Support Team

Feedback:

support@nextpcb.comPrinted Circuit Boards (PCBs) form the backbone of all major electronics - essential for their internal function. Among various PCB materials, Teflon, the brand name for Polytetrafluoroethylene (PTFE), stands out for its superior properties. Teflon PCBs, known for their high frequency and heat resistance, have been transforming the electronics industry since their inception.

Teflon was invented by Roy Plunkett in 1938 and was later incorporated into PCB technology due to its exceptional dielectric properties. Over the years, Teflon PCBs have been increasingly used in complex and high-frequency electronics, proving crucial in the evolution of cutting-edge technology. From their initial application in military technology during the mid-20th century to their current use in advanced communication systems, Teflon PCBs have revolutionized the way we perceive and develop electronics.

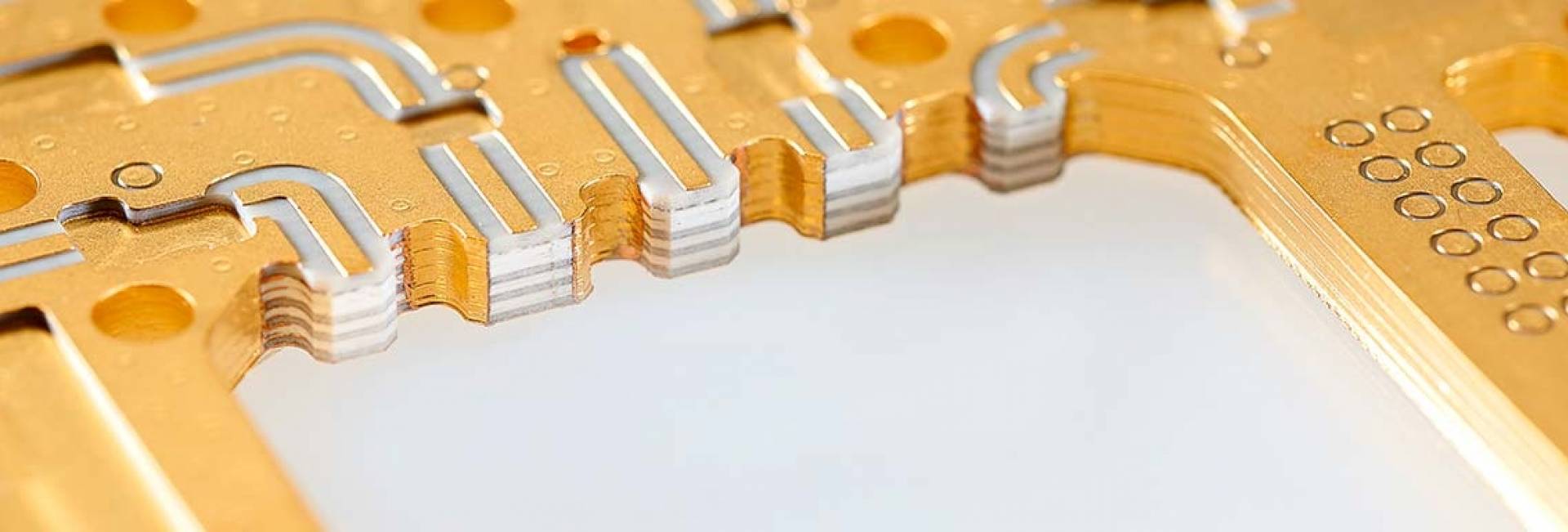

A Teflon PCB, also known as a PTFE PCB, is a unique type of high-frequency printed circuit board that utilizes Polytetrafluoroethylene, better known as Teflon, a brand name by Dupont Corporation for its PTFE materials. This type of PCB is specifically designed to transmit signals at frequencies of 5GHz and above, making it an optimal choice for microwave and RF applications. The term "Teflon PCB" has become a common vernacular due to the popularity and widespread recognition of Dupont's brand.

In this article, you will get an insight into Teflon PCBs - what PTFE laminates are there to choose from, specifications of common Teflon PCBs, benefits and applications of Teflon PCBs, Teflon PCB manufacturing, etc.

A PCB made from Teflon exhibits exceptional mechanical, thermal, and electrical characteristics. It is particularly favored in scenarios that require superior frequency and temperature endurance. Here are some defining attributes of this type of printed circuit board:

Impressive Low-Temperature Durability: Teflon PCBs are extraordinarily resilient even in extreme cold, maintaining mechanical toughness and a 5% elongation at temperatures as low as -196 degrees Celsius.

