Support Team

Feedback:

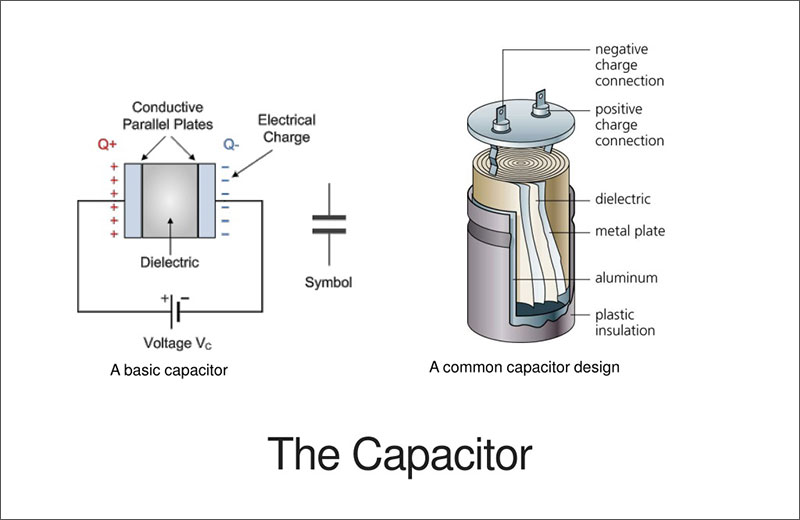

support@nextpcb.comThe energy of an electric current can be stored in a capacitor. Because of that, they serve multiple tasks in electronics, including filtering high-frequency signals, smoothing power supply voltages, and blocking DC currents, making them crucial components. Capacitors exist in a wide variety of shapes and sizes, each with its own set of characteristics that must be chosen with care depending on the intended use. A capacitor's performance and dependability are directly tied to how well it is chosen and used in an electrical circuit. Therefore in the schematic diagrams capacitor symbols play an important role.

In this article,

The capacitor symbol serves to uniformly depict capacitors in electrical schematics and circuit designs. Important information about the capacitor's kind, value, and orientation in the circuit can be gleaned from its symbol. Without having to physically inspect the component, they help engineers and technicians determine the capacitor's purpose and characteristics. Standardized capacitor symbols in circuit diagrams can assists designers and manufacturers communicate effectively and consistently.

Electronics experts and enthusiasts must understand capacitor symbols for numerous reasons. First, it helps them choose the right capacitor for a circuit based on its kind, value, and orientation. Second, it ensures the capacitor is appropriately fitted in the circuit, which is crucial for performance and dependability. Finally, capacitor symbols are needed to read circuit diagrams and construct and troubleshoot electronic circuits. Electronics professionals and enthusiasts must comprehend capacitor symbols.

