Support Team

Feedback:

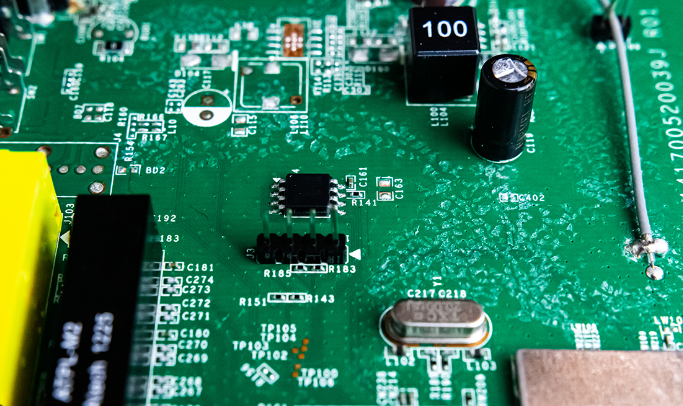

support@nextpcb.comA new Printed Circuit Board performs well, but in the long run, the performance deteriorates due to various factors, including the operating environment. There are some possible easy to protect the PCB from early deterioration. One way is to use a conformal coating that protects the PCB from moisture, temperature extremes, salt sprays, etc. Conformal coating allows designers to meet the demands of miniaturization and reliability by enabling higher voltage gradients and closer track spacing.

This article provides all the information about conformal coating, its types, the application process, and the removal process.

Conformal coating is a protective coating applied to printed circuit boards and other electronic components to protect them from moisture, dust, corrosion, and other environmental factors. It is a thin, protective layer that conforms to the shape of the component and seals it from its environment. Conformal coatings are typically applied as a liquid or spray and harden to form a protective barrier. They can come in a variety of materials, including acrylics, silicone, urethanes, and epoxies.

When the component is soldered onto a bare board during assembly, the exposed metal will be covered and protected by a surface finish like hot air solder leveling. Conformal coating can defend for a long time after assembly.

