Support Team

Feedback:

support@nextpcb.comIn the electronic interconnection industry, IPC stands for the global trade association. The primary goal of the IPC Class is to standardize the assembly, production process, and requirements of electronic components. In 1957, it was established under the Institute of Printed Circuits, which was later changed into the Institute for Interconnecting and Packaging Electronic Circuits.

The organizations publish the specifications and requirements regularly. The IPC standard is one of the most accepted protocols in the electronic industry. This IPC standard helps design and fabricate reliable, safe, high-quality PCB products.

The following article let readers know about the IPC Class and the differences between Class 2 and Class 3 PCB types.

IPC outlines the three major classes of PCBs. The classes depend on varying quality for broad applications. Every class explains the board types, including the numbers and defects for each class.

Class 1 requires the least performance and reliability since it allows most defects. Class 1 has the lowest quality circuit board. While class 3 is the high-quality standard and thus explains the strong requirements. Furthermore, these three classes are developed and governed by IPC under IPC-6011.

However, the significant difference between these three classes is the degree of inspection through which electronic assembly should go. Besides, the quality standards also define the Classes types. Other factors like cost and customer requirements also affect their performance.

IPC has categorized the three IPC Classes based on their quality and usability as Class 1, Class 2, and Class 3.

The Class 1 board is referees to as the general electronics board. They are low-quality boards with fewer requirements or electronic components.

Overall, they allow various defects as long as it doesn't affect the board's functionality. Thus, reliability is not a significant factor in these Class 1 boards.

They are used in products with short life spans. These products mainly include everyday products and consumer electronics.

Class 2 boards have higher reliability. Also, it has a higher life expectancy compared to Class 1 boards. They follow more specific standard compared to Class 1 but allows some defects also. The Class 2 products aren't exposed to extreme environmental conditions. It expects uninterrupted service but is not a critical factor as well. These boards are mostly implemented on laptops, tablets, cellular devices, etc.

Class 3 is the highest-quality board that must provide the continuous or required performance. As well as, this Class board goes through a high level of inspection and testing. Moreover, it follows high and precise standards of board design. Thus, it makes the board highly reliable. These boards include the devices like a life support system, automotive, military equipment, electronic monitoring system, etc.

Inspection

Boards in class 2 are more accessible to inspect than those in class 3. For example, a class 3 component's specific rules increase inspection time. The longer it takes, the higher the cost. Comparatively, the inspection process for class 2 boards is easy and fast.

Manufacturing

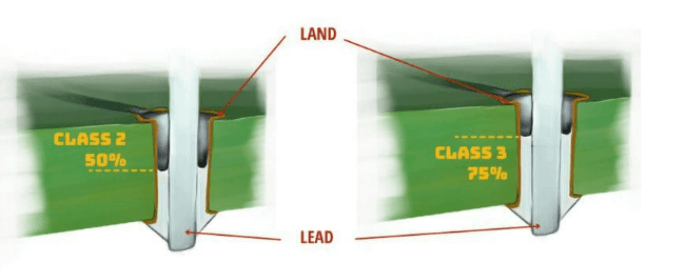

The manufacturing of class 3 boards takes a long time because some processes have to be slowed down to ensure perfection. Making a product takes time, leading to more expenses, making it very expensive. For example, when working with class 3 IPC standards, 75% of the solder fills thru-hole leads. In contrast, class 2 boards only require 50% solder.

Design

During the manufacture of class 3 boards, low tolerance for defects must be exercised, and strict specifications must be followed. In contrast, class 2 PCBs have a simpler design, and the rules are less stringent. It is easy to place and route all the components when using a class 2 product.

Inspection

Class 3 goes through a rigorous examination process concerning examination matters. Besides, makers will avoid expenses associated with bad reviews caused by defective products.

In order to identify deficiencies before complete creation, a careful assessment will provide the evidence right on time. As a result, high-performing hardware will help the organization gain the trust of its clients.

Manufacturing

Manufacturing processes in class 2 and class 3 differ significantly. Products in class 3 undergo more detailed manufacturing than those in class 2. Despite the moderate manufacturing process, the boards comprised of well-adjusted parts were excellent.

Design

During the class 3 process, close determinations are made to ensure a product meets the standards. Clients of this hardware, therefore, appreciate the confirmation that these items are of high quality and dependable. They follow a detailed, exact plan that meets all industry requirements.

The primary difference between Class 2 and Class 3 boards is found in plating thickness, placement of components, cleanliness, stringent standards and protocol requirements, annual ring requirements, manufacturing processes, etc.

The placement of components can be slightly off the pad during the assembly process of surface-mount components. This is also a visual defect, as it usually doesn't affect the mechanical and electrical performance system. This defect is considerable in Class 2. However, this can fail the inspection testing in Class 3 boards as the Class 3 board doesn't accept any defects or imperfections.

