What's PCB Surface Finish

Printed circuit boards (PCBs) are an essential component of many electronic devices. PCB surface finish technology plays a critical role in the quality and reliability of these devices. A surface finish is a thin layer of metal applied to the copper pads and traces on a PCB to protect them from oxidation and other types of corrosion. In the manufacturing process of printed circuit boards (PCB), surface finish technology is a crucial step.

There are several types of surface finishes available, each with its own advantages and disadvantages. Some of the most common surface finishes include HASL (hot air solder leveling), ENIG (electroless nickel immersion gold), and OSP (organic solderability preservatives).

This article will provide a detailed introduction to the features and pros and cons of various PCB surface finish technologies, helping you choose the technology that best suits your project needs.

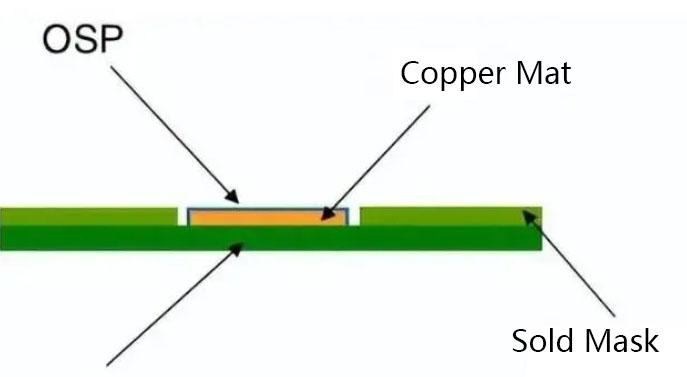

1.Organic Solderability Preservative (OSP)

OSP (Organic Solderable Preservative) or antirust agents are typically used in a conveyor belt process to coat exposed copper with a very thin protective layer of material that protects the copper surface from oxidation.

This film must be resistant to oxidation, thermal shock, moisture, etc. to protect the copper surface from rusting (oxidation or sulfidation, etc.) under normal conditions.

However, in subsequent high-temperature soldering, this protective film must be easily and quickly removed by the flux, so that the exposed clean copper surface can be immediately combined with the melted solder to form a strong solder joint in a very short period of time.

In other words, the OSP acts as a barrier between the copper and the air.

The general process of OSP is: degreasing -> micro-etching -> pickling -> pure water cleaning -> organic coating -> cleaning

OSP uses a water-based organic compound that selectively bonds to copper and provides an organometallic layer that protects the copper prior to soldering. It is also very environmentally friendly compared to other common lead-free finishes, which are more toxic or energy intensive

The advantages and disadvantages of OSP:

- Advantages: Environmentally friendly, low cost, lead-free, halogen-free

- Disadvantages: Short storage time, not suitable for multiple reflow soldering

2. Hot Air Solder Leveling (HASL)

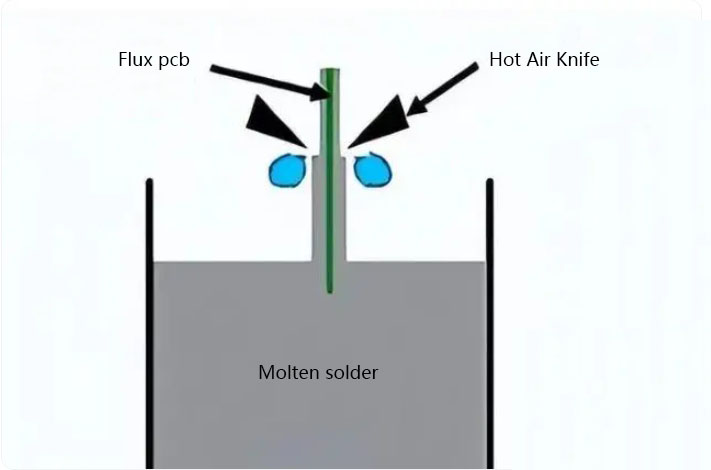

Hot Air Solder Leveling (HASL) is a traditional surface treatment method that immerses the PCB in molten tin and removes excess tin with a hot air knife to form a tin layer on the PCB surface. This method is cost-effective, but the uneven thickness of the tin layer may cause soldering issues.

The advantages and disadvantages of HASL:

- Advantages: Low cost, high reliability

- Disadvantages: Not suitable for soldering pins with fine gaps and components that are too small, Uneven tin layer thickness, may cause soldering issues.

According to the type of tin alloy used, HASL can be divided into two types: leaded HASL and lead-free HASL.

What is the difference between lead-free HASL and HASL?

Leaded HASL

Leaded HASL uses a tin alloy containing a certain proportion of lead for spraying. The addition of lead can improve the fluidity and soldering performance of the tin. In the manufacturing process, the addition of lead can reduce the temperature and time of the HASL process, thereby reducing damage to the PCB.

However, lead is a toxic substance that poses potential hazards to the environment and human health. Therefore, the use of leaded HASL has been gradually restricted and lead-free HASL has been promoted in some regions and industries.