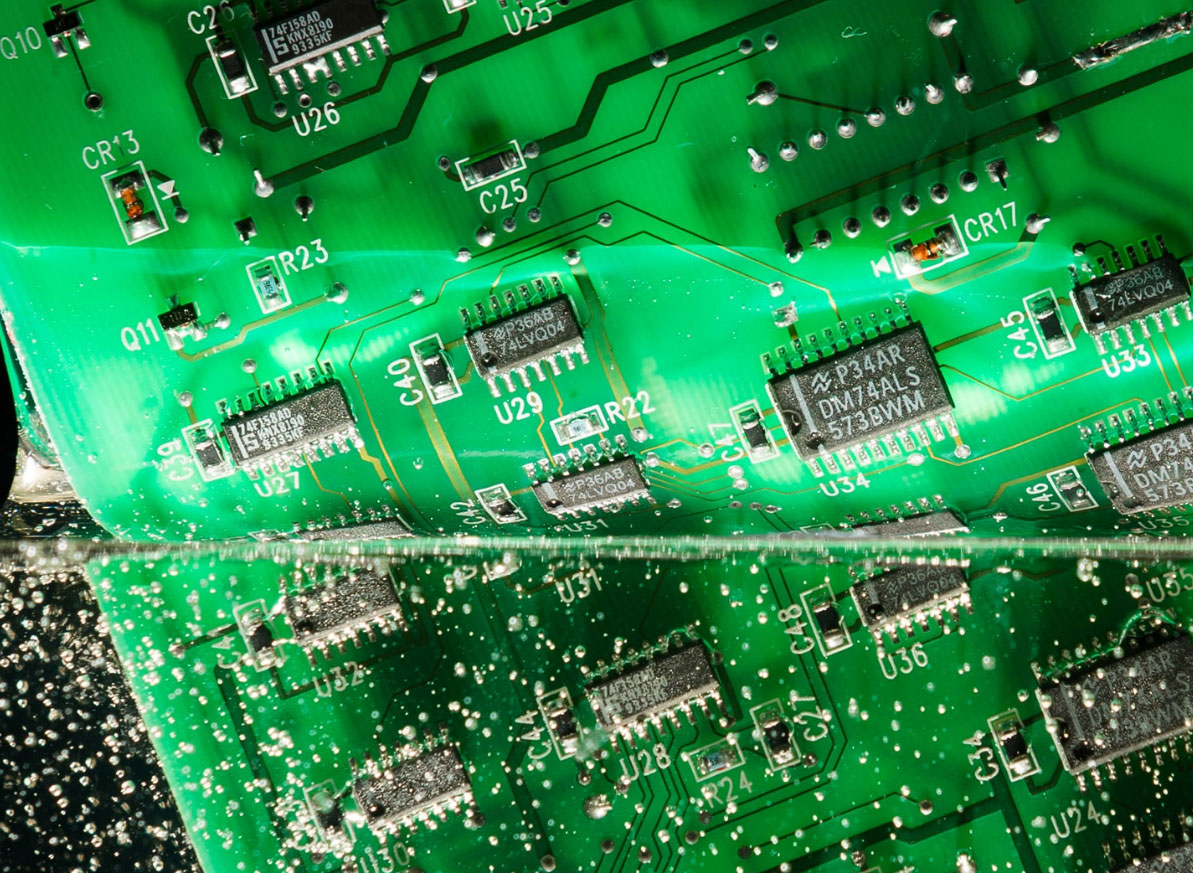

An operating environment can quickly deteriorate the performance of a newly manufactured printed circuit board due to external factors. Conformal coatings in various environments can prevent corrosion, mold growth, and electrical failures by protecting printed circuit boards from moisture, salt spray, chemicals, and extreme temperatures. In addition to providing protection, conformal coatings allow designers to meet the requirements of miniaturization and reliability by increasing voltage gradients and reducing track spacing.

Conformal coating is useful in aerospace, industry, green energy, and automotive applications. It is also applicable in domestic and mobile electronic applications that provide the best combination of high reliability and performance in many electronic devices. Besides, it is applicable in automotive, marine, aerospace, industrial, and military.

Each coating option has unique properties depending on the environment in which the PCB will be operating. Solvent-based materials have traditionally been used most widely because of their benefits, including:

Type of Conformal Coating includes:

It is relatively inexpensive to apply and repair AR coatings, and they provide good protection. Besides being dielectrically strong, they are also moisture and abrasion-resistant. A variety of solvents are readily available for removing acrylic coatings without agitation. This way, it is feasible and economical to rework and even perform field repairs. Therefore, acrylic coatings don't protect against solvent vapors and solvents and are unsuitable for aerospace applications. Some of the benefits of Acrylic Coating include the following:

It provides excellent protection over a wide temperature range. SR is highly flexible, chemically resistant, moisture resistant, and salt spray resistant. The rubbery nature of silicone conformal coatings makes them invulnerable to abrasion, but they are durable against vibrational stresses. Applications such as outdoor signage commonly use silicone coatings in humid environments. Depending on the type of solvent used, the soak time and the amount of agitation required can be challenging. The benefits of using SIlicone Resin include:

Evaporating water cure coating based on water. They are low-VOC options that use water to replace most of the solvents in the system. This improves operator safety while also significantly lowering solvent emissions. The advantage of using water-based coating includes the following:

Another type of hybrid coating is UV cure conformal coating. Different chemistry types are frequently used in this case to create a dual-cure system, avoiding issues with UV light shadowing during curing. UV cure coatings have the quickest curing times in seconds under UV light. This is extremely useful for high throughput applications, and any shadowed areas will eventually cure via the secondary cure system. They can be difficult to remove due to their highly cross-linked structure when cured, and in some cases, UV cure coatings are known to suffer reduced flexibility during thermal changes, so they must thoroughly test them. Some of the benefits of using UV cure include:

2K two-part coatings are hybrid technologies that combine the best qualities of encapsulation resins and conformal coatings. These materials provide some of the best protection while retaining the processability and cost-effectiveness of a conformal coating. The advantage of using 2K coatings include the following:

Epoxy resins (ER) are typically two-part compounds that produce a very hard coating. Unlike traditional conformal coatings, epoxy conformal coatings have excellent humidity resistance and are not generally permeable. They are also highly abrasion and chemical-resistant. They are typically difficult to remove once cured and are less flexible than the other materials. In contrast to conformal coatings, epoxy coatings are common in potting compounds, which cover the electronics in a solid and level layer of material.