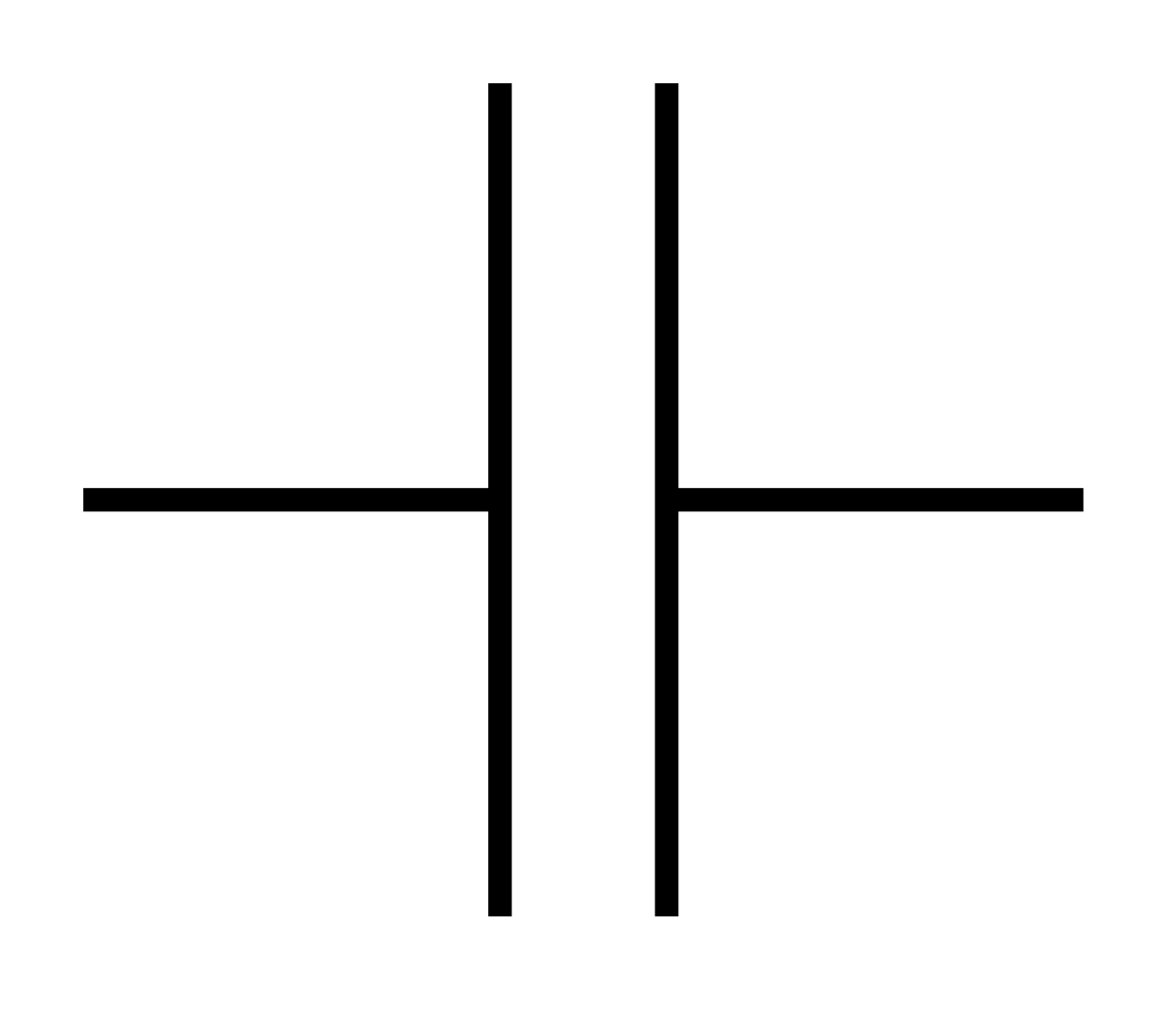

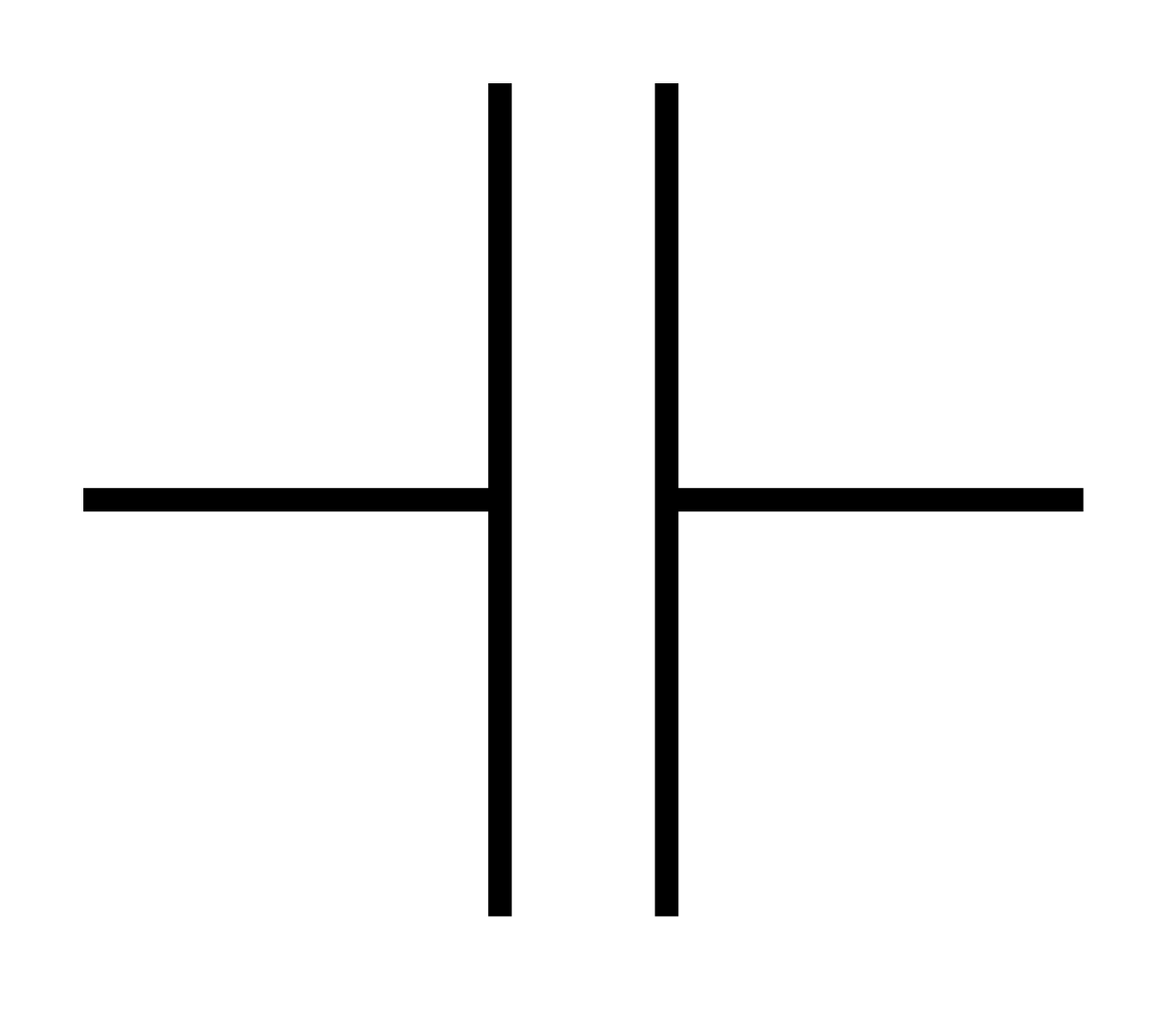

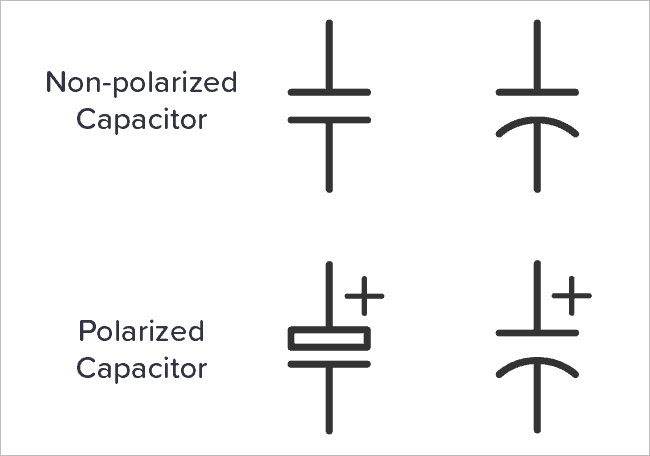

Circuit diagrams show capacitor plates as two parallel lines with a space between them. This symbol indicates a capacitor in a circuit and its approximate placement. This symbol does not indicate the capacitor type, value, or orientation.

