The outstanding requirements of the PCB power supply are high reliability and high plating uniformity. The PCB power supply adopts a brand-new power supply operation and monitoring circuit with large redundancy, which can ensure the reliable operation of the power supply. The uniformity mainly depends on the output waveform of the power supply. The power supply also has the functions of reducing working time, saving raw materials, and keeping costs down.

The PCB power supply uses high-quality imported IGBTs as the main power devices and uses ultra-microcrystalline (also known as nanocrystalline) soft magnetic alloy materials as the main transformer core. The main control system adopts multi-loop control technology, and the structure adopts anti-salt spray acidification. The power supply has a reasonable structure and strong reliability. The power supply has become an updated product of the SCR power supply due to its small size, lightweight, high efficiency, and high reliability.

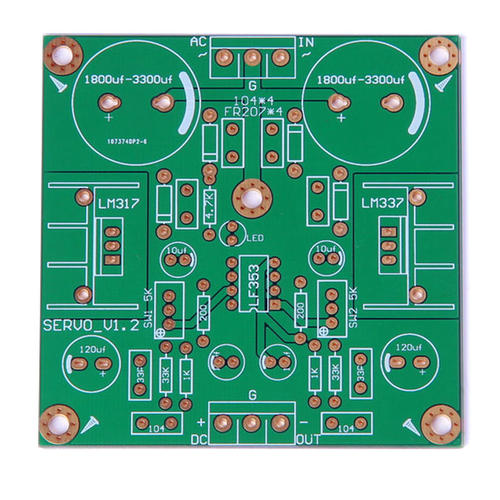

Main features of the power supply PCB

1. Small size and lightweight:

The volume and weight are 1/5-1/10 of the SCR PCB power supply, which is convenient for you to plan, expand, move, maintain, and install.

2. Great energy-saving effect:

The switching power supply adopts a high-frequency transformer, and the conversion efficiency is greatly improved. Under normal circumstances, the efficiency of SCR equipment is increased by more than 10%, and the efficiency of SCR equipment is increased by more than 30% when the load rate is below 70%.

3. High output stability:

Due to the fast response speed of the system (microsecond level), it has strong adaptability to network power and load changes, and the output accuracy can be better than 1%. The switching power supply has high working efficiency, so the control accuracy is high, which is beneficial to improve product quality.

4. The output waveform is easy to modulate:

Due to the high operating frequency, the relative processing cost of output waveform adjustment is relatively low, and the output waveform can be changed more conveniently according to user process requirements. This has a strong effect on improving worksite efficiency and improving the quality of processed products.

NextPCB provides high-reliability power PCB

A technical team with 15 years of experience in the PCB industry, familiar with the key control points of power supply PCB. Select high-quality raw materials: Shengyi, Kingboard Class A materials to create high-quality boards with high reliability; at the same time, introduce high-precision equipment such as Taiwan Dongtai Drill Hole machine, Japanese famous machine (MEIKI) vacuum heat-press, Taiwan Mingming electroplating line, cosmic horizon, high-end LDI laser exposure machine, digital inkjet character printer, German imported flying probe tester, and other advanced equipment, passed ISO9001, ISO14001, IATF16949 (automotive certification), UL multilayer board, CQC, REACH, GB-T29490 and other full series of the quality management system, environmental management system.

If you need high-quality printed circuit boards for power supplies, please contact us immediately. We provide manufacturing and assembly services for power supply PCBs. This means that you can obtain the final product directly from our factory without being disturbed by logistics, thereby reducing the speed of the process.

PCB Assembly

PCB Assembly

Layer Buildup

Layer Buildup

Online Tools

Online Tools

PCB Design-Aid & Layout

PCB Design-Aid & Layout

Mechanics

Mechanics

SMD-Stencils

SMD-Stencils

Quality

Quality

Drills & Throughplating

Drills & Throughplating

Factory & Certificate

Factory & Certificate

PCB Assembly Factory Show

Certificate

PCB Assembly Factory Show

Certificate