Superb Resistance to Chemicals: Teflon PCBs are highly resistant to a wide array of chemicals, oils, and greases. Their intrinsic properties remain unaltered even when exposed to corrosive chemical environments.

Weather-Resilient: Teflon PCBs are celebrated for their ability to endure diverse and harsh weather conditions, underpinning their reliability and longevity.

Low Energy Dissipation: With a minimal dissipation factor, Teflon PCBs offer superior insulation properties, making them the preferred choice for high-precision and high-performance electronic systems like radar and radio frequency devices.

Superior Thermal Stability: Teflon PCBs can perform optimally even in environments with high temperatures, underscoring their versatility in heat-generating applications.

Non-reactive Nature: The robust bonds between the carbon and fluorine atoms in PTFE give Teflon PCBs their non-adhesive and non-stick nature, ensuring their unreactivity.

Minimal Water Absorption: Teflon PCBs are virtually impervious to moisture due to their low water absorption rate, making them suitable for operations in high-humidity environments.

Remarkable Electrical Qualities: Teflon PCBs are characterized by their low dielectric loss and consistent dielectric constant across an extensive frequency range. This, along with their high volume resistivity and breakdown voltage, makes them particularly effective in RF and microwave applications.

Here we list the specifications of the commonly used Teflon PCBs, including Rogers RO3003, RO3035, RO3006, RO3010, RT5870, RT5880, RT6002, RT6006, RT6010.2LM.

| Property | Typical Value | Direction | Unit | Condition | Test Method | |||

|---|---|---|---|---|---|---|---|---|

| RO3003 | RO3035 | RO3006 | RO3010 | |||||

| Dielectric Constant, ϵr Process | 3.00±0.04 | 3.00±0.05 | 6.15±0.15 | 10.2±0.30 | Z | - | 10 GHz 23℃ | IPC-TM-650 2.5.5.5 Clamped Stripline |

| Dielectric Constant, ϵr Design | 3.00 | 3.60 | 6.50 | 11.20 | Z | - | 8 GHz - 40 GHz | Differential Phase Length Method |

| Dissipation Factor, tan δ | 0.0010 | 0.0015 | 0.0020 | 0.0022 | Z | - | 10 GHz 23℃ | IPC-TM-650 2.5.5.5 |

| Thermal Coefficient of ϵr | -3 | -45 | -262 | -395 | Z | ppm/℃ | 10 GHz -50 to 150℃ | IPC-TM-650 2.5.5.5 |

| Dimensional Stability | -0.06 0.07 |

-0.11 0.11 |

-0.27 -0.15 |

-0.35 -0.31 |

X Y |

mm/m | COND A | IPC TM-650 2.2.4 |

| Volume Resistivity | 107 | 107 | 105 | 105 | MΩ·cm | COND A | IPC 2.5.17.1 | |

| Surface Resistivity | 107 | 107 | 105 | 105 | MΩ | COND A | IPC 2.5.17.1 | |

| Tensile Modulus | 930 823 |

1025 1006 |

1498 1293 |

1902 1934 |

X Y |

MPa | 23℃ | ASTM D638 |

| Moisture Absorption | 0.04 | 0.04 | 0.02 | 0.05 | - | % | D48/50 | IPC-TM-650 2.6.2.1 |

| Specific Heat | 0.9 | 0.86 | 0.8 | J/g/K | Calculated | |||

| Thermal Conductivity | 0.50 | 0.50 | 0.79 | 0.95 | - | W/m/K | 50℃ | ASTMD5470 |

| Coefficient of Thermal Expansion (-55 to 288℃) | 17 16 25 |

17 17 24 |

17 17 24 |

13 11 16 |

X Y Z |

ppm/℃ | 23℃/50% RH | IPC-TM-650 2.4.41 |

| Td | 500 | 500 | 500 | 500 | ℃ TGA | ASTM D3850 | ||

| Density | 2.1 | 2.1 | 2.6 | 2.8 | gm/cm3 | 23℃ | ASTM D792 | |

| Copper Peel Stength | 12.7 | 10.2 | 7.1 | 9.4 | lb/in | 1 oz. EDC After Solder Float | IPC-TM-2.4.8 | |