Lead-free HASL

Lead-free HASL uses a tin alloy that does not contain lead for spraying to reduce environmental pollution and harm to human health. In the manufacturing process, lead-free HASL requires higher temperature and time than leaded HASL to achieve good soldering with electronic components.

As a manufacturer focusing on PCB Assembly service, NextPCB has rich experience and advanced technical capabilities in lead-free HASL, and can provide customers with high-quality, high-performance PCBA products.

3. Immersion Silver (ImAg)

Immersion Silver is a non-electrolytic chemical finish applied by immersing a copper PCB in a silver ion bath. It is ideal for boards with EMI shielding and is also used for domed contacts and lead bonding. The average surface thickness of silver is 5-18 micro inches.

Considering modern environmental issues such as RoHS and WEE, immersion silver is more environmentally friendly than HASL and ENIG. It is also popular because it costs less than ENIG.

Even when PCBs processed with immersion silver are exposed to high temperatures, humidity, and contamination, it still provides good electrical properties and maintains good solderability, even if it loses its luster.

Silver immersion is a displacement reaction that directly coats copper with a layer of pure silver.

Sometimes dip silver is used in combination with an OSP coating to prevent the silver from reacting with sulfides in the environment.

Common applications include flat surface requirements, which may include:

Membrane switches

EMI shielding

Aluminum wire bonding

Very fine traces

The advantages and disadvantages of immersion silver:

- Advantages: Good conductivity, good solderability

- Disadvantages: Short storage time, susceptible to contamination

4.Immersion tin (immersion tin) (ImSn)

Immersion tin (ImSn) is a metallic finish deposited by a chemical displacement reaction and applied directly to the base metal of a circuit board, i.e. copper.

ISn protects the underlying copper from oxidation during its expected shelf life. Since all solder is tin-based, the tin layer can match any type of solder.

The addition of organic additives to the tin dipping solution results in a granular structure of the tin layer, which overcomes the problems associated with tin whiskers and tin migration, while also providing good thermal stability and solderability.

The tin dipping process creates flat copper-tin intermetallic compounds, giving the dipped tin good solderability without the problems of flatness and intermetallic compound diffusion.

5.Chemical nickel-plated immersion gold(ENIG)VS Chemical nickel plating Chemical palladium immersion gold (ENEPIG)

1)ENIG (Electroless Nickel Immersion Gold) surface treatment has long been the best option for fine-pitch (flat) surfaces and lead-free requirements.

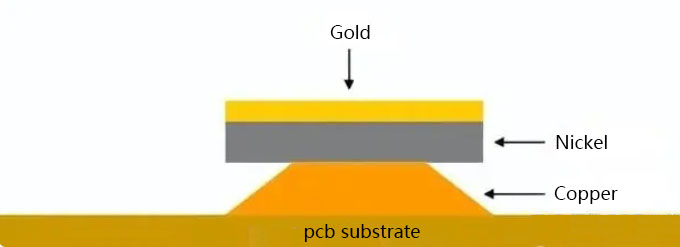

ENIG is a two-step process where a thin layer of gold is deposited over a thin layer of nickel. Nickel acts as a barrier to the copper and is the surface onto which components are actually soldered, while gold protects the nickel during storage.

The typical thickness of the nickel layer is 3-6 μm, while the gold layer is generally 0.05-0.1 μm.

Nickel forms a barrier layer between the solder and copper.

Gold's role is to prevent oxidation of the nickel during storage, thus extending shelf life, and the gold plating process also results in excellent surface flatness.

The ENIG processing flow is as follows: Cleaning -> Etching -> Catalyst -> Electroless Nickel Plating -> Immersion Gold Plating -> Residue Cleaning

Although this coating process has a long shelf life and is beneficial for plating through-holes, it is a complex and expensive process that cannot be reworked and is known to cause losses in signal RF circuits.

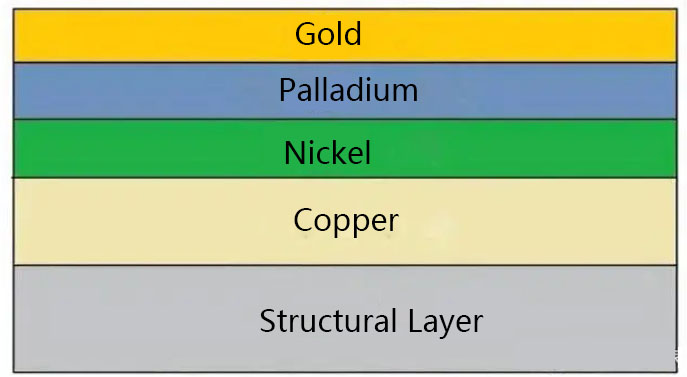

2)Chemical nickel plating Chemical palladium immersion gold (ENEPIG)

Chemically impregnated gold plated materials have a copper-nickel-palladium-gold layer structure that can be lead-bonded directly to the plating. The last gold layer is very thin, as in ENIG. The gold layer is soft, as in ENIG, so excessive mechanical damage or deep scratches may expose the palladium layer.

