Support Team

Feedback:

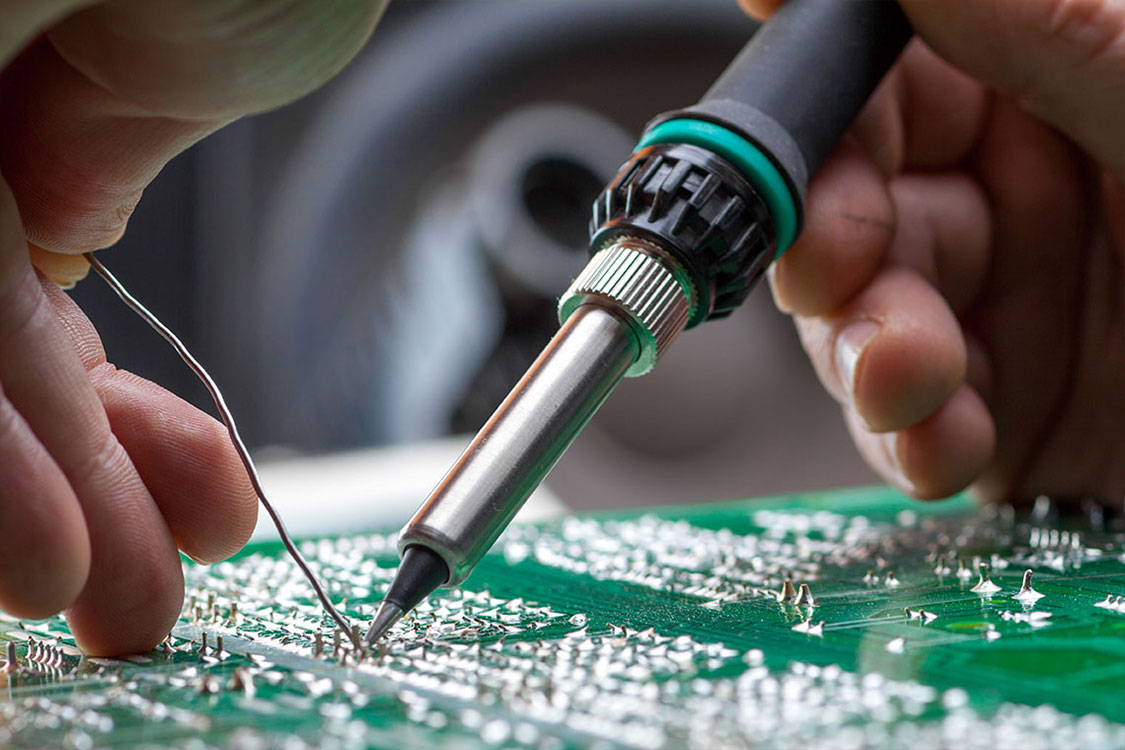

support@nextpcb.comSolder is a type of metal alloy that can be easily shaped and melted to form strong bonds between two objects. As such it is an alloy it has tin and leads as its components. On this day, we have two types of solder:

A leaded solder or soft solder has tin and lead as its main components. It has a lower melting point (183 °C or 361 °F) than lead-free solder which makes it preferred over lead-free solder as it has a lower thermal effect on the PCB and its components. Besides the lower thermal damage to the circuit board, leaded solder provides a smooth-appearing joint that is brighter than lead-free solder and causes fewer quality issues.

A lead-free solder was enforced use by the Waste Electrical and Electronic Equipment Directive and Restriction of Hazardous Substances Directive, in the year 2006 due to health and environmental concerns. Unlike leaded solder composition of lead-free solder can vary and consists of a mixture of different metals, such as tin, copper, silver, nickel, and zinc. However, tin with copper is the most commonly used combination. The melting point of lead-free solder may range from 50 to 200 °C or higher. Adequate wetting ability in lead-free solder calls for approximately 2% flux by mass.

To tackle different problems, PCB manufacturers and assemblers have tried and tested several types of metals with tin to form a suitable alloy. Some of the most common lead-free solder combinations are

Being precise leaded and lead-free solder is different in their formation levels which impacts their properties, behaviors, and features. In-depth, lead-free solder has a higher melting point ranging from 50 to 218 °C whereas leaded solder has a fixed melting point of 183 °C. Where a lower melting point makes it easy to work with leaded solder and causes less heat damage to the circuit board and components, over time, it may cause some technical issues due to its softness. Although lead-free solder has high corrosion resistance, it has lower wettability than leaded solder which makes its joint reliability uncertain.

Though leaded solder is cost-efficient, provides a smooth application, and causes less heat damage to the PCB it is extremely harmful to human health and the environment whereas lead-free solder is safer but more challenging to work with.

After the restrictions imposed on leaded solder concerning human health and the environment, the manufacturers somehow have to shift to lead-free solder for consumer electronics. Hence, analyzing the situation and developing a better understanding of the properties of leaded and lead-free solder and their difference is beneficial to select the best for your project.

Rusting is a major concern in printed circuit boards. It cuts the life of a circuit board and creates other technical issues like a short circuit. Hence it is a significant property to consider. Leaded solder is superior in several cases but when it comes to rusting, Lead-free solder exhibits higher corrosion resistance due to the lower passivation current density, lower corrosion current density after the breakdown of the passivation film, and a more stable passivation film on the surface compared to lead solder. Lead-free solder is a better choice for PCBs that have to operate under highly-humid areas.