While applying the Conformal Coating, you need to consider the following:

Some of the famous methods for applying conformal coating include:

It is usually used for small-volume production and is the best cost-effective solution. The manual spraying method uses an aerosol or handheld spray gun to apply the conformal coating. However, it is time-consuming and requires masking also. The consistency and quality are operator-dependent. Thus, the variations are common from board to board.

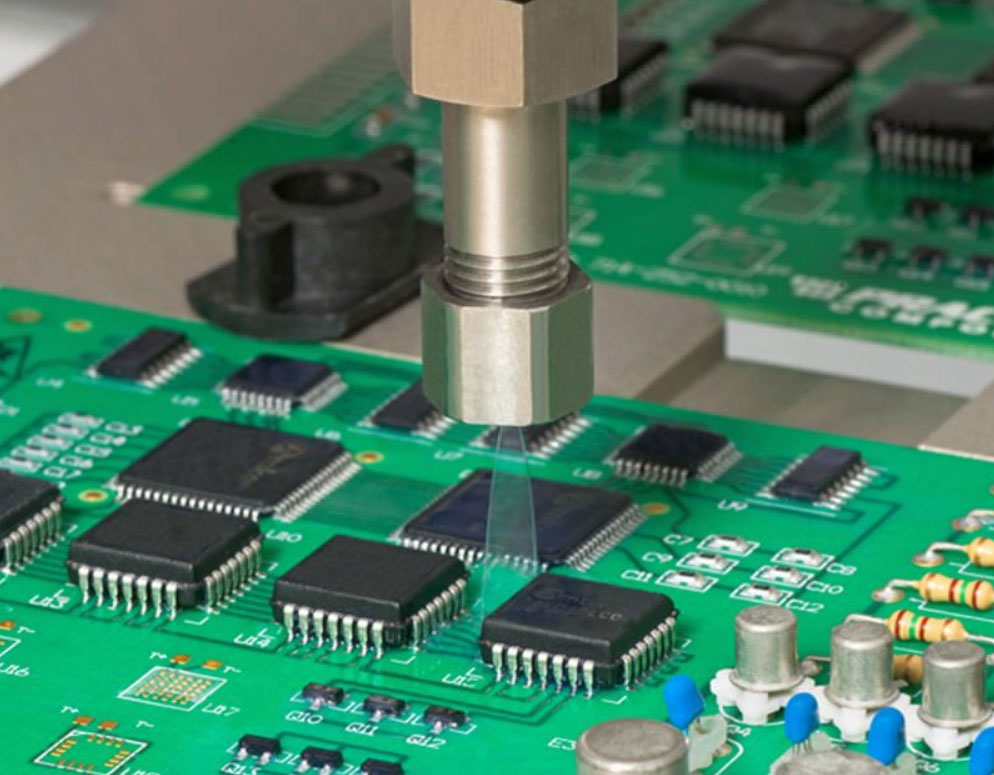

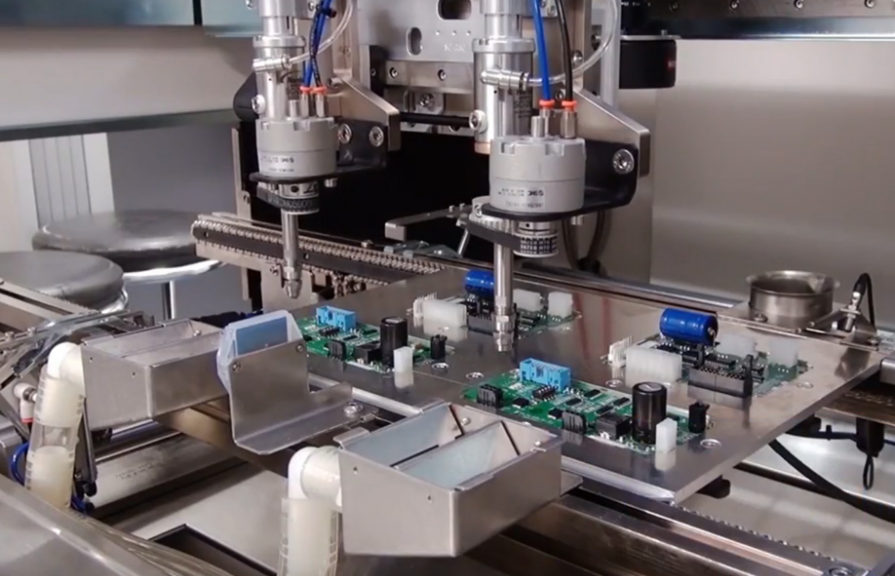

As the name suggests, it is an automated spraying process where the program sprays the system to move the PCBs on a conveyer that uses the reciprocating spray head.

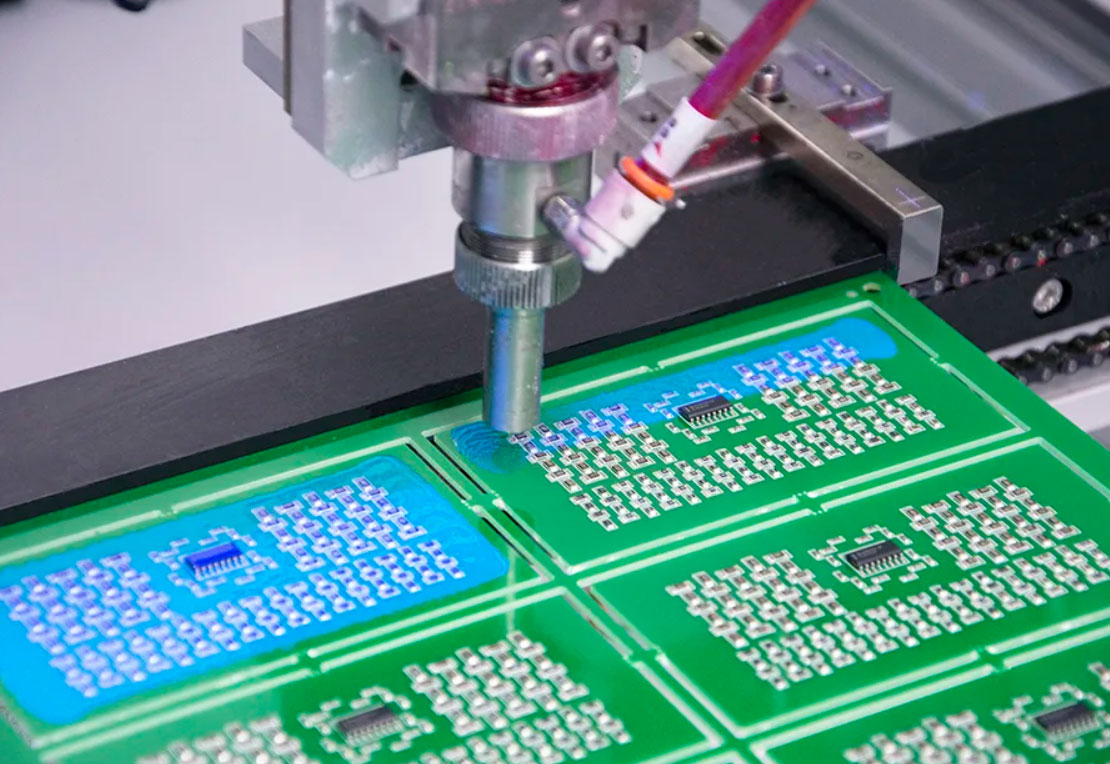

With a programmable spray system, a robotic spray nozzle can automatically spray conformal coating areas on the PCB. This technique eliminates the laborious masking process, which is popular with high-volume assembly operations.

