Support Team

Feedback:

support@nextpcb.com94V-0 is a printed circuit board that meets the highest flammability standards and can withstand harsh environmental conditions. Mainly the 94V-0 focuses on the flammability of the circuit in the worst situations.

The UL 94V-0 is a testing method to check the printed circuit boards against their flammability and fire-extinguishing properties. Hence, a UL 94V-0 printed circuit board indicates a circuit board designed and manufactured considering the flammability standards to meet the highest quality and reliability.

In the most simplified terms, the UL 94V-0 test checks the plastic's capability to extinguish the fire in the least possible time. Designing and manufacturing a UL 94V-0 printed circuit board means developing a PCB that can not burn for more than 10 seconds.

The UL 94V-0 meets the standards of the International Organization for Standardization (ISO). It also shows the compatibility with the International Electrotechnical Commission (IEC) 60695-11-10:2013 and 60695-11-20, also with ISO 9772:2012 and 9772:2012 and 9773:1998.

Speaking further about the UL 94V-0 PCBs, it is merely a circuit board designed to fulfill the specifications of a test destined to measure the integrity of the board's plastic material against fire. It is crucial to test the flammability of the material used in the printed circuit board. Because PCBs go through extreme heat throughout their lives. Hence, they are likely to ignite the fire. Different PCB substrates have diverse levels of flammability. The NextPCB states the flammability level of some materials. So that when next time you see a PCB's label, you already know what it means.

V-0: This test is taken on a verticle scale, and the burning should be no more than 10 seconds. Concerning its parameters, it is the most strict test on PCBs against their flammability check. Hence, it does not allow any flamming drips.

V-1: To pass the V-1 test, the specimen's burning should cease in about 30 seconds. It is also a vertical scale test and does not allow any drips out of the sample.

V-2: This is also a vertical flame test. It has a burning session of about 60 seconds and allows some flame drips.

5VA: 5VA is another verticle test on a specimen. The surface burning in this scenario stops within 60 seconds. The test sample should not ignite for more than 60 seconds under flame after the fifth application of the test flame. Neither the specimen should witness a burn-through hole on the surface. The ideal specimen thickness of the 5VA material is 2.5m.

5VB: This rating indicates that the surface burning should cease in about 60 seconds. The parameters of this test do not allow any flame drips. However, the specimen may experience burn-through, or holes may appear on the sample's surface.

HB: Horizontal Burn (HB) is the lowest fire rating in the UL 94 flammability standards. This test requires that a specimen of thickness between 3 to 13 mm should have a burn rate lower than 40mm per minute, and the fire should extinguish before it reaches 100 mm of the length of the test sample.

Till now, you have understood the different test ratings of the UL 94 classification. Now, to understand the UL 94V-0 more understandably, let's have a look at this chart.

| Test Criteria | V-0 | V-1 | V-2 |

|---|---|---|---|

| After Flame Time 1 | < 10 seconds | < 30 seconds | < 30 seconds |

| After Flame Time 1 | < 10 seconds | < 30 seconds | < 30 seconds |

| Did flame reach the top of the specimen? | No | No | No |

| Cotton Indicator Ignited? | No | No | Yes |

From the chart, it's obvious that the UL 94V-0-rated printed circuit boards provide the highest performance and protection against fire.

The UL 94V-0 printed circuit boards not only act robust against fire. But they can perform well against harsh environmental conditions. Usually, the UL 94V-0 devices are durable and last longer than the other circuit boards. These features and qualities of the 94V-0-rated circuit board extend the overall life of its parent device and guarantee its performance till its very end.