| Flammability | V-0 | V-0 | V-0 | V-0 | UL 94 | |||

| Lead Free Process Compatible | Yes | Yes | Yes | Yes | ||||

| Property | Typical Value | Direction | Unit | Condition | Test Method | |||

|---|---|---|---|---|---|---|---|---|

| RT/duroid 5870 | RT/duroid 5880 | |||||||

| Dielectric Constant, ϵr Process | 2.33 2.33±0.02 spec. |

2.20 |

Z Z |

N/A | C24/23/50 C24/23/50 |

1 MHz IPC-TM-650 2.5.5.3 10 GHz IPC-TM 2.5.5.5 |

||

| Dielectric Constant, ϵr Design | 2.33 | 2.20 | Z | N/A | 8 GHz - 40 GHz | Differential Phase Length Method | ||

| Dissipation Factor, tan δ | 0.0005 0.0012 |

0.0004 0.0009 |

Z Z |

v | C24/23/50 C24/23/50 |

1 MHz IPC-TM-650, 2.5.5.3 10 GHz IPC-TM-2.5.5.5 |

||

| Thermal Coefficient of ϵr | -115 | -125 | Z | ppm/℃ | -50 - 150℃ | IPC-TM-650, 2.5.5.5 | ||

| Volume Resistivity | 2 x 107 | 2 x 107 | v | Mohm cm | C96/35/90 | ASTM D257 | ||

| Surface Resistivity | 2 x 107 | 3 x 107 | Z | v | C96/35/90 | ASTM D257 | ||

| Specific Heat | 0.96 (0.23) | 0.96 (0.23) | N/A | v | N/A | Calculated | ||

| Tensile Modulus | Test at 23℃ | Test at 100℃ | Test at 23℃ | Test at 100℃ | N/A | MPa (kpsi) |

A | ASTM D638 |

| 1300 (189) | 490 (71) | 1070 (156) | 450 (65) | X | ||||

| 1280 (185) | 430 (63) | 860 (125) | 380 (55) | Y | ||||

| Ultimate Stress | 50 (7.3) | 34 (4.8) | 29 (4.2) | 20 (2.9) | X | |||

| 42 (6.1) | 34 (4.8) | 27 (3.9) | 18 (2.6) | Y | ||||

| Ultimate Strain | 9.8 | 8.7 | 6.0 | 7.2 | X | % | ||

| 9.8 | 8.6 | 4.9 | 5.8 | Y | ||||

| Compressive Modulus | 30 (4.4) | 23 (3.4) | 27 (3.9) | 22 (3.2) | X | MPa (kpsi) |

A | ASTM D695 |

| 37 (5.3) | 25 (3.7) | 29 (5.3) | 21 (3.1) | Y | ||||

| 54 (7.8) | 37 (5.3) | 52 (7.5) | 43 (6.3) | Z | ||||

| Ultimate Stress | 30 (4.4) | 23 (3.4) | 27 (3.9) | 22 (3.2) | X | |||

| 37 (5.3) | 25 (3.7) | 29 (5.3) | 21 (3.1) | Y | ||||

| 54 (7.8) | 37 (5.3) | 52 (7.5) | 43 (6.3) | Z | ||||

| Ultimate Strain | 4.0 | 4.3 | 8.5 | 8.4 | X | % | ||

| 3.3 | 3.3 | 7.7 | 7.8 | Y | ||||

| 8.7 | 8.5 | 12.5 | 17.6 | Z | ||||

| Moisture Absorption | 0.02 | 0.02 | N/A | % | .062" (1.6mm) D48/50 |

ASTM D570 | ||

| Thermal Conductivity | 0.22 | 0.20 | Z | W/m/K | 80℃ | ASTM C518 | ||

| Coefficient of Thermal Expansion | 22 28 173 |

31 48 237 |

X Y Z |

ppm/℃ | 0-100℃ | IPC-TM-650, 2.4.41 | ||

| Td | 500 | 500 | N/A | ℃ TGA | N/A | ASTM D3850 | ||

| Copper Peel | 27.2 (4.8) | 31.2 (5.5) | N/A | pli (N/mm) | 1 oz (35mm) EDC foil after solder float | IPC-TM-650 2.4.8 | ||

| Flammability | V-0 | V-0 | N/A | N/A | N/A | UL94 | ||

| Density | 2.2 | 2.2 | N/A | gm/cm3 | N/A | ASTM D792 | ||

| Lead-Free Process Compatible | Yes | Yes | N/A | N/A | N/A | N/A | ||

| Property | Typical Value | Direction | Unit | Condition | Test Method |

|---|---|---|---|---|---|

| RT/duroid 6002 | |||||

| Dielectric Constant, ϵr Process | 2.94±0.04 | Z | - | 10 GHz/23℃ | IPC-TM-650, 2.5.5.5 |