The capacitor type, capacitance value, voltage rating, and orientation (if polarized) are needed to comprehend and use the basic capacitor symbol in circuit designs. A component specification sheet or circuit diagram symbols can provide this information. To pick and install the right capacitor in the circuit, carefully consider this information.

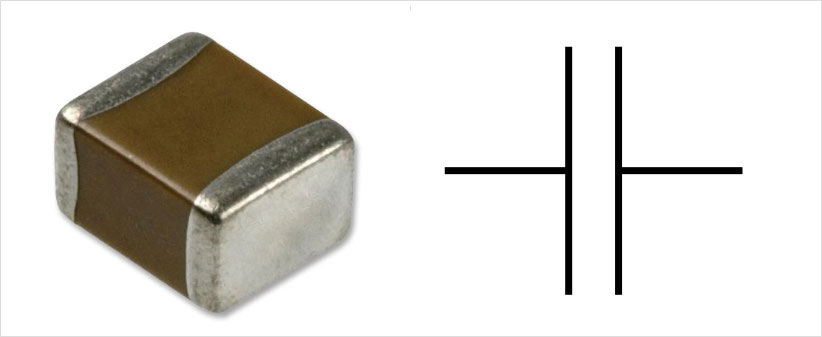

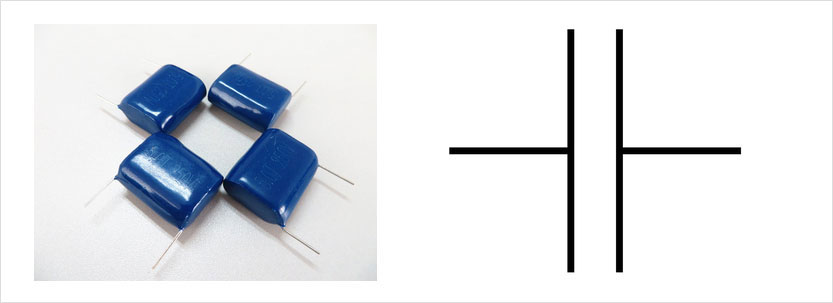

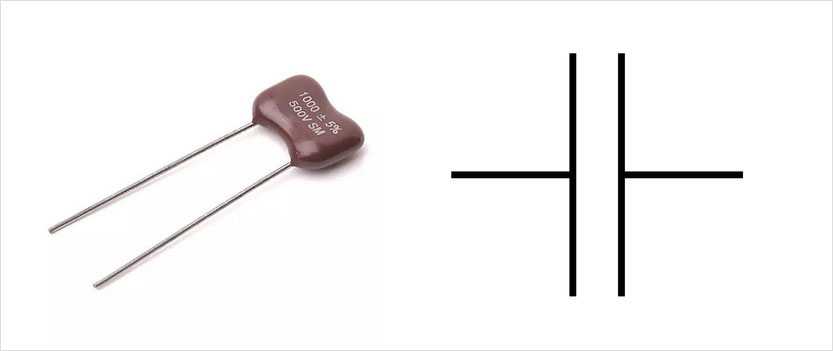

| Image | Capacitor symbol | Type |

