Support Team

Feedback:

support@nextpcb.comFlexible printed circuit (FPC), also known as soft circuit board, flexible circuit board, is a highly reliable and excellent flexible printed circuit board made of polyimide or polyester film as the substrate. It has the characteristics of high wiring density, light weight, thin thickness and good bending.

FPC material selection is particularly critical, which is related to the actual use effect of FPC and the cost of FPC.

Side key: 18/12.5 double-sided electrolytic copper (except special ones); main button: 18/12.5 double-sided electrolytic copper (except special ones); this specification of material is more suitable for making this type of board. There are no special requirements for the bending of side keys and main keys. It is OK to weld them on the motherboard and fix them. However, it must be ensured that there is no abnormality after bending back and forth more than 8 times before use.

The thickness of the key position has strict requirements, otherwise it will affect the feel of the key, so the total thickness requirements of the customer must be met.

Connecting wires: 18/12.5 double-sided electrolytic copper (except for special ones); this specification of material is more suitable for making this type of board. The main function of this type of FPC is to connect, and there are no special requirements for bending. Just weld and fix the two ends, but be sure to bend back and forth more than 8 times without abnormalities before use.

Double-layer slide cover: 1/30Z single-sided electrolytic copper without glue. This material is soft and ductile and suitable for making this type of FPC.

Double-sided slide cover: 1/30Z double-sided electrolytic copper without glue. This material is soft and ductile and suitable for making this type of FPC.

After many tests and verifications, the slide cover made of 1/30Z double-sided electrolytic copper without glue will have a better life than the double-layer board made of 1/30Z single-sided electrolytic copper without glue. If there is no problem with the structure, it is recommended that customers try to design the FPC into a double-sided slide cover. In terms of cost, the cost of using 1/30Z double-sided electrolytic copper without glue will increase by about 30% compared with the cost of using 1/30Z single-sided electrolytic copper without glue. However, the production yield will be improved by using this material, and the test life can also be improved, and the stability of this type of board can be guaranteed.

Multilayer board: 1/30Z electrolytic copper without glue, this material is soft and ductile, suitable for making this type of FPC. After multiple tests, the flip board made without structural problems can pass the test.

A. Ordinary boards that do not require SMT can use adhesive tape that is not resistant to high temperatures. (such as side key boards)

B. Those that require SMT must use high-temperature resistant adhesive tape. (such as key boards that require SMT)

Ordinary conductive adhesive is suitable for those with low conductivity requirements. (such as ordinary key boards)

Those with better conductivity are suitable for those with high conductivity requirements and must use adhesive tape. (such as special keypads, etc.), but we generally do not recommend the use of this adhesive tape because the price is too high.

This conductive cloth has good conductivity but not very good viscosity, and is generally suitable for keypads.

High-strength conductive material, generally used to paste steel sheets, but we do not recommend this conductive pure glue because the price is too high.

Gold surface reinforcement is bonded with pure glue, and holes are drilled for reinforcement and pure glue, and then silver paste is dripped from the hole to make the board and reinforcement well grounded. This method has a resistance value close to 0 ohms. It is currently an ideal production method, and its main application scope is multi-layer boards with connectors (required to be grounded) and other types of boards with grounding and connectors. Our company recommends customers to use this production method!

Suitable for plug boards with plug-in fingers. This type of board must use PI reinforcement. It is recommended not to use PI reinforcement for other types of boards and other positions except the plug position. This material is not strong enough and the price is also high.

FR-4 reinforcement is used for most boards such as buttons and side keys, but this reinforcement must be pressed with pure glue to play a better reinforcement role.

Steel sheet reinforcement is suitable for multi-layer boards and single and double-sided boards with connectors. This reinforcement has a relatively high hardness, the produced board is relatively flat, and SMT is also easier to operate. It is recommended that all types of boards with connectors can be reinforced with steel sheets (except for gold surface reinforcement for grounding).

Via must not be designed in the bending area. If it is designed in the bending area, this FPC will 100% fail the test.

The grounding hole of the electromagnetic film must not be designed in the bending area and sliding area. If it is designed in the bending area, it will seriously affect the bending and sliding life of the FPC.

Text cannot be designed in the bending area and sliding area. If it is designed in this area, it will seriously affect the bending and sliding life of FPC.