| Dielectric Constant, ϵr Design | 2.94 | 8 GHz-40GHz | Differential Phase Length Method | ||

| Dissipation Factor, tan δ | 0.0012 | Z | - | 10 GHz/23℃ | IPC-TM-650, 2.5.5.5 |

| Thermal Coefficient of ϵr | +12 | Z | ppm/℃ | 10 GHz 0-100℃ | IPC-TM-650, 2.5.5.5 |

| Volume Resistivity | 106 | Z | Mohm cm | A | ASTM D257 |

| Surface Resistivity | 107 | Z | Mohm | A | ASTM D257 |

| Tensile Modulus | 828 (120) | X,Y | MPa (kpsi) | 23℃ | ASTM D638 |

| Ultimate Stress | 6.9 (1.0) | X,Y | MPa (kpsi) | ||

| Ultimate Strain | 7.3 | X,Y | % | ||

| Compressive Modulus | 2482 (360) | Z | MPa (kpsi) | ASTM D638 | |

| Moisture Absorption | 0.02 | - | % | D48/50 | IPC-TM-650, 2.6.2.1 ASTM D570 |

| Thermal Conductivity | 0.60 | - | W/m/K | 80℃ | ASTM C518 |

| Coefficient of Thermal Expansion (-55 to 288 ℃) | 16 16 24 |

X Y Z |

ppm/℃ | 23℃/50% RH | IPC-TM-650 2.4.41 |

| Td | 500 | ℃ TGA | ASTM D3850 | ||

| Density | 2.1 | gm/cm3 | ASTM D792 | ||

| Specific Heat | 0.93 (0.22) | - | J/g/K (BTU/lb/℉) | - | Calculated |

| Copper Peel | 8.9 (1.6) | lbs/in (N/mm) | IPC-TM-650 2.4.8 | ||

| Flammability | V-O | UL94 | |||

| Lead-Free Process Compatible | Yes |

| Property | Typical Value | Direction | Unit | Condition | Test Method | |

|---|---|---|---|---|---|---|

| RT/duroid 6006 |

RT/duroid 6010.2LM |

|||||

| Dielectric Constant, ϵr Process | 6.15±0.15 | 10.2±0.25 | Z | 10 GHz 23℃ | IPC-TM-650 2.5.5.5 Clamped stripline | |

| Dielectric Constant, ϵr Design | 6.45 | 10.7 | Z | 8 GHz - 40 GHz | Differential Phase Length Method | |

| Dissipation Factor, tan δ | 0.0027 | 0.0023 | Z | 10 GHz/A | IPC-TM-650 2.5.5.5 | |

| Thermal Coefficient of ϵr | -410 | -425 | Z | ppm/℃ | -50 to 170℃ | IPC-TM-650 2.5.5.5 |