|---|---|---|

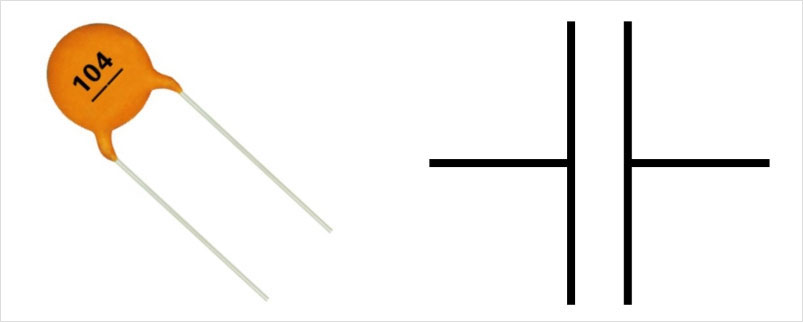

|

|

Disc ceramic Capacitor |

|

|

Multilayer Ceramic Capacitor (MLCC) |

|

|

Metalized Film Capacitor |

|

|

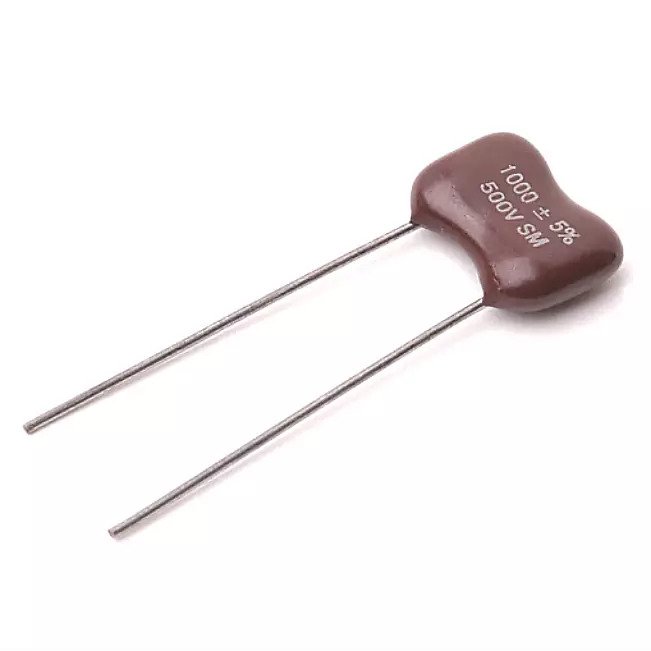

Mica Capacitor |

|

|

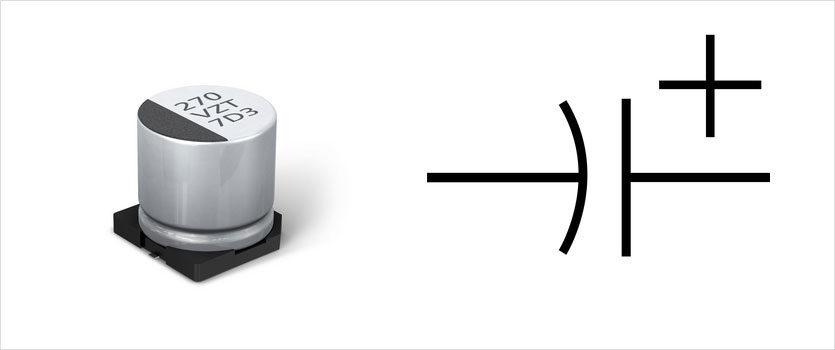

Aluminum Electrolytic Capacitor |

|

|

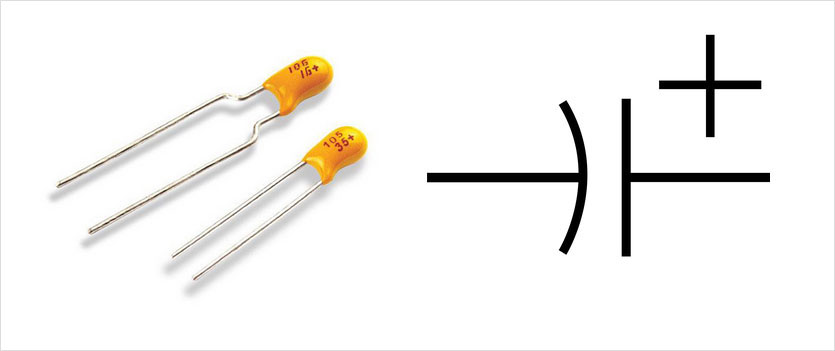

Tantalum Electrolytic capacitor |

|

|

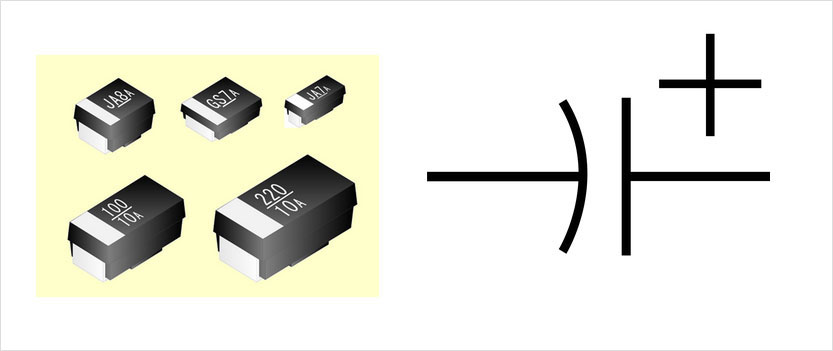

Niobium Electrolytic Capacitor |

|

|