Pure glue window opening should be as close as possible to the two ends of the bending area and sliding area to ensure the life of this product

The via in the center of the key should be moved to the edge, not in the center of the key, to avoid poor contact of the key during use.

Key size design: Keys are divided into round keys and oval keys. The sizes of DOME sheets are 3, 4, 5 and 3×3, 3×4, 4×5. The keyboard of FPC is 0.3mm larger than the dome sheet on one side. The keys on FPC are at least 3.6, 4.6, 5.6, 3.6×3.6, 3.6×4.6, 4.6×5.6 respectively. If the size is not enough, corresponding compensation should be made.

Line requirements for the bending area: Vias in the bending area should be moved to the non-bending area to avoid hole breakage during the bending process; Lines in the bending area are best in straight lines, and the lines should be as thick as possible.

The main key light/resistor/capacitor pads should be compensated according to the standard design.

The minimum line width of the key connection line is 0.2mm, and a smooth inner drop transition should be added at the junction with the key, so the pads should all be added with inner drops.

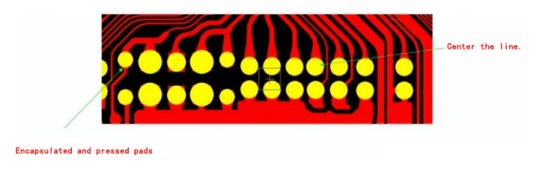

The key receiver and microphone pads are generally hand-welded, so if the operation is improper, the pads are easy to fall off, so the pads must be enlarged to allow the package to press (green is the package window)

Under permitted conditions, the main key connector is elongated by 0.2mm on one side to allow the package to press, and the connected fingers are modified to be connected outside the package window as much as possible, and the grounding fingers are made as large as the standard fingers to avoid tinning and affecting the SMT quality.

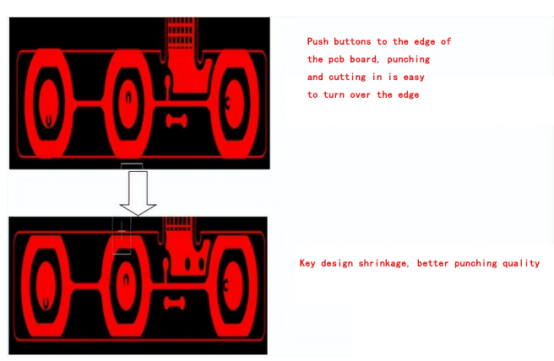

If the side button reaches the edge of the board, it should be retracted by more than 0.15 to prevent the copper foil from turning over.

If there is a wire from the side button to the button, it is best to move it to the reverse side. (Communicate well with the customer)

The encapsulation window is 0.1mm larger than the minimum pad. If it can be modified, try to increase it to avoid alignment difficulties.

The light/capacitor/resistor window on the main key allows the encapsulation to press the pad to prevent the pad from falling off. As shown in the figure below: (green is the encapsulation window)

If there is a wire between pads, try not to open the window (except in special cases) to avoid soldering and affecting SMT quality. (Green is the encapsulation window)

The key board is not bent many times, mainly for assembly bending, but if the bending area is not designed properly, it will also affect installation and use. The following points need to be considered during the design process.

Press-weld fingers: The openings of the fingers on the front and back sides should not be designed on the same straight line to avoid stress concentration. The openings of the fingers on the front and back sides should be staggered by 0.5mm (the side soldered to the motherboard is short, and the side with tin is long). The front end of the finger should be designed to be serrated, and tin leakage holes should be added. The tin leakage holes should be staggered as much as possible.

The bending area should be made soft, and the large copper sheet should be made into a mesh or copper removal and encapsulation removal.

The main key grounding position should be made soft, the front side should be made into a grid, the back side bending area should be removed from copper, and the encapsulation should be removed, but vias should be added at the grounding point (green is the encapsulation window)

All right angles in the outer shape should be chamfered to improve the bearing capacity of FPC during sliding. The circuit in the sliding area should be as straight as possible (as shown in Figure a). If it cannot be horizontally straight, it should be rounded (as shown in Figure b). If the circuit can be compensated, it should be compensated, as shown in the following figure: (green is pure glue window)

The vias of the slide cover cannot be in the sliding area, otherwise it will affect the bending property. The vias should be moved away when they are close to the bending area.