| Surface Resistivity | 7x107 | 5x106 | Mohm | A | IPC 2.5.17.1 | |

| Volume Resistivity | 2x107 | 5x105 | Mohm·cm | A | IPC 2.5.17.1 | |

| Tensile Properties | ASTM D638 (0.1/min.strain rate) |

|||||

| Young's Modulus | 627 (91) 512 (75) |

931 (135) 559 (81) |

X Y |

MPa (kpsi) | A | |

| Ultimate Stress | 20 (2.8) 17 (2.5) |

17 (2.4) 13 (1.9) |

X Y |

MPa (kpsi) | A | |

| Ultimate Strain | 12 to 13 4 to 6 |

9 to 15 7 to 14 |

X Y |

% | A | |

| Compressive Properties | ASTM D695 (0.05/min. strain rate) |

|||||

| Young's Modulus | 1069 (155) | 2144 (311) | Z | MPa (kpsi) | A | |

| Ultimate Stress | 54 (7.9) | 47 (6.9) | Z | MPa (kpsi) | A | |

| Ultimate Strain | 33 | 25 | Z | % | ||

| Flexural Modulus | 2634 (382) 1951 (283) |

4364 (633) 3751 (544) |

X | MPa (kpsi) | A | ASTM D790 |

| Ultimate Stress | 38 (5.5) | 36 (5.2) 32 (4.4) |

X Y |

MPa (kpsi) | A | |

| Deformation Under Load | 0.33 2.10 |

0.26 1.37 |

Z Z |

% | 24 hr/50℃/7MPa 24 hr/150℃/7MPa |

ASTM D261 |

| Moisture Absorption | 0.05 | 0.01 | % |

D48/50℃, 0.050" |

IPC-TM-650, 2.6.2.1 | |

| Density | 2.7 | 3.1 | g/cm3 | ASTM D792 | ||

| Thermal Conductivity | 0.49 | 0.86 | W/m/K | 80℃ | ASTM C518 | |

| Coefficient of Thermal Expansion | 47 34,117 |

24 24,47 |

X Y,Z |

ppm/℃ | 23℃/50% RH | IPC-TM-650 2.4.41 |

| Td | 500 | 500 | ℃ TGA | ASTM D3850 | ||

| Specific Heat | 0.97 (0.231) | 1.00 (0.239) | J/g/K (BTU/lb/℉) | |||

| Copper Peel | 14.3 (2.5) | 12.3 (2.1) | pli (N/mm) | after solder float | IPC-TM-650 2.4.8 | |

| Flammability Rating | V-0 | V-0 | UL94 | |||

| Lead-Free Process Compatible | Yes | Yes | ||||

In the realm of printed circuit boards (PCBs), material choice plays a critical role. The most commonly used materials include FR-4, Polyimide, and Teflon.

FR-4, the most prevalent PCB material, offers affordability and decent performance but falls short in high-frequency applications. Polyimide PCBs, while costlier and potentially affected by moisture, excel in heat resistance and flexibility.

Teflon PCBs, also known as PTFE PCBs, are recognized for superior high-frequency performance, excellent heat resistance, and dimensional stability, but at a higher cost.

The following table provides a comparative overview of the key properties of these PCB materials:

| PCB Material | High-Frequency Performance | Heat Resistance | Flexibility | Cost | Potential |

|---|---|---|---|---|---|

| FR-4 | Moderate | Good | Good | Low | Not ideal for high-frequency applications |

| Polyimide | Good | Excellent | Excellent | High | Can be affected by moisture |

| Teflon (PTFE) | Excellent | Excellent | Good | High | Higher cost |

Teflon also has unique properties that make it an excellent choice for many PCB applications. However, like all materials, it also has its limitations. Let's explore both the advantages and disadvantages of Teflon PCBs.

Excellent High-Frequency Performance: Teflon PCBs exhibit superior high-frequency performance due to the low dielectric constant and low signal loss of Teflon. This makes them ideal for use in applications such as antennas and RF circuits.

High-Temperature Resistance: Teflon can withstand high temperatures, making Teflon PCBs suitable for applications that generate significant heat.

Chemical Resistance: Teflon is highly resistant to many chemicals, contributing to the longevity and reliability of Teflon PCBs in harsh environments.

Low Moisture Absorption: Teflon's hydrophobic nature ensures that Teflon PCBs have low moisture absorption, further enhancing their performance and durability.

Cost: Teflon is more expensive than many other PCB materials, which can increase the cost of the final product. It may not be the most cost-effective choice for applications that don't require its unique properties.

Difficult to Process: Teflon PCBs can be more challenging to manufacture than other PCBs due to Teflon's high melt viscosity and non-adhesive nature. This can also contribute to higher production costs.

Mechanical Strength: While Teflon PCBs exhibit high heat and chemical resistance, they are not as mechanically robust as some other types of PCBs, which can limit their use in certain applications.

Teflon PCBs are an excellent choice for certain applications due to their unique properties. These include low dielectric constant and loss, high-frequency performance, and excellent thermal stability. These characteristics make Teflon PCBs particularly suitable for high-speed digital circuits, radio frequency (RF) circuits, microwave communication systems, and other high-frequency applications.

However, despite their advantages, Teflon PCBs may not be the best choice for every situation. Here are a few factors to consider when deciding whether to use a Teflon PCB or an alternative:

Cost: Teflon PCBs are typically more expensive than other types of PCBs. Therefore, for projects with tight budgets or low-performance requirements, other materials such as FR4 or aluminum may be a more cost-effective choice.

Manufacturability: Teflon is more difficult to work with than some other materials. It requires specialized equipment and processes, which can increase manufacturing time and costs. If rapid prototyping or ease of manufacture is a priority, other PCB materials might be more suitable.