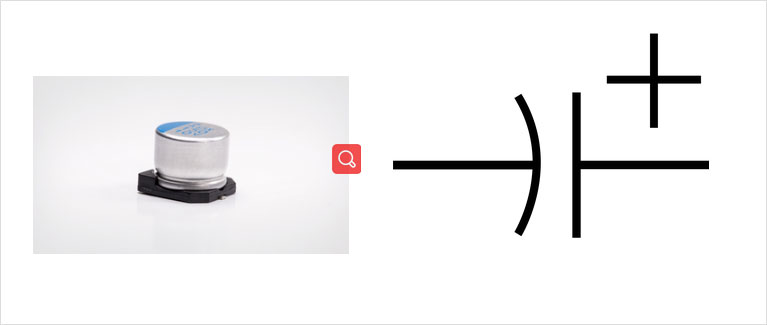

Aluminum Polymer Capacitor |

|

|

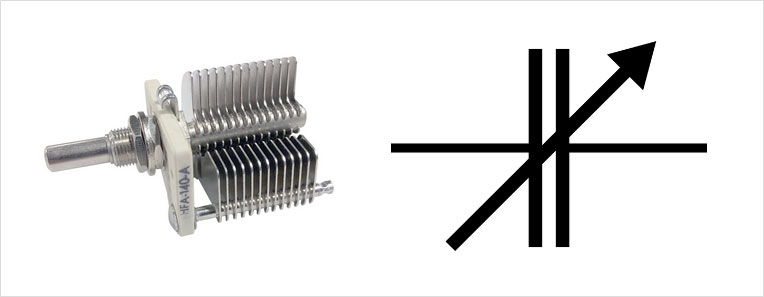

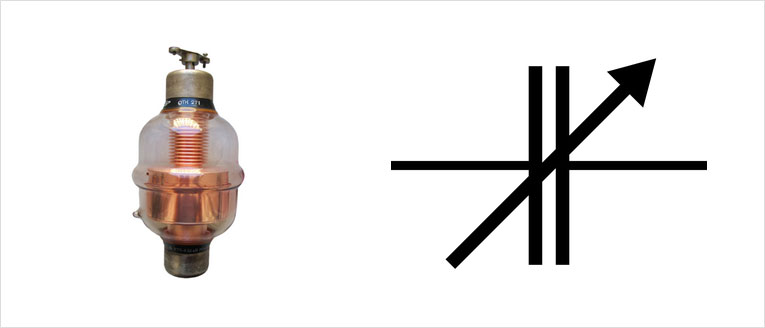

Variable Vacuum Capacitor |

|

|

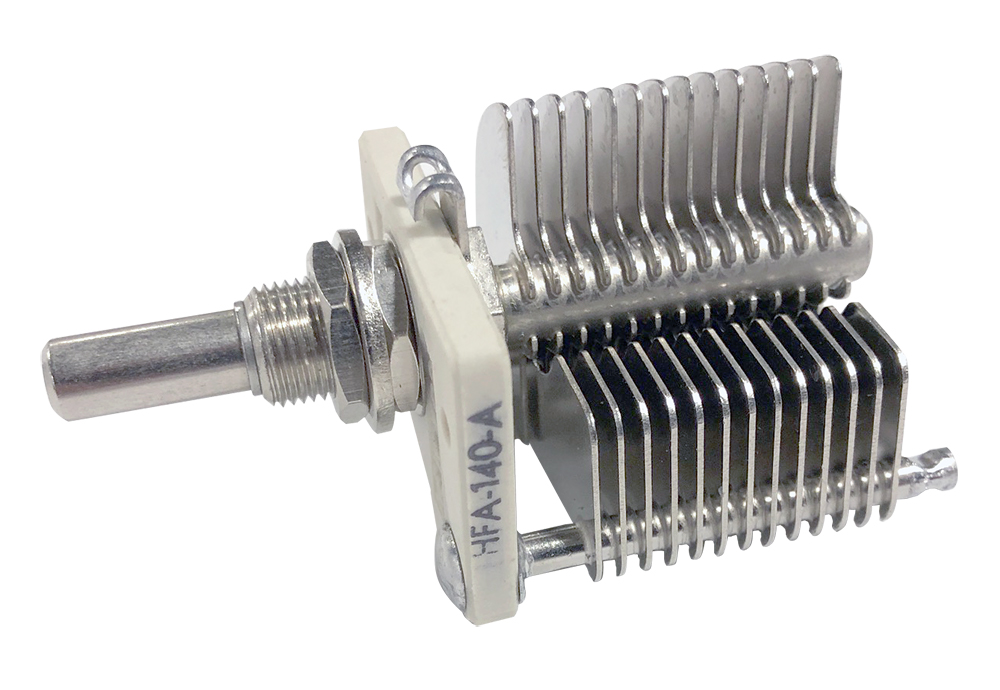

Variable Air Gap Capacitor |

|

|

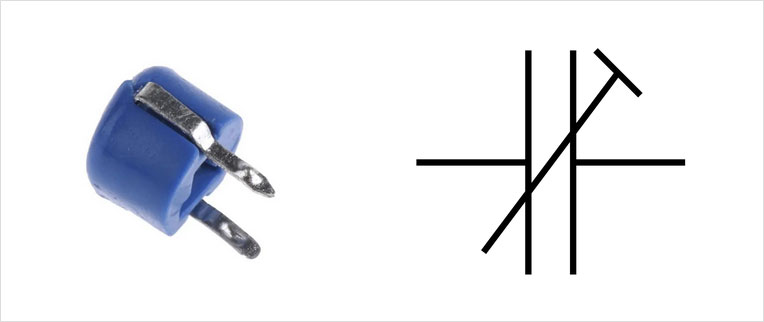

Ceramic Trimmer Capacitor |

|

|

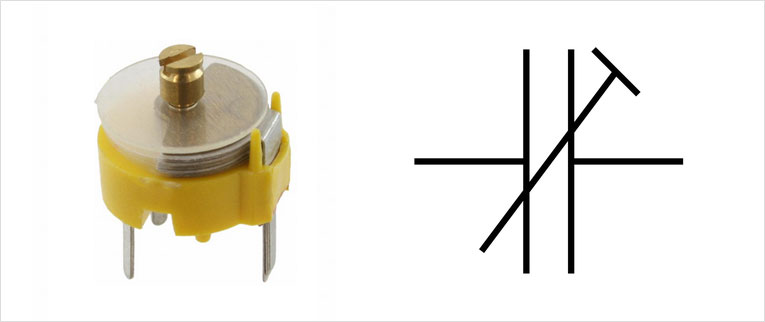

Film Trimmer Capacitor |

|

|

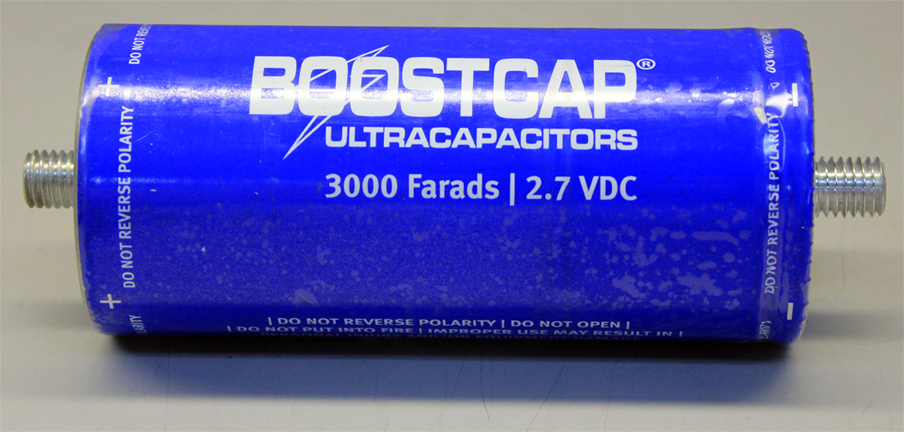

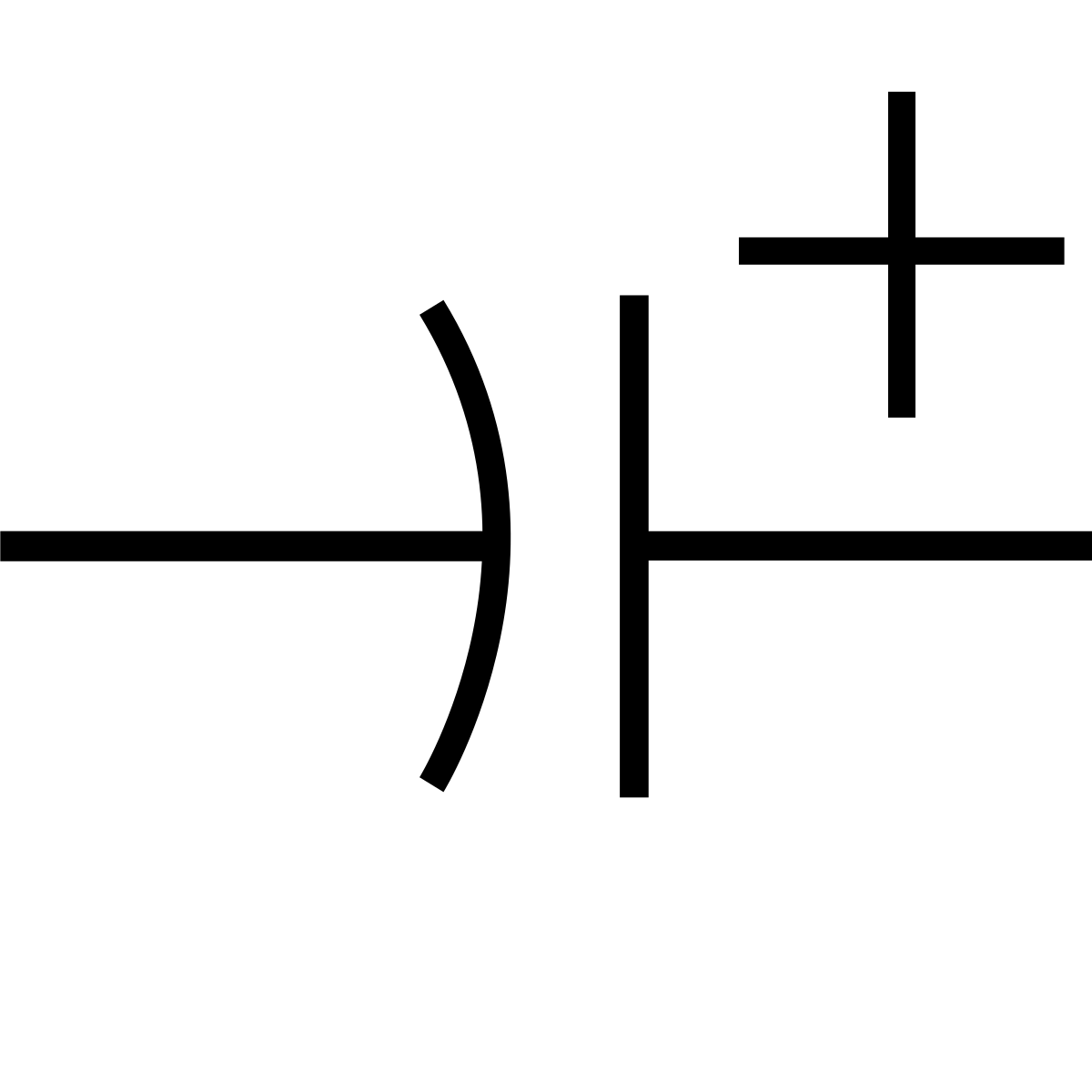

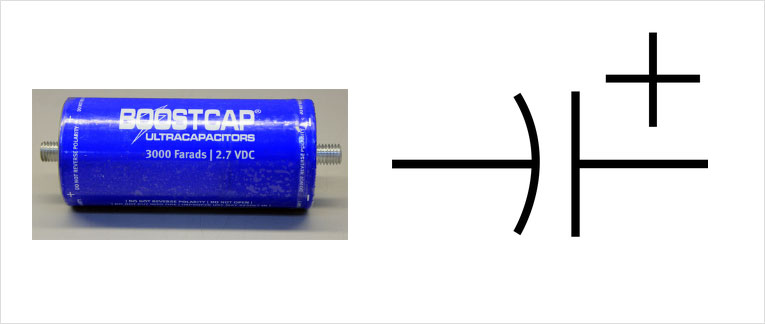

Supercapacitor |

|

|

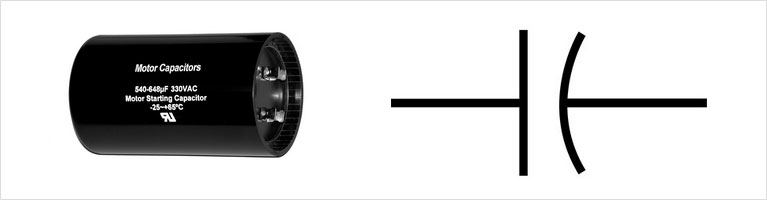

Motor Run and Start Capacitor |

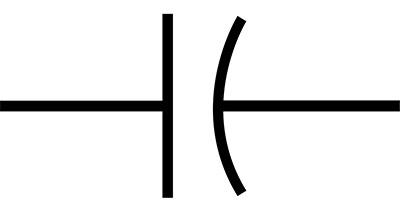

Circuit diagram symbols for fixed capacitors vary by kind. A fixed capacitor is usually represented by two parallel lines whose length represents its capacitance. Another typical capacitor sign is a rectangle with a straight line on one end, symbolizing the positive terminal. The rectangle's negative terminal is usually a curved line or no line.