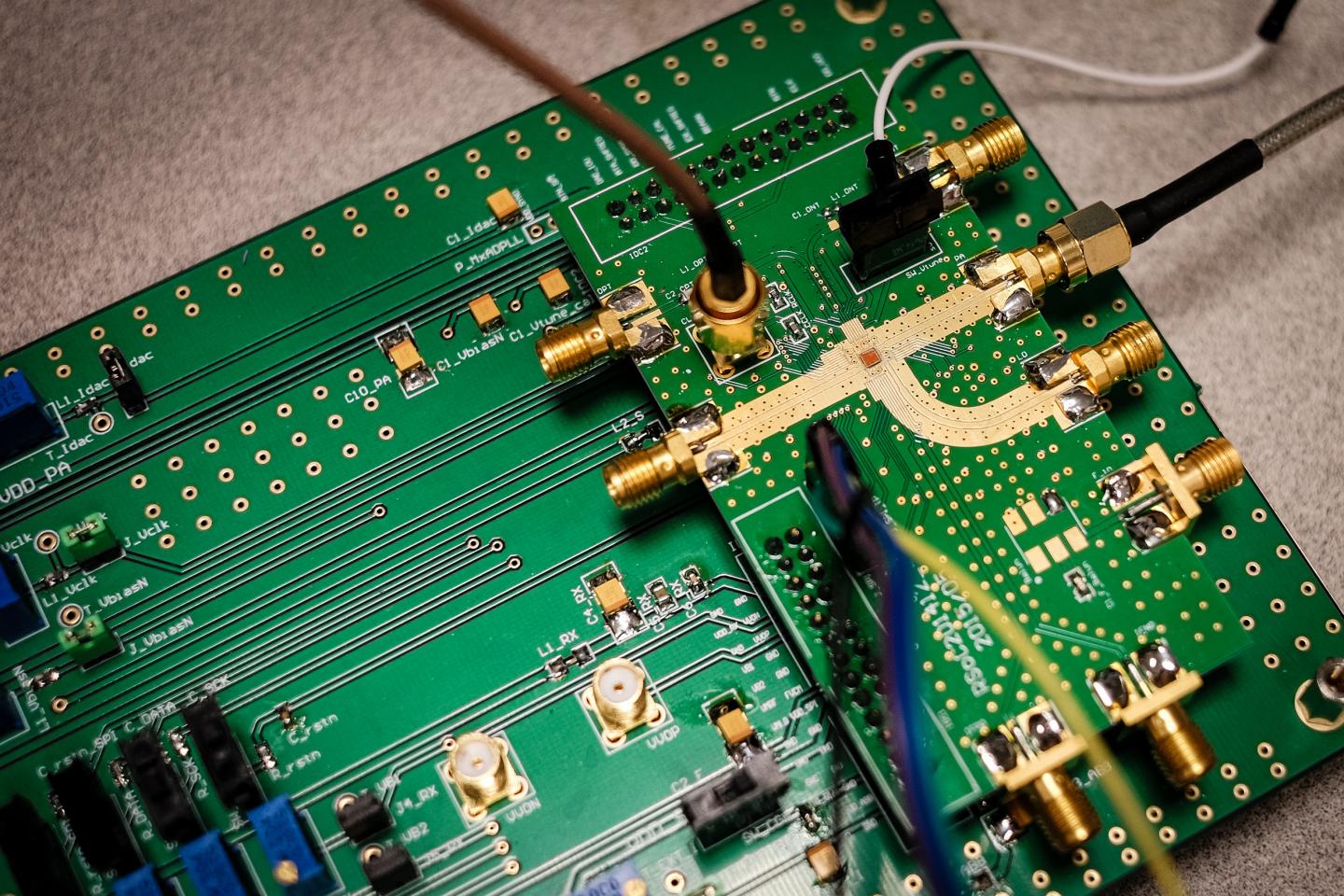

Another overwhelming feature and a big cause of using V-0-rated PCBs in military-grade, aerospace, and other heavy-duty devices are that UL 94V-0 PCBs come with the highly desirable feature of temperature control or modulation panels. This feature helps control the temperature of the device by regulating it and preventing issues due to overheating.