Mechanical Stability: While Teflon PCBs are excellent for high-frequency applications, they may not provide the same level of mechanical stability as other materials. If the PCB will be subjected to significant mechanical stress, a more robust material may be required.

Due to their unique properties such as low dielectric constant and loss, high frequency performance, and excellent thermal stability, Teflon PCBs find their usage primarily in high-frequency fields.

Military-grade Teflon PCBs, such as Rogers RT5000 and RT600 series, are extensively used in:

Antenna systems: Teflon PCBs are ideal for high-frequency antennas due to their excellent signal integrity, enhancing the performance of both transmitting and receiving functions.

Communication systems: In military communication systems, the high frequency and thermal stability of Teflon PCBs ensure reliable and continuous communication in different operating conditions.

Commercial Teflon PCBs, such as Rogers RO3000 series, have a wide range of applications including:

Active safety systems: In automotive and other safety-critical applications, Teflon PCBs provide reliable performance in sensors and other active safety components due to their stable electrical properties.

Power amplifiers, handheld device cellular, and WiFi antennas: Teflon PCBs provide superior performance at high frequencies, making them a preferred choice for these applications.

Backhaul radios, telematics, and information systems: The durability and high-frequency performance of Teflon PCBs make them ideal for these critical communication applications.

Crafting Teflon circuit boards demands a high level of precision and attentiveness. Manufacturers specializing in Teflon PCBs recognize the distinct differences between Teflon and standard FR4 PCB materials. The key manufacturing steps involved in the production of Teflon boards are as follows:

Surface Preparation: The initial step involves readying the substrate's surface for layer formation, marking, and metallization. The selection of tools used in surface preparation is crucial. Manufacturers avoid using bristles, scrubbers, and composite brushes, which could potentially damage the delicate laminate. Instead, surface preparation involves sodium etchants or plasma gas recycling on the PTFE surface.

Copper Plating: Teflon, as a ceramic material with high dielectric properties, requires careful copper plating. Given PTFE materials' high Z-axis coefficient of thermal expansion, it's essential to use plated copper on through-hole walls, featuring high tensile strength to decrease the likelihood of pad lifts and barrel cracks.

Application of Solder Mask: It's crucial to apply the solder mask within 12 hours of etching the material. Manufacturers process the etched surface via a standard PTFE cycle, ensuring any residual moisture is eliminated by baking the PTFE laminates before solder mask application.

Drilling: Drilling is a specialized process for PTFE substrates covered with copper, employing a high chip load to eradicate fibers and PTFE tailing. PCB fabricators often favor ceramic-filled laminates due to their ease of drilling.

Handling and Storage: Given their softness, PTFE laminates require extra care to prevent tearing or gouging. It's recommended to store them at room temperature, away from sunlight, to prevent surface oxidation and contamination.

Lamination: Unlike other materials, Teflon substrates don't need oxide pretreatment. Manufacturers laminate PTFE and copper films under high pressures, without the need for bonding films or pre-pegs. Occasionally, Teflon PCB manufacturers might use bonding films or prepregs with a very low melting point to reduce processing temperatures. While PTFE-FR4 laminates are suitable for certain applications, they do require oxide pretreatment.

NextPCB, a premier PCB manufacturer, offers comprehensive Teflon PCB manufacturing services, catering to a broad spectrum of needs from experienced engineers to solution companies and research institutes. Orders range from prototypes to batch fabrication, with NextPCB's expert team leveraging advanced technology to minimize thermal expansion and contraction of PTFE-based high-frequency materials. Additionally, they provide one-on-one engineering support and aim to maximize cost-efficiency for clients.

Distinctively, NextPCB maintains an in-house stock of Teflon laminates and other high-frequency materials, ensuring a storage period of 45 days for optimum quality. This strategy enables immediate commencement of manufacturing upon receiving Teflon PCB orders, significantly reducing delivery time.

Teflon PCBs, with their unique properties, have made a significant impact in demanding fields like aerospace, telecommunications, and high-speed computing. However, their higher costs and manufacturing complexity necessitate careful evaluation before use. As we look towards the future, advancements in Teflon PCB manufacturing could lead to decreased costs and increased efficiency, making them an even more enticing option for a broader range of applications. Remember, the choice of PCB material can be a game-changer in the performance of an electronic device, so always make an informed decision based on your project's needs.

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now

|

Dimensions: (mm) |

|

|

Quantity: (pcs) |

|

|

Layers: 2 |

Thickness: 1.6 mm |

|

|

|