Automobile Industry Development

The rapid development of the electronics industry has promoted many industries. In recent years, electronic products have become more and more widely used in the automotive industry. The traditional automobile industry has made more efforts in mechanics, power, hydraulics, and transmission. However, the modern automobile industry relies more on electronic applications that play an increasingly important and potential role in automobiles.

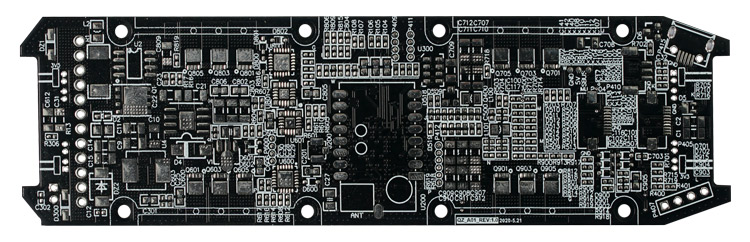

Automatic electrification is all used for processing, sensing, information transmission, and recording, which can never be achieved by printed circuit boards (PCB). Due to the needs of automobile modernization and digitization, as well as people's requirements for automobile safety, comfort, simple operation, and digitization, PCBs have been widely used in the automotive industry, from ordinary single-layer PCBs, double-layer PCBs to complex multilayer PCBs.

Applications and types of PCBs in the automotive industry

Since there are many different types of electronic systems in today's automobiles, the types of PCBs required for automotive electronics vary greatly. The same car may require different HDI PCBs and rigid-flex PCBs to complete system operation. As people demand more accessories and functions for automobiles powered by electronic components, the demand for various types of automotive PCBs is increasing.

The manufacturer of automotive circuit board not only need to provide various types of PCBs but also must be able to provide materials that can withstand rigorous use and protection so that the board could support a longer life cycle

NextPCB provides you with highly reliable automotive circuit boards

We can produce any type of printed circuit board required for automotive applications. NextPCB has passed IATF 16949, ISO9001, ISO14001, UL, RoHS, REACH, and other certifications, so the PCB is an absolutely durable, reliable, and durable printed circuit board. At the same time, we also have 3 major manufacturing plants: PCB prototyping, PCB manufacturing, PCB assembly, therefore, we can provide you with turnkey service, and the price is also competitive.

PCB Assembly

PCB Assembly

Layer Buildup

Layer Buildup

Online Tools

Online Tools

PCB Design-Aid & Layout

PCB Design-Aid & Layout

Mechanics

Mechanics

SMD-Stencils

SMD-Stencils

Quality

Quality

Drills & Throughplating

Drills & Throughplating

Factory & Certificate

Factory & Certificate

PCB Assembly Factory Show

Certificate

PCB Assembly Factory Show

Certificate