The thickness of a printed circuit board is of great importance because it influences the PCB's features and has a direct relationship with the heat and flame-dissipating properties of the circuit board. Hence, a flammability test should always perform on the circuit board with individual thicknesses before using it.

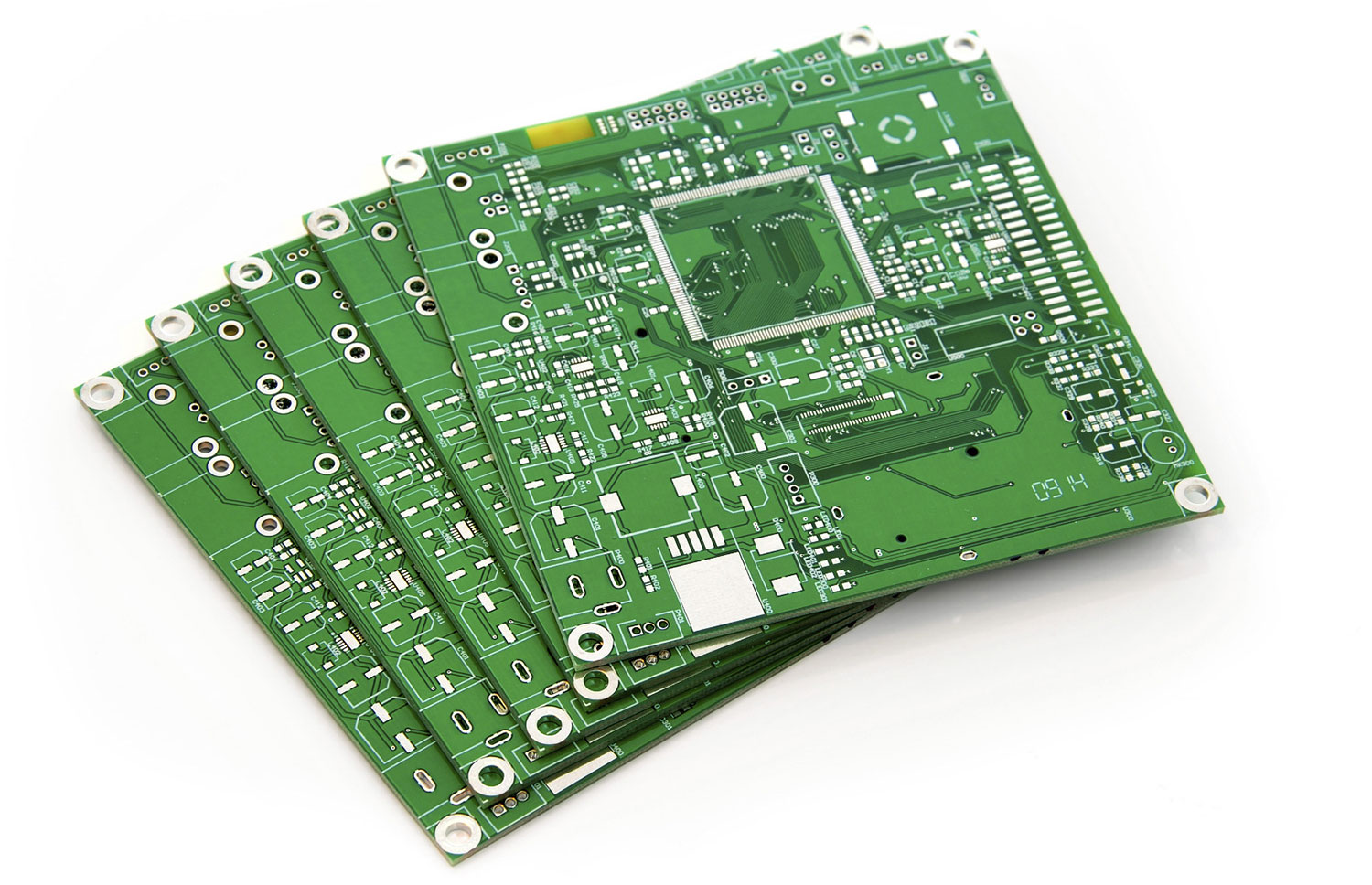

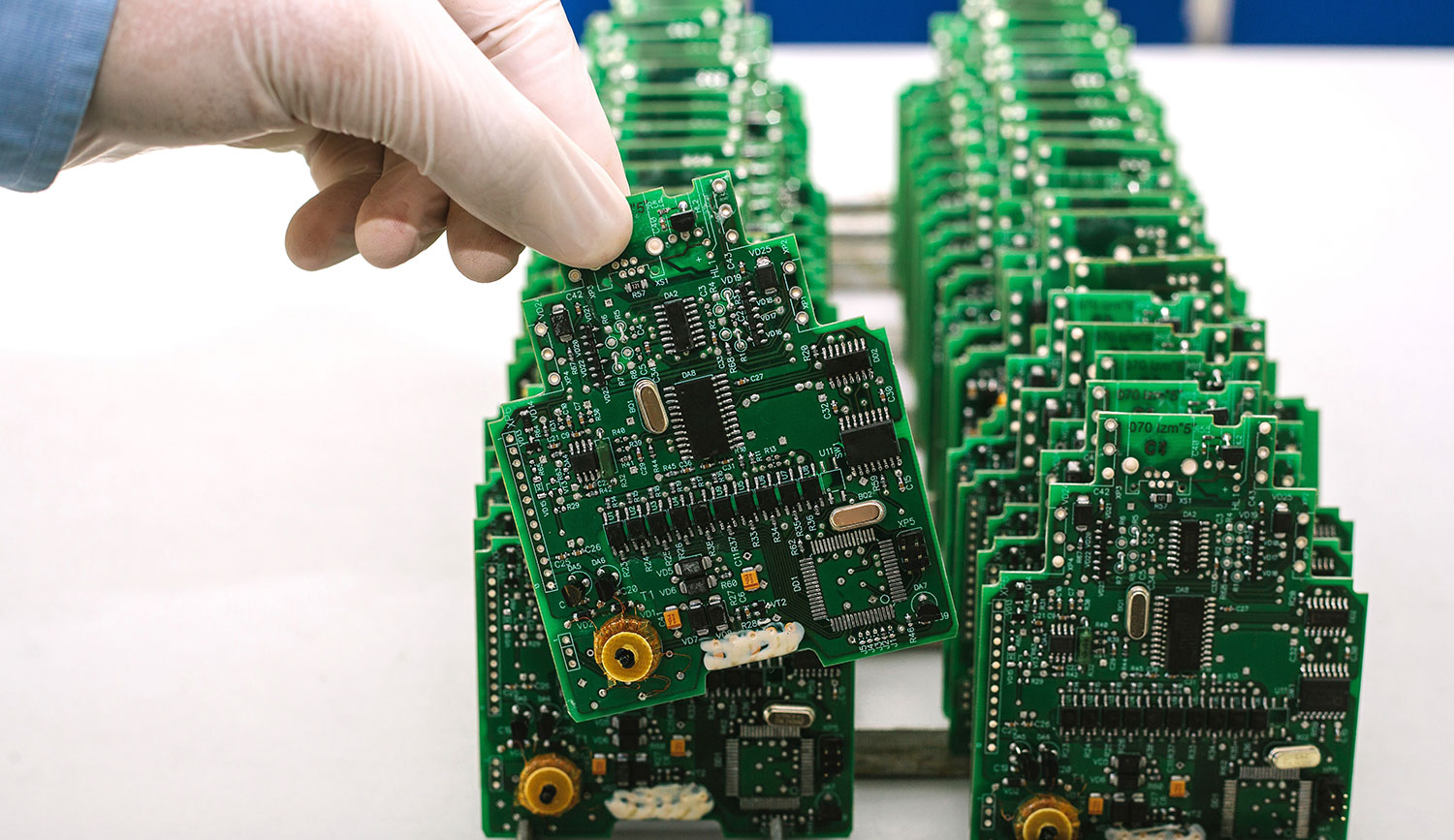

To produce the finest quality printed circuit boards, the manufacturers pass the specimen of each circuit board through different PCB tests, including thermal and power shock tests, flying probe tests, automatic optical inspection, in-circuit testing, and functional testing. These tests help determine how the final circuit board will behave under harsh environmental conditions. Further, these tests with the UL 94V-0 flammability test are a must to ensure the safety of the user and the product.

The UL 94V-0-rated printed circuit boards have a wide application in military-grade, aerospace, automation, and other sensitive industries, but do we need them in consumer electronics? OR should we use UL94-0-rated circuit boards in consumer electronics? The simple and stable answer is YES. We should use them in consumer electronics. Because the V-0 boards are not only robust against fire but also provide exceptional performance in all other aspects. Incorporating these circuit boards into your devices will bring a new level of consumer experience to your customers, which they will like.

