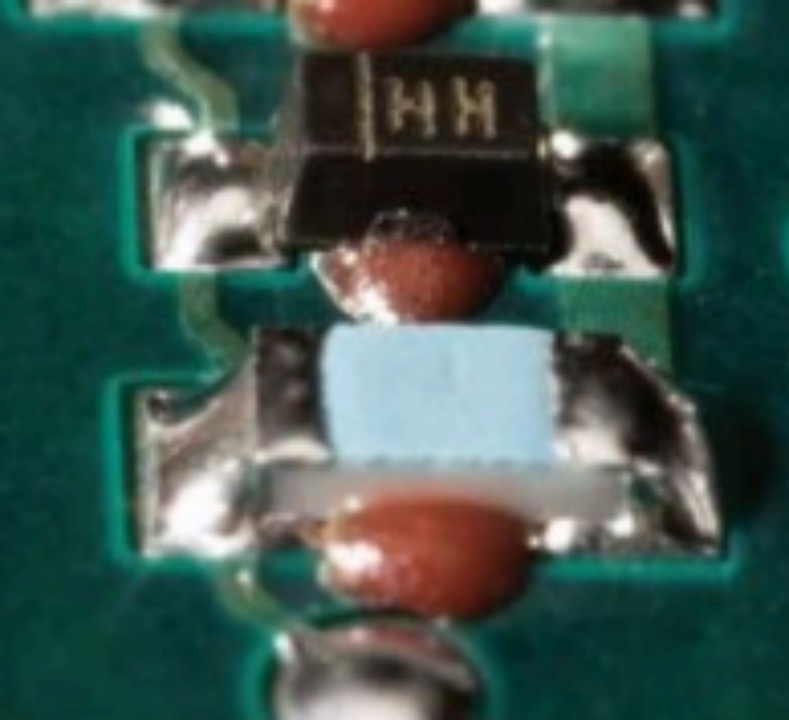

Red glue is applied to the sides of these components, as shown in the pictures below. With red glue, during the second reflow, the components are pre-fixed and will not fall off or shift due to the re-melting of the solder paste.

Common component types: large chip capacitors/inductors/crystals/transformers/SMD sockets, and other heavy SMD components.

These are the more common scenarios for using red glue in our actual production. Of course, there are other situations where the red glue process may be used, but those are not listed here.

A.Strict control over glue amount and position is required; otherwise, component shifting, cold solder joints, and other issues may arise, increasing production complexity.

B.Adding dispensing and curing steps increases the delivery timeline, especially for larger orders.

A.Material cost: Red glue is a consumable, increasing material costs.

B.Labor cost: Extra steps such as dispensing and curing increase labor and management costs.

A.Avoid using components with poor bottom flatness.

B.Avoid using large or heavy SMD components.

C.If such components must be used, give preference to through-hole (THT) types.

Q: When is red glue required in SMT assembly?

A: Red glue is essential when double-sided boards have heavy components prone to displacement during reflow soldering. [Expand with 1-2 sentences]

Q: How does red glue increase SMT production costs?

A: It adds material expenses, labor for dispensing/curing, and prolongs lead times.

For more knowledge about PCB Assembly, you can try to download our complete PCBA Guide.

NextPCB boasts a dedicated team of over 100 manufacturing engineers solely focused on addressing customers' PCB assembly (PCBA) production issues. We offer comprehensive services ranging from prototypes to mass production. Every PCBA order undergoes rigorous review by our expert manufacturing engineers before manufacturing commences. This approach significantly enhances customer efficiency and prevents over 99% of potential manufacturing problems. If you're seeking a reliable manufacturing partner for your products, NextPCB is definitely your optimal choice.

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now

|

Dimensions: (mm) |

|

|

Quantity: (pcs) |

|

|

Layers: 2 |

Thickness: 1.6 mm |

|

|

|