Considering that the intro of automated PCB setting up as well as element lead soldering, wave soldering has actually been the mainstream technique of using solder immediately downside of PCBs. Swing soldering uses a stainless-steel bathroom loaded with liquified solder, a solder burner, and also an agitator to create a fixed wave throughout the surface area of the fluid solder. Significant experience is called for to keep the solder in prime problem, at the proper temperature level, and also wave characteristics to attain the most effective soldering outcomes.

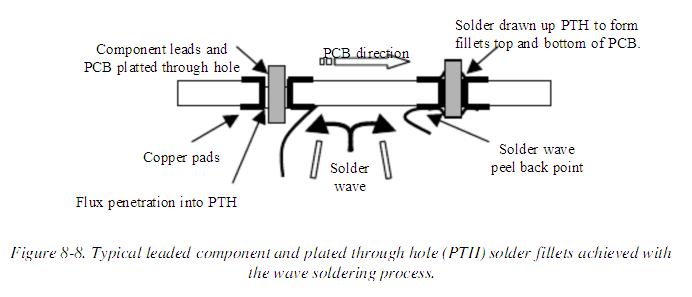

The following image reveals the waveform as the PCB overlooks it.

The PCB wave soldering has five steps: fluxing, preheating, solder wave, cool off, and cleaning (it is the quality control plan of the PCB assembly manufacturer).

Purpose of PCB fluxing

The major objective of the change is to tidy as well as prepare the element leads, PCB layered via openings (PTH), and also pads by getting rid of oxide and also substance movies that hinder the solder moistening procedure. Some changes are very energetic as well as harsh whereas others are extremely moderate or gently energetic. Quality "R" has an extremely reduced task, as well as quality "SRA" is extremely highly energetic. Quality RMA is one of the most usual as well as classified as slightly energetic. Solid changes often tend to leave harsh deposits on the part as well as PCB, needing expensive cleaning and also cleaning up procedures. Long-term, these harsh deposits damages elements and also present unreliability of the item in later life. Change can be used in numerous methods, yet spray fluxing is most usual. The following picture shows a regular spray fluxing procedure.

PCB Pre-heating

Numerous systems include an air blade after the change application to get rid of excess change as well as pressure change inside the platted via openings. The preheat phase in wave soldering is really comparable to that in surface area install manufacturing aside from the plan of the heating units, as displayed in the next picture.

Pre-heating is attained by blowing air via perforated heating units onto the bottom of the board. The temperature level of the PCB, as well as parts, enhances gradually up until at the end of the preheat passage, the topside of the PCB and also elements are in between 100 as well as 150ºC. This minimizes thermal shock when the PCB, as well as parts, reach the liquified solder wave. Thermal shock to the PCB in wave soldering is a significant problem. If the differential in between the topside and also the lower side is undue, the board will certainly peel as well as the warp, creating high mechanical tension on the elements when the solder has actually strengthened. The preheat phase likewise triggers the change, to make sure that all steel components are tidy before getting to the warm solder wave.

PCB solder wave and cool off

The temperature level account with the full procedure is revealed at the next picture. The temperature level decrease as the board departures the preheat phase is created, on some makers, by the problem in position the wave instantly at the leave of the preheat passage. The temperature level autumn can be 20 - 40 ° C, which might be considered for huge incorporated circuits. Interest in thermal profiling or any type of temperature level tour benefits factor to consider for the part as well as its long-term integrity. As explained in Phase 2, all physical measurements of a ceramic part will certainly increase or acquire around 6 ppm per level centigrade, whereas an FR4 board product will certainly transform by 14 ppm per level centigrade. Because of these distinctions, the element discontinuations will certainly be under stress when the solder strengthens as well as the finished setting up cools off. Elements are normally created for this yet excellent treatment needs to be taken with using huge elements as well as the option of PCB laminates, relative to matching TCE. Such failing settings are related to discontinuation tears as well as solder joint cracks. The cool phase in wave soldering systems is possibly based upon all-natural air conditioning to ambient or regulated.

PCB Assembly

PCB Assembly

Layer Buildup

Layer Buildup

Online Tools

Online Tools

PCB Design-Aid & Layout

PCB Design-Aid & Layout

Mechanics

Mechanics

SMD-Stencils

SMD-Stencils

Quality

Quality

Drills & Throughplating

Drills & Throughplating

Factory & Certificate

Factory & Certificate

PCB Assembly Factory Show

Certificate

PCB Assembly Factory Show

Certificate