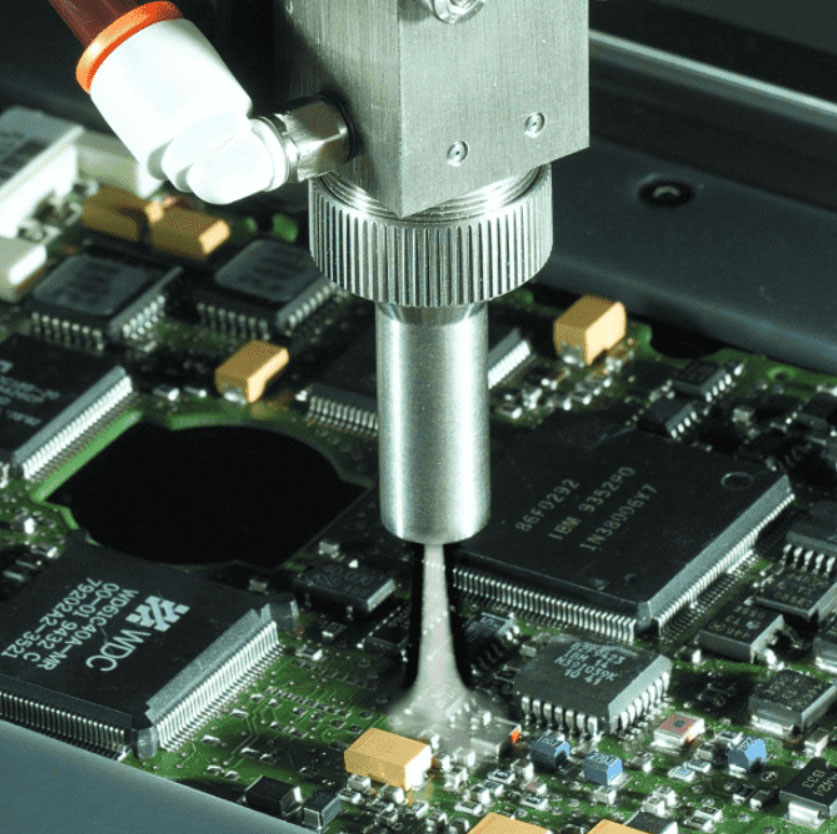

It is one of the popular conformal coatings used for high-volume assembly. Before coating the PCBs, it requires masking. It is usually handy when the board requires a coating on both sides. Besides, the immersion time, immersion speed, withdrawal speed, and viscosity determine the resulting formation of the film.

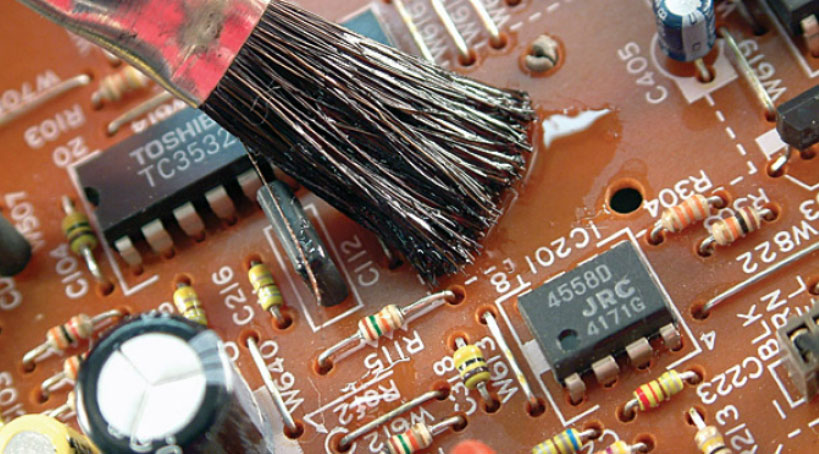

It is applied for reworking and repairing. Conformal coating is applied only to the specific area of the board. However, brushing is increasingly popular with small producers since it is both low-cost and labor-intensive.