Besides, you can also find the difference in the amount of barrel fill. For Class 2, the amount to fill the barrel for a through hole is 50%. While Class 3 requires 75% of barrel fill. This is one of the delicate processes of getting the proper amount of fill or pastes into the smaller plate of through holes, so one must be very careful during this process.

| head1 | head2 | head3 |

|---|---|---|

| Surface-mount components | Can be slightly placed off the pad. (doesn’t affect the mechanical and electrical performance) |

|

| Barrel Fill | Through-hole leads 50% | Through-hole leads 75% |

Acceptable Solder Criteria for through-hole components

| Characteristics | Class 2 | Class 3 |

|---|---|---|

| Circular wetting of solder on lead and plated holes on the component side | 180 degrees | 270 degrees |

| Circular wetting of solder on lead and plated holes on the solder side | 270 degrees | 330 degrees |

| Plated Through Hole fill | 50% | 75% |

| Land Area covered with solder on the solder side | 75% | 75% |

Drill Breakdown

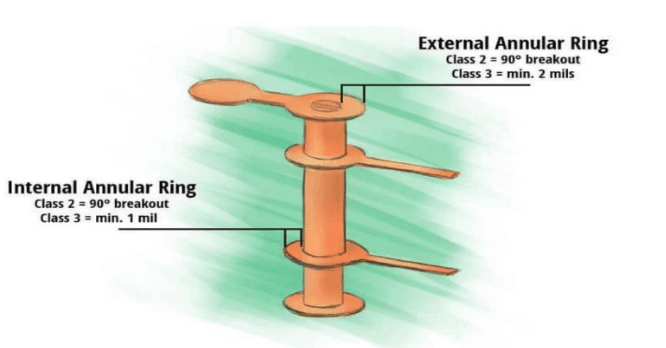

Drill breakdown is another factor that differentiates these two classes. There may be some breakdown in the annual rings. This defect is accepted in Class 2, while in Class 3, it is not acceptable.

Class 3 boards need to be highly reliable, and any defects or breakouts can fail the whole testing process. At the same time, Class 2 boards can accept the 90-degree break out of the hole, which would maintain the minimum lateral spacing.

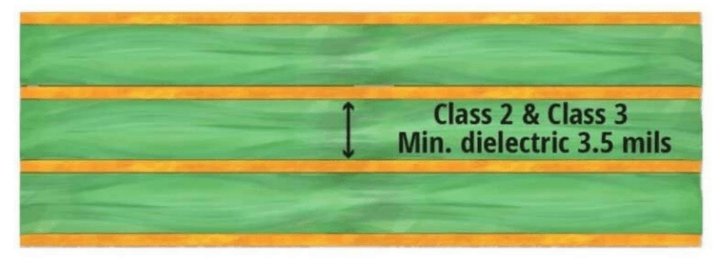

PCB Dielectric Requirement

The minimum dielectric requirement for Class 2 and Class 3 is 3.5 mils. Also, the users and suppliers can make a deal to use dielectric.

Cost

The cost of developing a Class 3 assembly product can add up to 20% of the product cost. Thus increasing the cost of Class 3 compared to Class 2 IPC. Besides, the higher concentration of through-hole increases the cost of the Class 3 board.

PCB-related standards are formulated by the IPC (Institute for Printed Circuits). This association was formerly known as the Institute for Printed Circuits. Despite the association's new name, Association Connecting Electronics Industries, the IPC name remains.

More than 4,000 industries are members of the IPC. They are responsible for designing PCBAs, including microelectronics, industrial equipment, medical services, computers, etc.

Therefore, IPC standards were implemented. Thus, PCB designs, manufacture, and assembly must follow standard practices in these electronics industries. Any manufacturer, defense officer, or electronics designer must comply with IPC. PCB design standards from IPC are among the most widely accepted worldwide.

IPC defects in PCBs include the following:

Annular ring

Copper pads surround drilled and finished holes in the annular ring. An IPC PCB defects common around the annular ring is annular ring defects. IPC annual ring is considered one of the primary concerns. However, for class 2, then there are some acceptable standards, like 90 degrees of fracture in the annual ring.

Solder joint

Solder Joint is another IPC defect in PCB. Not proper heat in the joint is the result of these solder joint defects. Sometimes, this also happens if the soldering iron is at a shallow temperature. These defects can affect the functionality of the PCB. Thus, the best soldering technique is the way of avoiding such problems. The acceptable standard separated for Class 2 and Class 3 is 180 and 270 degrees, respectively.

Component misalignment

It is one of the other IPC defects found in PCB. This takes palace when the components need to be positioned in the desired area. When components float on molten solder, this misalignment takes place. Thus, there are some guidelines for this component misalignment:

IPC creates the proper standards and protocols for manufacturing, designing, developing, and testing the PCB board. The proper way to integrate the IPC standards is by following the critical PCBA designs. Thus, IPC boards are widely used in electronics manufacturing. Many advanced electronics also use this IPC PCB.

Thus, Class types and the difference between them are crucial to understanding the selection of the right products. The above guidelines and tips can help you select the correct class PCB per your requirements.

Do not hesitate to contact us if you want to know more about PCB and PCB-related services.

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now

|

Dimensions: (mm) |

|

|

Quantity: (pcs) |

|

|

Layers: 2 |

Thickness: 1.6 mm |

|

|

|