Details about Resettable Fuse

What is the working principle of a polymer resettable fuse?

The polymer resettable fuse consists of a polymer matrix and carbon black particles that make it conductive. Since the polymer resettable fuse is a conductor, current will flow through it. When an overcurrent flows through the polymer resettable fuse, the heat generated (I2R) will cause it to expand. As a result, the carbon black particles will separate and the resistance of the polymer resettable fuse will increase. This will promote the polymer resettable fuse to generate heat faster, expand more, and further increase the resistance. When the temperature reaches 125°C, the resistance changes significantly, so that the current is significantly reduced. At this time, the small current flowing through the polymer resettable fuse is enough to keep it at this temperature and in a high resistance state. When the fault is cleared, the polymer resettable fuse shrinks to its original shape to reconnect the carbon black particles, thereby reducing the resistance to a level with the specified holding current. The above process can be cycled many times.

What is the difference between Rmin, Rmax, and R1max?

Rmin is the minimum resistance specified for the polymer resettable fuse, and this resistance determines the lowest operating current of the polymer resettable fuse. Rmax is the highest resistance specified for polymer resettable fuse. R1max is the maximum resistance that the polymer resettable fuse should reach after the action, and its resistance determines the maximum holding current of the polymer resettable fuse. When the polymer self-recovery fuse action, its resistance (greater than or equal to Rmin and less than or equal to Rmax) will rise to less than or equal to R1max.

How much voltage drop will there be on a polymer resettable fuse?

This depends on the specific circuit. Generally speaking, if you know the resistance and the current in the equilibrium state, the voltage drop can be calculated. The maximum voltage drop of the polymer self-resetting fuse is calculated using the resistance R1max; the typical voltage drop can be the resistance Rmax or the average value of Rmin and R1max if Rmax is not provided. If Iop is the normal operating current and Rps is the resistance of the polymer resettable fuse (R1max, (Rmax or (Rmin + R1max)/2)), the voltage drop on the polymer resettable fuse in the circuit is: Vdrop = Iop x Rps

Can polymer resettable fuses be used in series?

This has no practical meaning. Because there is always one that will act first, and the others will not protect the circuit.

How to calculate the resistance of polymer resettable fuse operating state?

The resistance of the polymer self-recoverable fuse operating state depends on the specific type and the voltage and power on it. It can be calculated by the following formula: Rt = V2/Pd

How many times can the polymer resettable fuse operate under the maximum voltage and impulse current?

Each polymer resettable fuse has a specific working voltage and withstands a specific impulse current. UL stipulates that the polymer resettable fuse must still show the PTC effect after 6,000 operations. The SN/SF polymer resettable fuse used in communication equipment stipulates that its various performance parameters are still within the original range after at least a dozen or as many as hundreds of actions under the maximum voltage. Designers should recognize this point: Polymer resettable fuses are used for protection, not for situations where their non-stop action is regarded as a normal working state.

How soon can the polymer resettable fuse be restored after it is activated?

The time taken for the polymer self-resetting fuse to return to its low resistance state after the action is affected by the following factors: the type of polymer self-resetting fuse; how it is mounted or fixed; the ambient temperature; the internal cause and duration of the action. Generally speaking, although many will recover within a few seconds, most polymer resettable fuses will recover within a few minutes.

How long can the polymer resettable fuse stay in the operating state without being damaged?

UL stipulates that the polymer resettable fuse must stay at the maximum voltage for 1000 hours without losing its PTC characteristics. The longer the time that the polymer resettable fuse stays in the operating state, the more likely it is that its resistance value cannot be restored, and thus may not meet its initial definition. The time that each polymer resettable fuse can stay varies with the fault event and type.

Can polymer resettable fuses be classified according to resistance value?

Some of our polymer resettable fuses are classified according to resistance value and then provided to users. Mainly used in polymer resettable fuses in the communication field.

What is the impact of the encapsulation of polymer resettable fuses?

Generally speaking, even though some customers have successfully encapsulated our products, we still do not advocate. When packaging, we must pay attention to the selection of materials and the method of bending packaging. If the packaging material is too hard, the polymer resettable fuse will not be allowed to expand according to the design requirements, so that it cannot work according to the design requirements. Even if the packaging material is soft, the heat transfer characteristics of the polymer resettable fuse will be affected, making the polymer resettable fuse behave differently from the design requirements.

