Support Team

Feedback:

support@nextpcb.comIn the development of electronic industry, choosing the right PCB not only impacts performance but also plays a crucial role in cost control. If you're looking for the cheapest PCB manufacturers in China, you've come to the right place! In this article, we'll introduce you to the reliable cheapest PCB manufacturers in china without compromising on quality, helping you achieve the best results for your project within budget.

Chinese PCB manufacturers typically offer more competitive prices than those in other countries or areas. This is largely due to China's large-scale production capabilities, mature supply chain, and lower labor costs. Choosing a Chinese manufacturer can significantly reduce production costs, making it an ideal choice for startups or small to medium-sized companies with limited budgets.

Driven by government policy support, infrastructure investment, labor advantages, and support for technological innovation, china boasts world-leading electronics manufacturing infrastructure, and many PCB manufacturers offer a wide range of PCB types, from single-layer to multi-layer PCBs, and even HDI (High-Density Interconnect) PCBs. Whether you need small-batch PCB prototypes or large-scale PCB production, Chinese manufacturers can deliver efficient and high-quality services.

Many Chinese PCB manufacturers offer fast PCB prototyping and fast delivery times, with some even capable of completing samples within 24 hours. This is a huge advantage for engineers and development teams who need to quickly validate designs, make adjustments, and test their products.

Many Chinese manufacturers support flexible order quantities, ranging from small batches to large-scale production, to meet different stages of development. For startups and R&D teams, small-batch orders can reduce financial pressure while still ensuring quality control.

Despite the lower prices, many Chinese PCB manufacturers adhere to high-quality standards, passing international certifications such as ISO, UL, IATF16949 and others. This ensures that clients not only benefit from lower costs but also receive PCBs that meet global quality and safety standards.

With the advancement of technology, China's PCB manufacturers are also at the forefront of technological innovation, capable of providing increasingly complex circuit board designs, such as flexible circuit boards (FPC) and HDI boards. Many Chinese manufacturers also offer customization services, assisting clients in designing and optimizing circuit boards to meet specific functional requirements.

Many Chinese PCB manufacturers provide full after-sales support, including design checks, testing, and engineering consulting, helping clients resolve any issues during the design and production stages. Many also offer online platforms where clients can easily track order status and progress.

China is a major hub for global electronics manufacturing, boasting a well-established supply chain system. Manufacturers can not only provide PCBs but also collaborate closely with other electronic component suppliers to offer one-stop solutions, helping clients complete the entire product development process more efficiently.

While price is naturally a key factor when searching for the cheapest PCB manufacturers, quality should never be overlooked. Low prices do not always equate to low quality. In the PCB industry, quality is often closely related to the manufacturing process, material selection, equipment, and the manufacturer's experience.

Different PCB manufacturers have different MOQ requirements. Some allow very low MOQ, even accepting single-piece samples, while others may have higher MOQ. Pay attention to this when selecting the right manufacturer.

Many PCB manufacturers offer volume PCB order discounts, which can significantly reduce costs for large-scale production projects. These discounts are a key advantage, especially for projects requiring mass production.

In addition to basic PCB production, many PCB manufacturers offer additional services, which can impact the overall cost and lead time of your project. Understanding these services can help you assess the overall value.

In summary, when looking for the cheapest PCB manufacturers in China, price is important, but it is crucial to consider factors like quality, services, and volume discounts. Understanding the manufacturer's MOQ, volume order price, and additional services will help you lower costs while ensuring quality and increasing overall project efficiency.