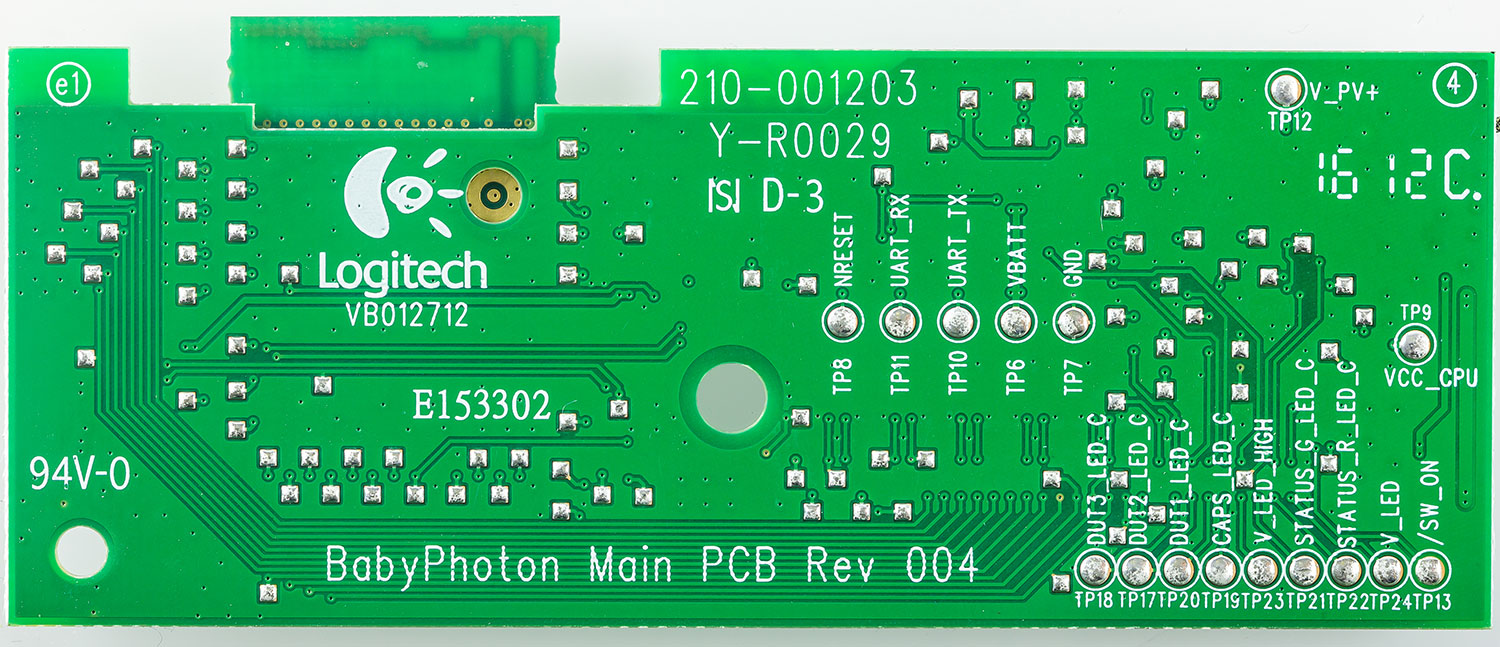

The first and most important thing to note is that any printed circuit board with a 94V-0 rating will have a 94V-0 mark located in the bottom left corner of the board. This rating is based on the UL 94 flammability test classification, which is regulated by the International Electrotechnical Commission (IEC). Specifically, for a 94V-0 rating, a vertical specimen must stop burning within 10 seconds and any dripping particles must not be inflamed.

The UL 94V-0 circuit boards are high in cost. Hence, you are not likely to see them in consumer electronics. However, they have a wide application in the more sensitive industries where a minor error could lead to a big mess. Despite their high-cost still, some producers use V-0-rated printed circuit boards in consumer electronics to produce prime-quality devices. The applications of these circuit boards are in the following fields and industries.

A PCB substrate is the base material used to separate the two copper layers from each other. From a bare PCB point of view, the substrate holds the most weightage in a PCB. It could be a single material like ceramic or a composite material that combines two or more materials to form a single high-quality material with excellent chemical, physical, mechanical, and environmental properties. The two materials or PCB substrates that best match the parameters required to pass the UL 94V-0 test are FR-4 and Ceramic, etc.

FR-4 is a composite material made of woven or non-woven fiber-glass impregnated with epoxy resin. The FR-4 is the most widely used PCB substrate. It is a fire-extinguishable material, which means it has the property to extinguish fire itself.

To read about FR-4 PCB substrate in detail, please follow NextPCB's Guide to FR-4 Printed Circuit Board (PCB) Material.

Ceramics is another fire-resistant material that can not ignite a fire. It also provides other exceptional properties. For instance, it offers excellent mechanical strength, lower loss tangent, and a stable dielectric constant higher. However, ceramic is likely to crack if imposed under extreme heat.