The symbol for a fixed capacitor depends on the capacitor type and the circuit diagram designer or engineer's preference.

Electronic circuits frequently use disc ceramic capacitors. They are ceramic discs with metal electrodes on both sides. Disc ceramic capacitors are versatile because its dielectric is steady and trustworthy.

Disc ceramic capacitors have capacitance values from a few picofarads to a few microfarads. They can handle several hundred volts. Power supply, filters, and timing circuits use disc ceramic capacitors due to their small size, low cost, and reliability.

In circuit designs, disc ceramic capacitors are rectangular or oval with electrodes on opposing sides. The capacitance value and voltage rating will always be labeled, however the form and symbol may change based on circuit diagram norms.

Multilayer ceramic capacitors (MLCC) have ceramic layers with metal electrodes on alternate sides. In order to attain the appropriate capacitance, ceramic layers are stacked as dielectrics.

MLCCs' tiny size, high capacitance, and inexpensive cost make them popular in electronic circuits. They can handle several hundred volts and have capacitance values from a few picofarads to tens of microfarads. Power supply, decoupling circuits, timing circuits, and other electronics use MLCCs.

Film capacitors have two conducting plates separated by a thin plastic or polymer film. Their stability, low loss, and reliability make them popular in electrical circuits. Film capacitor symbols in circuit designs vary by construction and features.

Film capacitors are usually represented by a rectangle with rounded corners and a straight line on one end for the positive terminal. The rectangle's negative terminal is a curved line or no line. It resembles other fixed capacitor symbols.

Polyester, polypropylene, polystyrene, and other film capacitor use thin plastic dielectrics. Therefore their stability, low losses, and durability make them popular in electrical circuits.

Mylar capacitors are comprised of a thin polyester sheet with metal electrodes on either side, because of that they are inexpensive and utilized in audio circuits, power supplies, and general-purpose applications.

Polypropylene capacitors are thin polypropylene films with metal electrodes on either side. High-frequency applications like filters and tuning circuits benefit from their superior stability and lower losses than polyester capacitors.

Polystyrene capacitors are thin polystyrene films with metal electrodes on either side. The most stable and low-loss film capacitors are also the most expensive and rare.

Polyphenylene sulfide (PPS) and polytetrafluoroethylene (PTFE) film capacitors have great temperature stability and high-frequency properties, respectively.

Metalized film capacitors employ a thin plastic film as the dielectric and a metal coating on one or both sides as electrodes. Metalization deposits aluminum or zinc onto the plastic sheet.

Metalized film capacitors are popular in electronic circuits due to their stability, minimal losses, and reliability. They are excellent for a multitude of applications due to their capacitance, voltage, and temperature ranges.

For their stability and durability, electronic circuits use mica, glass, and other permanent capacitors. Oscillators, filters, and resonant circuits employ them for precision.

Mica capacitors are thin mica sheets with metal electrodes on either side. For high-frequency applications, they are stable and low-loss. RF, filter, and high-precision timing circuits require mica capacitors.

Glass capacitors are ceramic capacitors with metal electrodes. High capacitance applications suit them due to their high dielectric constant. Power supply decoupling circuits and other applications requiring high capacitance and stability employ glass capacitors.