What is the effect of pressure on polymer resettable fuses?

Pressure will affect the electrical performance of polymer resettable fuses. If the pressure during the operation is too large to limit the expansion of the polymer resettable fuse, the polymer resettable fuse will not operate as specified.

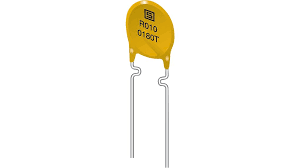

How to determine the type of polymer resettable fuse from the appearance of a sample?

Most polymer resettable fuses will be printed with trademarks and models. Various standard polymer resettable fuse product models are listed in the company's product manual. In addition, the company also customizes products for users to meet their special requirements

What is the maximum ambient temperature for polymer resettable fuses?

The polymer resettable fuse under working conditions depends on the product type. For most of our products, this range can reach 85°C, some can be as high as 125°C (such as SN/SF), and some can be as low as 70°C (LP-CW). Some polymer resettable fuses under non-operating conditions can withstand short reflow soldering temperatures (LP-SM, LP-MSM, SD).

Can a polymer resettable fuse reset itself? How to recover? How fast is it?

Yes, once the fault is cleared and the polymer resettable fuse has a chance to cool down, it will reset itself. Cooling allows the carbon black particles to contact and reconnect, thereby reducing electrical resistance. Generally, the method to cool the polymer resettable fuse is to cut off the energy supply of the protected equipment and cut off the fault current so as to allow the polymer resettable fuse to cool. Polymer resettable fuses should be distinguished from bimetal devices that are also capable of resetting. Even if the fault event is not cleared, a typical bimetal device will recover automatically, thereby switching between the fault event and a protected state that may damage the equipment.

The polymer resettable fuse will remain in a high resistance state until the fault event is cleared. The time it takes for a polymer resettable fuse to reset to a low resistance state depends on a large number of factors: the type of polymer resettable fuse; how it is mounted or fixed; the ambient temperature; the internal cause and duration of the action. Generally speaking, although Many will recover within a few seconds, most polymer resettable fuses will recover within a few minutes.

Can polymer resettable fuses perform state transitions? How can I keep the state unchanged?

When the fault event is not eliminated, the polymer resettable fuse will not change between normal and operating states. When the polymer resettable fuse operates, its resistance changes from low to high. In the high-impedance state, a small amount of fault current still exists. This small fault current is sufficient to keep it in a high-impedance state. When the fault is cleared, the polymer resettable fuse can be cooled back to a low resistance state.

What is the difference between IH and IT? Why is it different?

IH is the highest current that does not trigger a sudden resistance jump in still air (from 20°C to 25°C depending on the temperature of the product), that is, the highest operating current at room temperature. IT is the minimum current when the polymer resettable fuse operates in still air (from 20°C to 25°C depending on the temperature of the product), that is, the minimum fault current at room temperature. For most of our products, the ratio of IT to IH is 2:1, for some products it may be as low as 1.7:1, and for some products it may be as high as 3:1. The difference in materials and production methods and the change in resistance after the action will determine this ratio.

Under what circumstances does a polymer resettable fuse reset?

The resetting of polymer resettable fuses is a function of current, voltage, and temperature. Polymer resettable fuses often start to reset when the temperature drops below 90°C (it can be said that the polymer resettable fuse has reset when the temperature is lower than 80°C)

The polymer resettable fuse will swell during operation, will it return to its original state when resetting?

The polymer resettable fuse in the operating state will expand and will return to its original size and shape after cooling and resetting. Although its resistance value will not return to its original value, it will return to a value that meets its definition.

What temperature can the polymer resettable fuse reach?

The maximum surface temperature of the polymer resettable fuse can reach 150°C, but the typical surface temperature is 110°C.

PCB Assembly

PCB Assembly

Layer Buildup

Layer Buildup

Online Tools

Online Tools

PCB Design-Aid & Layout

PCB Design-Aid & Layout

Mechanics

Mechanics

SMD-Stencils

SMD-Stencils

Quality

Quality

Drills & Throughplating

Drills & Throughplating

Factory & Certificate

Factory & Certificate

PCB Assembly Factory Show

Certificate

PCB Assembly Factory Show

Certificate