Usually, the thin conformal coating provides the best protection minimizing excess weight loss and heat entrapment. The typical thickness of the conformal coating is 1-5 mils. There are three ways to measure the thickness of conformal coating:

You can measure the film thickness using a gauge with teeth and notches. Each of these teeth has a calibrated length. Placing the gauge into a wet film measures the thickness of the conformal coating. This would multiply the measurement by the percent solids of the coating, approximately the dry coating thickness.

By generating an oscillating electromagnetic field, a test probe measures the thickness of a coating directly. The thickness measurements are non-destructive and extremely accurate. Still, the availability of a metal backplane or metal under the layer limits them and the open contact area on the test sample. No measurements will be taken if there is no metal beneath the test area. Readings will be inaccurate if the probe is not flat on the test area (for example, a densely populated PCB).

In this process, ultrasonic wave measures the coating thickness, so there is no need for backplane-like eddy current probes. The sound wave traveling from the transducer on the board's surface measures the thickness of the board and it returns back to the coating of the transducer. A conductive medium like propylene glycol or water creates good contact.

The major thing about conformal coating and encapsulation is that both provide chemical, moisture, thermal resistance, and electrical insulation. The difference is in the level of protection that they provide. The conformal coating is a thin covering layer in the circuit board, while an encapsulation surrounds and tightly seals the PCB instead of coating them. A casing is built for encapsulating the circuit board, and thus, the encapsulating fluid is poured into it. This covers the printed circuit board with a thick protective layer.

Some of the common difference between conformal coating and encapsulation as follows:

| Conformal Coating | Encapsulation |

|---|---|

| The thinner coating increases flexibility | Thicker material is better for achieving protection |

| It is usually transparent in nature | It is darker in nature |

| Small increase in PCB weight | PCB weight increases significantly |

| Cost-effective | Expensive |

| Easy to use | Requires additional steps |

Curing for conformal coating can take from seconds to days. This depends on various curing methods, resin, coating thickness, etc. Apart from this, there are different curing mechanisms depending on the resin types:

The coating resin is left when the liquid carrier evaporates. With this principle evaporation cure, mechanisms are applied. This evaporation curing mechanism cures the PCB within an hour or can take days too.

Heat cure mechanism is applicable for the single or multicomponent system, including moisture cure, UV cure, evaporation cure, etc. Thus, heat cure works as a secondary curing mechanism as adding heat combines or accelerates the system's curing process. This kind of heat-curing mechanism is applied when one curing mechanism is insufficient.

It is mainly applied to silicone and some urethane systems. The polymer coating forms after reacting coating resin with ambient moisture. It is common practice to combine the moisture-curing process with the evaporation process. The final curing proceeds as carrier solvents evaporate. Thus, the moisture reacts with the resin. Finally, the product can be cured within an hour but can go up to a few days to cure fully.

The removable conformal coating is necessary to replace damaged components or other types of rework. Some of the methods cited by IPC are as follows:

Solvent Removal: Conformal coating dissolves in solvents, but while removing this coating, you must ensure that the solvent doesn't affect any components or the parts. Acrylic is considered one of the easiest and fastest coatings for removing with the solvent. Coating coatings like urethane and silicone can take more soak time and thus require more brushing for complete Coating removal. NextPCB offers the electro-wash two-step, which can remove the acrylic silicone and urethane coatings when heated.

Peeling: The best part of some conformal coating is; you can easily peel it from the board. This usually takes place in some flexible, conformal coatings and some silicone conformal coatings.

Microblasting: It is the process of removing the conformal coating with a concentrated mix of compressed and soft abrasive air. This process removes the coating of small areas and is common while removing epoxy and parylene coatings.

Thermal/Burn Through: It is considered one of the common methods of removing conformal coating with the help of soldering iron. This method usually works for most conformal coatings.

Grinding or Scraping: This is the conformal coating removal process with harder conformal coatings like epoxy, parylene, and polyurethane. This method is more challenging as it can result in serious damage.

It requires several specifications and tests to meet conformal coating standards for automation or military applications.