Related: Ceramic PCB: Its Materials, Types, Benefits and Drawbacks

The cost of a UL 94V-0 printed circuit board varies from manufacturer to manufacturer. However, other fixed parameters may include layer count, size, and thickness of the circuit board.

But on a rough note, a UL 94V-0-rated FR-4 PCB may cost somewhere between $ 0.01 and 85.

But it is possible to save PCB costs; by sharply routing the signal tracks and reducing its surface area. Further, selecting a local manufacturer who provides the best quality at the most reasonable prices can also reduce the cost of UL 94V-0-rated printed circuit boards.

NextPCB has been providing PCB manufacturing, assembling, and testing services for more than 15 years. If you are seeking a manufacturer for your UL 94V-0-rated or any other sort of PCB, the NextPCB could be the best option for you. Since we believe in providing the highest-quality, fastest delivery and excellent customer support before and even after the project delivery. NextPCB also provides component sourcing through HQonline with proper testing to ensure the delivery of an error-free PCB. To get an instant quote on your UL 94V-0-rated printed circuit board. Please get an instant PCB quote now.

The UL 94V-0 circuit boards are the special PCBs that meet the parameters of the International Electrotechnical Commission IEC's flammability rating of the category V-0 under the classification of UL94. These circuit boards are usually robust against thermal stress, and if somehow a fire ignites, they perform excellently without causing considerable harm to the environment. The UL 94V-0 circuit boards are considered a must for military-grade, aerospace, and intense heat-generating consumer appliances to ensure the device's performance and safety of the consumer.

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now

|

Dimensions: (mm) |

|

|

Quantity: (pcs) |

|

|

Layers: 2 |

Thickness: 1.6 mm |

|

|

|