For boards with plugs, the target hole must be placed on the side of the finger, the IC position with the connector should be stretched as much as possible and pressed by the encapsulation, and the plug position must be placed in the center of the finger.

Sliding cover plates generally have shielding design requirements, and can be shielded with tin-aluminum foil and silver paste (some use a separate shielding plate, generally used on flip phones). Silver paste is prone to fall off when the number of bends is high, so when the number of bends is high, it is recommended that customers use tin-aluminum foil for shielding. The tin-aluminum foil must be grounded to achieve a shielding effect. The grounding position of the tin-aluminum foil should be made in the non-sliding area at both ends as much as possible. If it can only be grounded in the sliding area, the grounding position should not be made on the outside as much as possible. The position of the tin-aluminum foil at both ends should exceed the pure glue position.

Flash plating process is required: In order to ensure the softness of the sliding area, the copper plating and thickening of the copper foil need to affect the bending life. Flash plating requirements:

Except for the bending area, all other areas are copper-plated, but it must be larger than the pure glue window. The joint cannot be made in the layered area and is wavy to prevent stress concentration (yellow is the secondary copper plating area)

Note: Flash plating requires 3 minutes, and the secondary copper plating area must indicate the area.

The large copper foil in the bending area should be grid-processed as much as possible (to communicate with the customer). If there is no circuit on the back, it should be encapsulated.

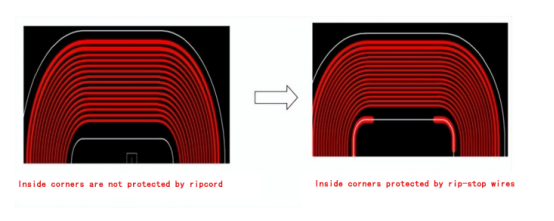

The right angles in the outer shape should be chamfered, and the area in the bending area should be rounded. The circuits in the bending area should be routed in straight lines and arcs as much as possible. When conditions permit, anti-tear lines should be added, and there should be no vias in the bending area. As shown below:

Arcs and straight lines are preferred in the bending area, as shown below:

Anti-tear lines need to be added to the bend area of the outer shape for tear-proof protection.

Pure glue windows should be opened as large as possible. The locations with grounding angles generally have installation bending area requirements and need to be soft. For multi-layer boards, the grounding angle must also consider the thickness of the grounding copper. Too thick is not easy to weld.

Grounding angle modification (such as six-layer board), the following figure is a schematic diagram of the grounding angle modification of a six-layer board. The grounding angle pure glue area is as large as possible, and only three layers of grounding angle copper are left (top bottom layer and one inner layer, and the other layers are copper-free). The grounding wire is on the inner layer and vias are added. The top and bottom encapsulations are removed, so that the flexibility of the grounding angle and the copper thickness of the grounding point can be guaranteed to the greatest extent.

The connector IC is stretched to both sides as much as possible. It is best if the encapsulation can be pressed. The encapsulation is widened outward within the permitted range to facilitate SMT welding, and a 0.3mm MARK point is added to the diagonal. The specific method refers to the keypad connector method.

When drilling holes with pure glue, all holes on the soft board (holes on the soft board when pure glue is applied) should be drilled out to prevent pure glue from overflowing and affecting circuit production.

The tin-aluminum foil must be grounded, and the grounding position should be in the non-bending area as much as possible. The tin-aluminum foil should cover the glue-free area. The tin-aluminum foil must be more than 0.8mm away from the IC package window position for welding to prevent welding short circuit.

The double-drilling data pin holes of multi-layer flip board must be fool-proof, and they must be cut separately from the shape positioning holes.

The pure glue window of multi-layer flip board is at least 0.8mm away from the via hole. All drilling holes cannot be drilled into the glue-free area. When adding alignment holes and auxiliary holes in CAM, the pure glue window must be opened.

For boards with layers, a test must be done. Encapsulation/tape/reinforcement covering the outer tube position holes must be made to give way, and the minimum give way hole is 3.0 (outer positioning hole 2.5)

The inner layer circuit of the multi-layer flip cover board should be as large as possible from the outer shape, generally more than 0.25mm, and the outer layer is generally more than 0.25mm (minimum 0.0.2mm) to prevent the circuit from being hit.