There are two closely related specifications for conformal coatings: MIL-I-46058C and IPC-CC-830B. Underwriter's Laboratories may also recognize them if they meet certain criteria, such as UL94V0 for permanent coatings or UL746E for conformal coatings.

It uses various temperature and humidity conditions to assess the material's properties in these tests, which require flat coupons coated with the conformal coating. Although assessing the potential performance of a material is perfectly acceptable, customers are more concerned with the coating's ability to protect their end-use environment.

For conformal coating materials, this is the industry standard. It is still a requirement for military contractors even though it has not been active for new designs since 1998. In addition to requiring independent testing by MIL-approved laboratories, MIL-I-46058C also maintains a Qualified Product List (QPL) based on independent test reports that were successful.

However, this standard requires suppliers to self-certify rather than MIL-I-46058C. The IEC does not maintain a QPL but utilizes independent testing labs.

IPC introduces it in place of MIL-I-46058C when the MIL spec declared it inactive as an alternative. In addition to being an active specification, CC-830 is constantly being updated. MIL-I-46058C-qualified materials are automatically assumed to meet the requirements of IPC-CC-830B.

UL94 refers to the conformal coating's flammability or self-extinguishing nature on an FR4 substrate. V-0 is the highest classification possible, with V-1 and V-2 indicating materials that burn for longer periods.

UL746E tests for both the explosive and electrical safety of the coated electronics. For electrical safety, a battery of tests related to IPC-CC-830B is available, but with current cycling, load to continuously measure the failure of the coating's isolative properties. The flammability test follows the UL94 standard, similar to IPC-CC-830B, and involves attempting to light the cured coating with an open flame and then observing the flame's sustainability.

Some of the common defects in conformal coating include:

Manufacturers test the coating under appropriate conditions to determine their performance range and limitation to ensure they meet desired characteristics. Some of these tests include:

Basic Test: The basic test includes accelerated humidity and electrical performance testing.

Advanced Testing: It includes severe conditions like temperature extremes, salt mist, and rapid environmental changes.

Humidity Testing: Moisture in the atmosphere can react with metal components and connections on the board, making humidity one of PCBs' most obvious causes of corrosion. Humidity testing maintains its resistance to humidity.

Corrosive Gas Testing: Corrosive gas testing entails exposing PCBs to a mixed gas environment composed of hydrogen sulfide and sulfur dioxide according to BS EN 60068-2-60, method 1.

The use of surface insulation resistance evaluates each coating's performance in this condition or environment.

Electrical Testing: The evaluation and identification of electrical properties are important for almost all conformal coating. Some of the electrical tests include:

The use of conformal coating can protect your PCB. Thus, it would help if you made some considerations before selecting the right conformal coatings. It would help if you considered the following factors for choosing the right PCB coating:

Before selecting the right coating for your PCB, ensure to select the correct operating conditions, including humidity, temperature range, salt presence, UV level, etc.

The conformal coating forms an insulating layer. Surface Insulating Resistance (SIR) is the most common electrical parameter. It takes the measurements before and after placing the board in harsh conditions. The measurement is recorded and ensures that the coating provides the insulation level as required. For considering the right conformal coating, ensure that the coating exhibits high dielectric strength. The potential difference between the adjacent tracks and intertrack separation determines the minimum requirements.

Thus, choosing the best conformal coating involves understanding the board's requirements and deciding which coating would provide you the protection for your PCB. The conformal coating type will depend on the operating temperature of the board. Silicon is suggested to use in temperatures greater than 160℃. Besides, the next crucial consideration is the rework, repair, and upgrades. Although the coating is the best option to protect your PCB, the factors like time-consuming and costlier repairs can make it challenging. On the other hand, if you require a constantly changing board, choose the coating that suits your changing requirements.

Thus, conformal coating is one of the most crucial steps in the PCB assembly process. We hope this article solves more unanswered questions regarding conformal coating. NextPCB provides you with the necessary PCB-related services, including all types of conformal coating. Feel free to contact us for all your PCB-related services.

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now

|

Dimensions: (mm) |

|

|

Quantity: (pcs) |

|

|

Layers: 2 |

Thickness: 1.6 mm |

|

|

|