The melting point of the solder is the greatest concern in PCB assembling as such it affects the PCB surface, tracks, and components. Unfortunately, unlike the leaded solder, the melting point of Lead-free solder is not fixed. It depends on its formulation and may range between 50 to 218 °C or higher. A higher melting point has these disadvantages:

Concerning the physical features, a leaded solder is softer than a lead-free solder. Hence lead-free solder may provide you with reliable joints but it may cause poor contact resistance performance due to its formulation. However, due to its high melting point lead-free solder witnesses fewer modifications and thermal effects and hence, consider reliable for SMD assembling over time. Further, the lead-free solder appears less shiner and smoother than the leaded solder.

Lead-free solder has lower wettability compared to leaded solder. It definitely raises questions on the joint reliability of lead-free solder.

| Parameters | Leaded Solder | Lead-free Solder | Units |

|---|---|---|---|

| Electrical Conductivity | 11.5 | 15.6 | IACS |

| Thermal Conductivity | 50 | 73 | (W / m) * 1 k * 1 s |

| Melting Point | 183 | 218 | °C |

| Resistivity | 15 | 11 | M ohm-cm |

| Surface Tension | 481 | 548 | mN/m |

| Fatigue Life | 3 | 1 | |

| TCE | 23.9 | 21.4 | micrometers/M/°C |

| Density | 8.5 | 7.44 | g/cm3 |

| Shear Strength | 23 | 27 | MPa |

Lead-free soldering is increasingly being embraced by environmentally-conscious companies due to the toxic nature of lead and its accumulation in the human body, even from small and prolonged exposures. Lead can easily enter the body through the skin, mouth, or nose and poses a greater risk to children and old persons. Although the paint and gasoline industries have successfully eliminated lead, solder is still one of the remaining products that use it. Workers in industries with high lead emissions are at greater risk of exposure and must take health concerns seriously.

However, taking these factors in mind the Waste Electrical and Electronic Equipment Directive and Restriction of Hazardous Substances Directive in the year 2006 restricted the use of lead in consumer electronics.

When it comes to the cost which is from the manufacturing point of view an efficient factor to consider, leaded solder is better as it is cost-efficient. Leaded and lead-free solder has a huge price difference due to their material cost. As we know lead-free solder combines other metals with tin (mostly copper) to form an alloy, whereas lead solder combines tin with lead which is ten times cheaper than tin and of course other metals, especially copper. Hence, it provides reasonable prices with quality.

Well, it is a quite controversial topic and people have their opinions depending on their requirements. It would be harsh to state directly that one is better than the other. Whatsoever, you can easily decide the suitable solder for your circuit board by analyzing your PCB requirements with both environmental and electrical aspects. If you're heading to use components with a lower dielectric constant, lead-free solder due to its high melting point may be vulnerable to components. In another scenario, if circuit boards have to operate under high corrosion environments lead-free solder is a better option s it exhibits higher corrosion resistance.

However, keeping in mind the restrictions and efforts of the United States and the European Union against leaded solder in consumer electronics it is likely better to avoid it.

The use of lead solder is often preferred over lead-free solder due to its ease of use, lower melting point, and ability to create reliable joints. However, if your government prohibits the use of lead or if the products will be sold in European countries that follow the RoHS directive, lead-free solder is the only option.

Lead-free solder is becoming increasingly popular as a replacement for traditional lead-based solder due to the health and environmental hazards associated with the latter. However, there are some drawbacks to using lead-free solder that must be considered. The disadvantages of lead-free solder include its high melting point, low wettability, tendency to form deposits, and the formation of tin whiskers and metal dendrites. Understanding these disadvantages is essential for anyone working with lead-free solder to ensure optimal performance and avoid potential problems.

Lead and Lead-free solder affect the quality and functioning of a printed circuit board. But PCB manufacturers with strictly controlled soldering parameters can somewhat control the quality and performance concerns. However, an appropriately designed layout and selection of components may help control unnecessary issues regarding soldering.

NextPCB tried its best to clear the concepts of leaded and lead-free solder. But still, it might be hard to conclude whether you should use lead or lead-free solder. So, well, the decision to use lead-free products for wave soldering or through-hole soldering is based on specific design parameters and the demands of the final assembled PCBs.

The board layout and component selection should be according to the solder type. It may help avoid several quality and performance issues. Otherwise, things could get a little messy.

In conclusion, soldering is an essential process in electronics to create enduring bonds between two objects. So, there are two types of solder lead solder and lead-free solder. With the evolution of technology and environmental and health concerns, lead-free solder has become an enforced choice over leaded solder. Although leaded solder provides a lower melting point, higher wettability, efficient cost, and smoother and brighter appearance, it is toxic and environmentally damaging. Lead-free solder is safe but challenging to work with, has a higher melting point, and is less reliable due to lower wettability. Selecting the right solder depends on the specific project and its requirements. Hence, it is crucial to understand the properties and differences between leaded and lead-free solder to choose the best fit for a project. Best Wishes from NextPCB!

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now

|

Dimensions: (mm) |

|

|

Quantity: (pcs) |

|

|

Layers: 2 |

Thickness: 1.6 mm |

|

|

|