Support Team

Feedback:

support@nextpcb.comMOSFETs, or metal oxide semiconductor field effect transistors, are one of the most versatile and powerful electronic components available. They can be used in a wide variety of applications, from switching power supplies to amplifiers. However, like any electronic component, MOSFETs can fail. If you suspect that a MOSFET in your circuit is bad, it is important to be able to test it quickly and easily.

This article will provide you with a comprehensive guide to testing MOSFETs. We will cover the following topics:

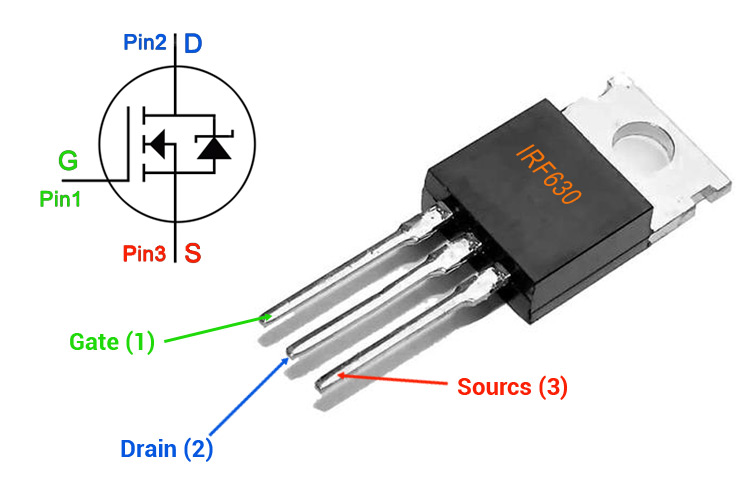

A metal–oxide–semiconductor field-effect transistor (MOSFET, MOS-FET, or MOSFET) is a type of field-effect transistor (FET), most commonly fabricated by the controlled oxidation of silicon. It has an insulated gate, the voltage of which determines the conductivity of the device. This ability to change conductivity with the amount of applied voltage can be used for amplifying or switching electronic signals. A metal-insulator-semiconductor field-effect transistor (MISFET) is a term almost synonymous with MOSFET. Another synonym is IGFET for the insulated-gate field-effect transistor.

MOSFETs are available in both n-channel and p-channel configurations. In an n-channel MOSFET, the majority of carriers are electrons, while in a p-channel MOSFET, they are holes. MOSFETs also have different voltage ratings, current ratings, and on-resistance ratings, which make them suitable for various applications.

These are commonly applicable for switching applications, as they can be rapidly turned on and off. MOSFETs are widely used in many different applications due to their ability to amplify signals with very little distortion and handle high voltages and currents without a great deal of power loss. To ensure the proper functioning of the circuit, it is essential to test these components. This is possible to achieve through in-circuit or out-of-circuit testing, as well as the use of advanced test equipment.

MOSFETs necessitate the utilization of special instruments and tools to examine them. A few examples of frequently used equipment and apparatus include:

For reliable and precise results, it is critical to use the right equipment and tools when assessing MOSFETs.

This easy-to-follow guide will lead you through the process:

Depending on the specific application, people can test MOSFETs in various ways. When constrained by circuit board connection, an in-circuit test is necessary to detect any potential faults that may exist – providing engineers with valuable insight into device performance. Engineers often prefer this method when the fault relates to the circuit itself or when the MOSFET is not easy to remove.

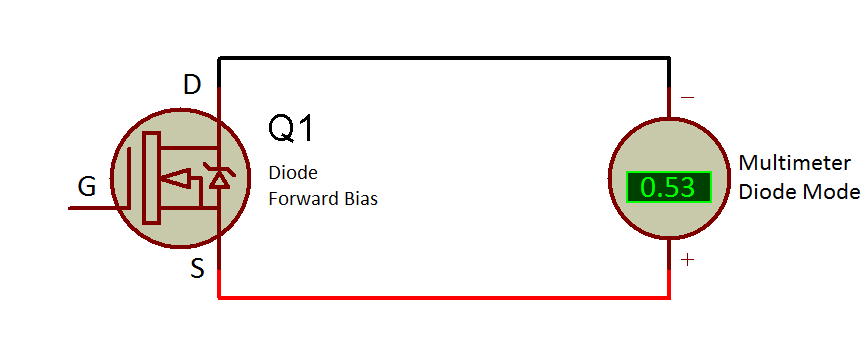

People can do in-circuit testing using a multimeter or MOSFET tester and can include tests such as measuring the threshold voltage, drain-source resistance, and gate leakage current.

If other components are affecting the measurements, in-circuit testing may not provide accurate results.

By eliminating the MOSFET from its circuit board and testing it independently, we can achieve more reliable results through out-of-circuit testing. Rephrased: Out-of-circuit testing allows for more reliable results because it eliminates the risk of other components connected to the MOSFET affecting measurements.

Out-of-circuit testing can be done using a MOSFET tester and can include tests such as measuring the threshold voltage, drain-source resistance, and gate leakage current. To ensure a reliable and safe operation, out-of-circuit testing should also involve visually examining the component for any indications of physical damage or overheating.

Ultimately, both in-circuit and out-of-circuit testing have their own distinct benefits as well as drawbacks. In-circuit testing is faster and more convenient but may not provide accurate results if there are other components affecting the measurements. Rephrased: Achieving more precise results through out-of-circuit testing involves the removal of the MOSFET from the circuit board, which is a time-consuming process that may require specialized tools. The choice of testing method depends on the specific application and the nature of the fault.

There are several common faults that can occur, including:

Identifying faults can be challenging, but by following proper testing procedures and taking appropriate precautions, faults can be identified and resolved.

When troubleshooting MOSFET circuits, it is important to follow a systematic approach to identify the cause of the fault. Here are some steps to follow when troubleshooting circuits:

Diagnosing and repairing MOSFET circuits can be an intimidating prospect, but with the right approach, it's possible.

In conclusion, testing and troubleshooting MOSFETs require careful attention and adherence to proper procedures to ensure accurate results and avoid damage to the circuit or other components. By using the appropriate tools and equipment, following established testing procedures, and taking appropriate safety precautions, it is possible to identify and resolve faults efficiently.

When diagnosing and testing MOSFET circuits, it is essential to use effective procedures that consider the factors influencing performance. Careful consideration should be given to in-circuit versus out-of-circuit tests as well as common faults while consulting with corresponding datasheets for detailed specifications and guidelines. Recording measurements taken during setup helps engineers save time troubleshooting future issues while avoiding costly repairs of operational systems. By following best practices when conducting these tests, technicians can ensure reliable outputs from their circuitry projects!

Don't be intimidated by a technical issue, get expert help from an engineer or technician and skillfully resolve it. They can ensure that all testing and procedures are performed appropriately for optimal results. With careful attention and proper procedures, MOSFET testing and troubleshooting can be an effective way to maintain the reliability and performance of electronic circuits.

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now

|

Dimensions: (mm) |

|

|

Quantity: (pcs) |

|

|

Layers: 2 |

Thickness: 1.6 mm |

|

|

|