The four pads at both ends of the connector IC must be enlarged to 1-2 times the middle pad (based on space permission). This design can prevent the connector from falling off during assembly and use.

The windows on the front and back sides of the pressure welding finger end are staggered by 0.5mm, and the front and back encapsulations must press the fingers to prevent the fingers from breaking and increase the tin leakage holes and half holes to enhance solderability.

The independent finger at the end of the thin finger should be elongated to allow the package to press more than 0.3, and the outer end should extend 0.5mm to improve the adhesion of the finger on the board to prevent the edge from turning over during die punching.

The finger position in the middle of the LCD panel should be pressed by more than 0.3mm.

The pad opening on the circuit is generally drilled, and the four corners of the pad should be pressed. The routing in the middle of the pad should be centered (the distance from the encapsulation window is equal). The size of the pad should meet the standard requirements, and compensation should be made if it does not meet the requirements.

The encapsulation should be removed from the bending area on the back of the thin finger, and the encapsulation should be left on the back of the thin finger to strengthen the finger end.

The large copper foil in the bending area is changed to grid processing, and the encapsulation is removed where there is no wireless type in the bending area.

To facilitate SMT, the LCD panel requires adding MARK points inside the board, with a size of 1.0 (encapsulation window 1.5) placed at both ends of the component position, and the position is as follows: size 1.0

For plugs, pay attention to the equal distance between the left and right sides of the plug. If they are not equal, adjust them and use target shooting. The target ring must be made on one side of the plug.

The position and orientation of the mold's thin fingers and plugs must be indicated. For plugs, important dimensions must be indicated. The shape mold requires a jump step mold (punch the thin fingers first, and add jump step holes to the data). For the positions with reinforcement, the position and orientation must be indicated.

The mass production of LCD panels requires continuous shipment. The connection points are required to be added at the appropriate position. The reinforcement position is not added as much as possible. The finger position/plug position/bend position/offline or position close to the pad cannot be added.

Reinforcement and adhesive tape should be designed as strips as much as possible, and should not be designed as single pieces (see example / L29654A). The labor cost of single pieces is high.

If the electromagnetic film can achieve the desired effect without pasting, it is recommended not to paste it (it must undergo rigorous testing) (see example / LD9742C / L4E236A).

Product appearance: The product appearance should be designed as standardized as possible, which can save a lot of costs (see example / LDC964A / D25053A).

In terms of material selection, the material that meets the FPC can be selected in combination with the actual application of FPC. It is not necessary to choose the best material, as long as it can achieve the effect of actual application. This will not cause additional waste.

Reinforcement and adhesive tape should be designed as standardized rectangles or squares as much as possible to reduce mold costs.

If the hierarchical structure can be made into four layers, it is not necessary to make it into five layers (if the function remains unchanged). This can greatly reduce costs.

The single piece area of the board can be reduced as much as possible, and the utilization rate of the plate can be increased as much as possible. The utilization rate will be improved, and the unit price will naturally be lower.

It is ideal to make the hole of FPC larger (0.25-0.3). The quality of copper plating is guaranteed with large holes, and there will not be too many problems, and the yield rate can be improved. The cost of drilling can be reduced with large holes, which can reduce the overall unit price of FPC.

The circuit should be as thick as possible (if allowed), and the yield rate of FPC will naturally be higher with thicker circuits. The overall unit price of FPC will also be reduced.

Try to reduce the number of holes without direct connection wires (if allowed). With fewer holes, the cost of drilling is lower. The overall unit price of FPC will also be reduced. (LDD340)

If the text can be made on one side, try to make it on one side or not, and etch it directly on the copper foil, which can reduce the cost of the text screen.

After analyzing the process flow of factories around the industry, the production process of each factory is basically the same, but in order to improve the performance of dynamic FPC, each company mainly replaces copper + thin copper with black holes in the above process, and replaces chemical degumming with plasma to make precise fine lines; as well as breakthroughs in material selection and equipment performance and process.

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now

|

Dimensions: (mm) |

|

|

Quantity: (pcs) |

|

|

Layers: 2 |

Thickness: 1.6 mm |

|

|

|