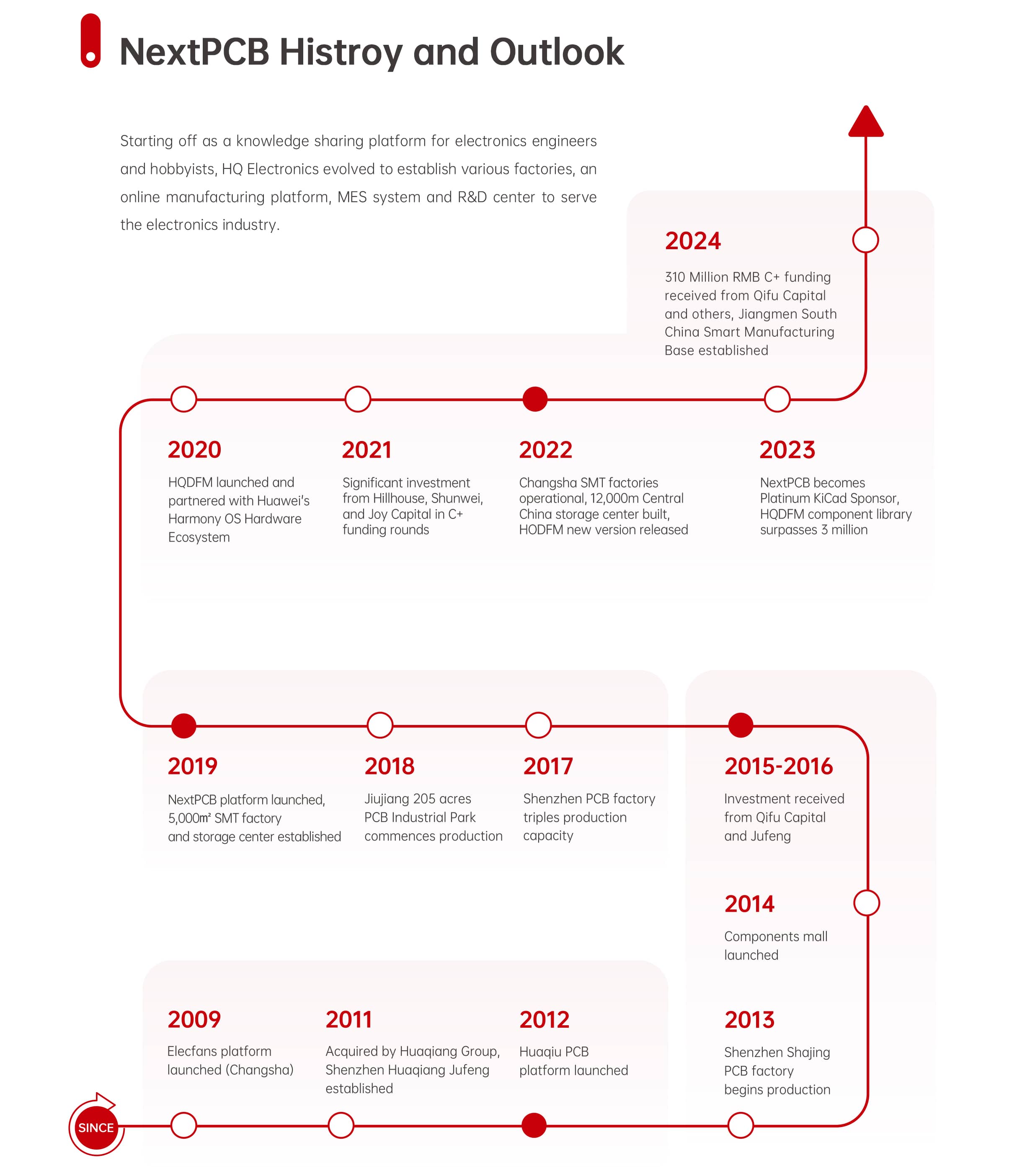

NextPCB provides the Cheapst PCB manufacturing starting at just $0.1 for 10 pieces. Founded in 2009, the company specializes in PCB prototyping, manufacturing, assembly services, and component distribution. It provides comprehensive solutions for global customers, from prototype to mass production. NextPCB offers a wide variety of PCB types, including single-sided, double-sided, multi-layer, flexible, rgid, rgid-flex and HDI boards.

Here are some of NextPCB's features and advantages:

NextPCB offers the cheapest PCB prototyping services (with prices starting at just $0.1 for 10 pieces), mainly to attract more clients, especially those in the early stages of electronic product development. Prototyping services are often an essential part of the product development process, as design verification, prototyping, and testing need to be done on real PCBs. Here are a few reasons why NextPCB offers low-cost prototyping services:

For startups or individual engineers, budgets are often tight when developing new products. By offering low-cost prototyping services, NextPCB helps these clients lower development costs, thereby attracting more potential customers. This also helps build brand loyalty, and once these clients' projects enter mass production, they may continue working with NextPCB.

Prototyping is key for design teams to validate functionality and fix any issues. During the early stages, engineers might make multiple modifications to circuit designs, so low-cost prototyping helps reduce the costs associated with these iterations. NextPCB's cheapest prototyping service allows customers to iterate and test their designs multiple times, ensuring the final design is optimized.

Offering cheapest PCB prototyping is a marketing strategy designed to lower the entry barriers for customers, helping NextPCB get more orders and valuable feedback. Satisfied customers may refer others, and as projects transition from small batches to mass production, NextPCB can accumulate loyal clients.

The PCB industry is highly competitive, with many manufacturers offering prototyping services. By providing low-cost yet high-quality prototyping services, NextPCB stands out in the market, attracting more customers compared to competitors.

Although low-cost prototyping may not yield large immediate profits, by securing long-term cooperation and mass production orders, NextPCB can gain more revenue from long-term contracts and large-scale production. In other words, low-cost prototyping acts as a customer acquisition strategy, leading to profitable mass production and ongoing collaboration.

As NextPCB gains more prototyping orders, they are able to lower production costs through more efficient workflows and optimized automation systems, allowing them to maintain competitive prices without sacrificing quality.

In conclusion, offering the cheapest PCB prototyping is a strategic move by NextPCB to reduce customers' entry costs, expand market share, and build a stable client base over the long term. Even though NextPCB provides the cheapest PCBs, they never compromise on quality. In the fiercely competitive PCB industry, they are committed to delivering high-reliability, low-cost PCB manufacturing and assembly services. Their facilities are certified to IATF16949, ISO13485, ISO9001, and ISO14001 standards, ensuring the highest levels of quality, safety, and environmental compliance. They also comply with UL, RoHS, and REACH regulations, and provide free DFM, DFA analysis, and functional testing to ensure the highest product quality and reliability.

PCB from $0.1/10pcsView NextPCB CatalogView NextPCB Certificates

NextPCB Exclusive Offers to Support Your Projects and Growth in 2025

NextPCB Free PCB Prototype, Free Shipping

Get Early Access to Raspberry Pi RP2350 with NextPCB

Jumpstart Innovation with RP2040 and Free PCBA Prototypes

Save $200 on Professional Turnkey PCB Assembly from HQ NextPCB

FREE Functional Testing for your Prototype PCBA with HQ NextPCB (blog)

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now

|

Dimensions: (mm) |

|

|

Quantity: (pcs) |

|

|

Layers: 2 |

Thickness: 1.6 mm |

|

|

|