In contrast to ENIG, ENEPIG has an additional layer of palladium between the nickel and the gold, which further protects the nickel layer from corrosion and prevents the black matting that can occur in ENIG finishes.

Ni is deposited at a thickness of about 3 to 6 μm, palladium at about 0.1 to 0.5 μm, and gold at 0.02 to 0.1 μm.

The ENEPIG finish consists of four metal layers:

The difference between **ENEPIG** and **ENIG** lies in the addition of a palladium layer. Palladium helps protect the nickel layer from corrosion, which helps prevent the occurrence of "black pad." This is one of the significant advantages of ENEPIG over ENIG in terms of surface finish. The immersion gold layer on top of the palladium provides almost complete protection for the circuit board by safeguarding and preserving the underlying palladium.

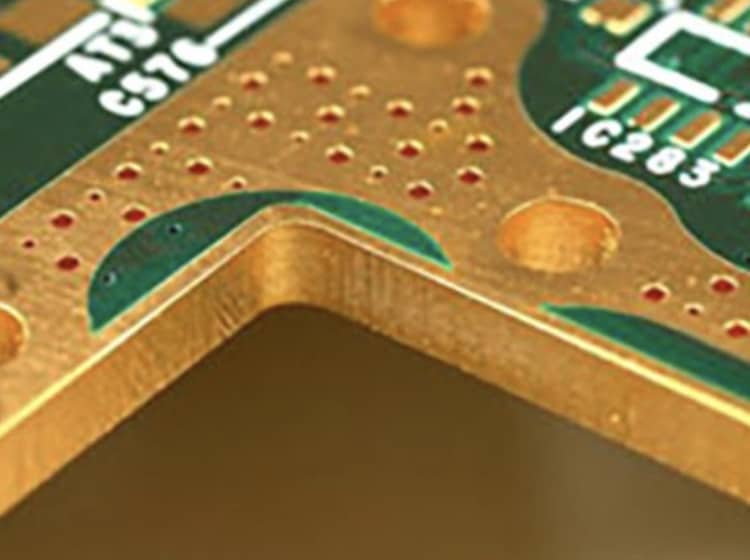

6. Electroplated Hard Gold (Hard Gold Plating)

Electroplated Hard Gold is a method of plating hard gold on the PCB surface, mainly used for high wear resistance and high-reliability applications such as connectors and switches. Electroplated hard gold has a higher cost but offers good wear resistance and conductivity.

The advantages and disadvantages of hard gold plating:

- Advantages: Good wear resistance, conductivity

- Disadvantages: Higher cost

How to choose PCB Surface Finish ?

PCB finish selection is the most important step in PCB manufacturing because it directly affects process yields, amount of rework, field failure rates, testability, scrap rates, and cost. To ensure high quality and performance of the final product, all important considerations for assembly must be taken into account in the surface finish selection.

1、 PCB Surface Finish - Pad Flatness

As mentioned earlier, certain surface finishes can result in uneven surfaces, which can affect performance, solderability and other factors. If flatness is an important factor, consider surface finishes with thin, uniform layers. In this case, suitable options include ENIG, ENEPIG, and OSP.

2. Solderability and Wettability

Solderability is always a key factor when working with PCBs, and specific finishes such as OSP and ENEPIG have been shown to hinder solderability, while other finishes such as HASL are well suited.

3. Gold or Aluminum Wire Bonding

If your PCB requires gold or aluminum wire bonding, it may be limited to ENIG and ENEPIG.

4. Storage Conditions

As mentioned earlier, some finishes (such as OSP) can make PCBs brittle when handled, while other finishes increase durability. Prior consideration should be given when considering storage and handling requirements, and surface treatments that make PCBs brittle should be used only when risk-free storage and handling requirements can be met.

5. Soldering cycle time

How many times does a PCB have to be soldered and reworked? Many finishes are ideal for rework. However, other methods such as immersion tin are not suitable for rework.

6, PCB Surface Finish - RoHS Compliance

RoHS compliance is critical when determining the surface finish to be used. Generally, all finishes that use lead are not RoHS compliant and should be avoided.

Based on the description of each surface finish above, a number of attributes are the most important elements to use as selection criteria. The table below shows the attributes that each surface finish does and does not have.

Depending on the specific requirements and characteristics of the PCB product, you can follow this table to select the perfect surface finish option.

To summarize, it is important to choose the best type for the type of surface finish option in order to accomplish numerous functions. Each type of surface finish has its own advantages and disadvantages. There are a number of engineering techniques that can be used to solve problems caused by the disadvantages of surface finishes. For example, there are solutions to the disadvantage of low OSP wetting power, such as changing the board solderability plating or wave soldering alloys, increasing top surface preheating, etc. The key is that all possible factors must be considered to obtain the desired performance.