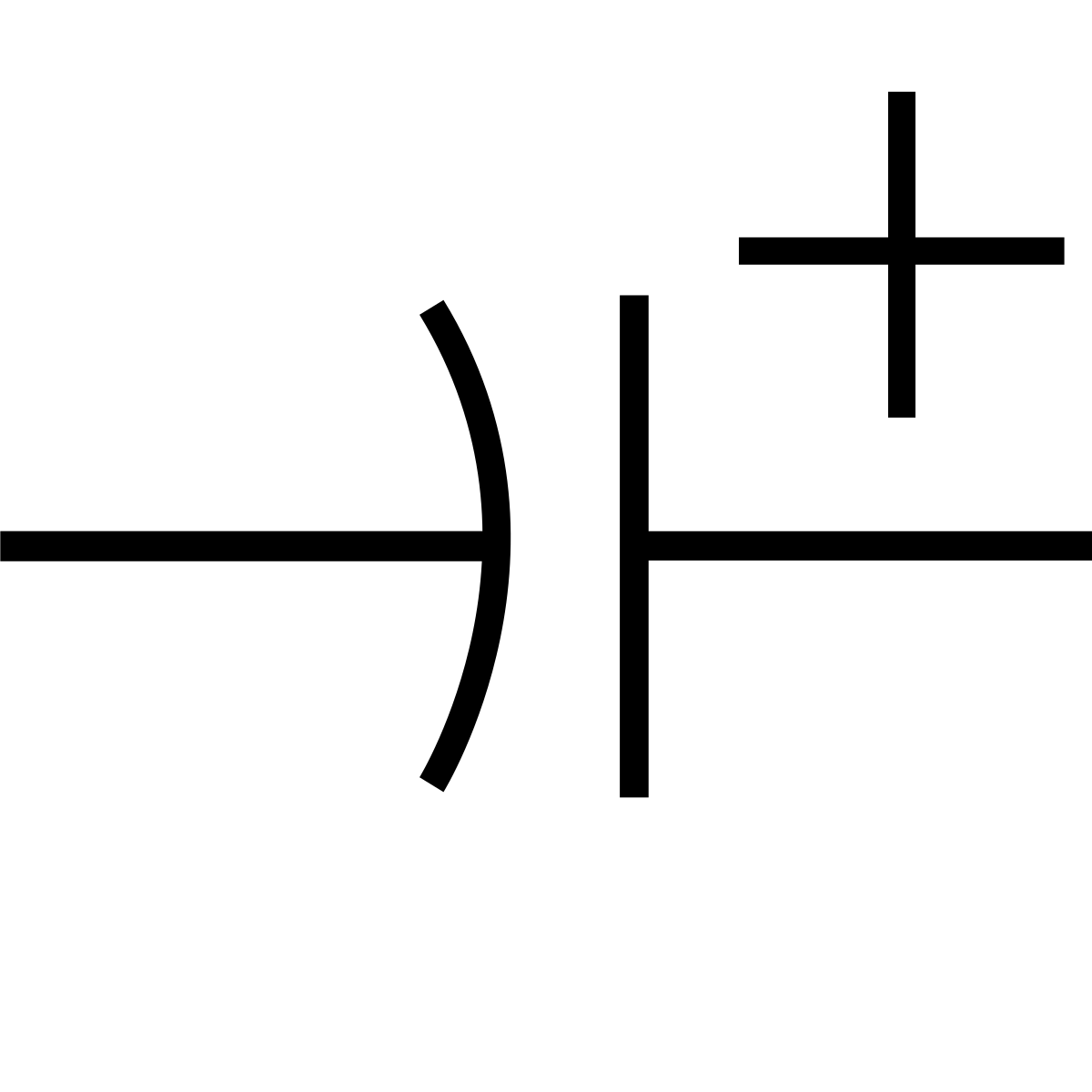

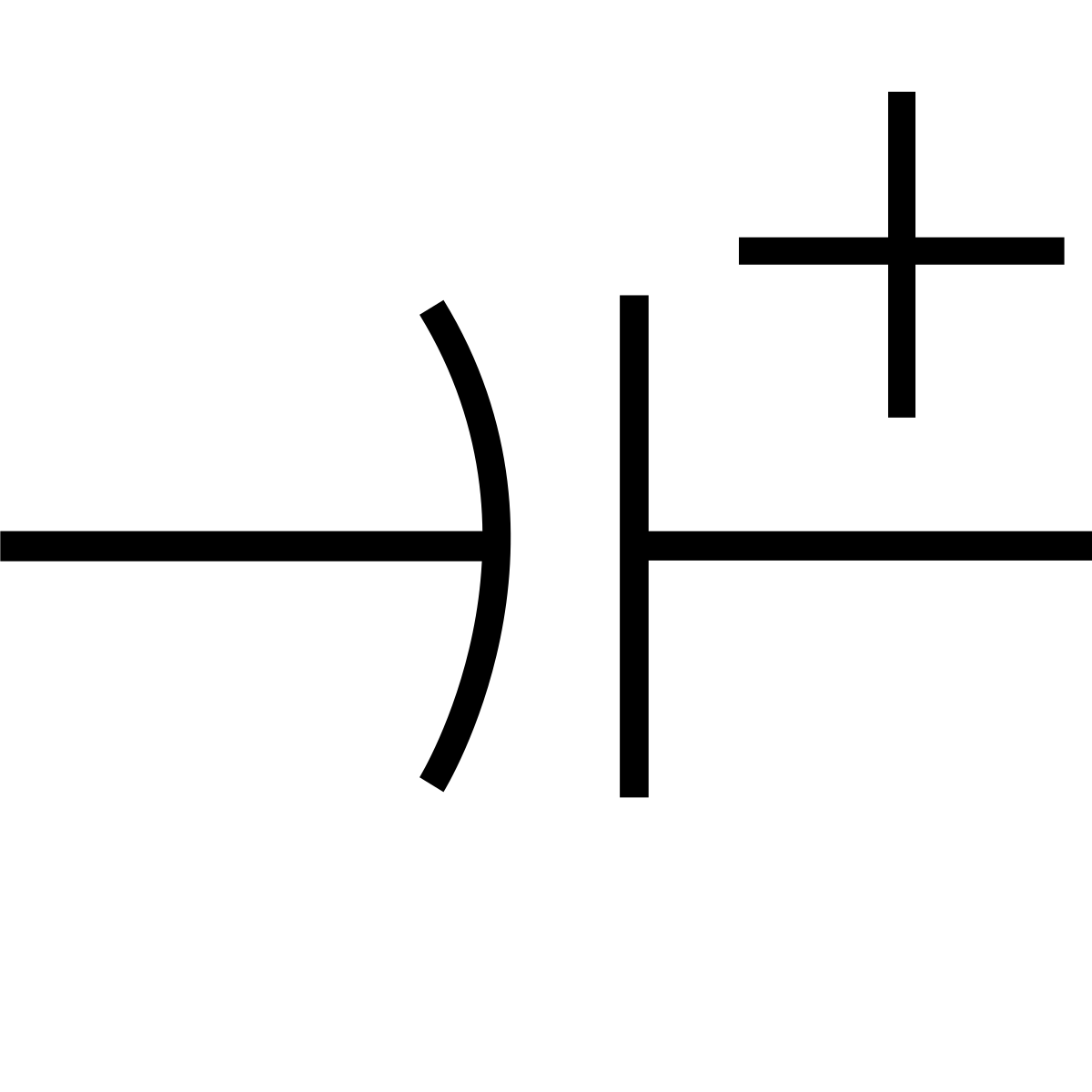

The symbol of polarized capacitors contains positive and negative leads and must be linked in the circuit correctly to work. These polarized capacitor symbols in circuit diagrams show their polarity and design.

Aluminum electrolytic capacitors employ aluminum oxide as dielectric. Their high capacitance, high voltage, and low cost make them popular in electrical circuits.

In order to function, Aluminum electrolytic capacitors have positive and negative terminals and must be connected to the circuit correctly.

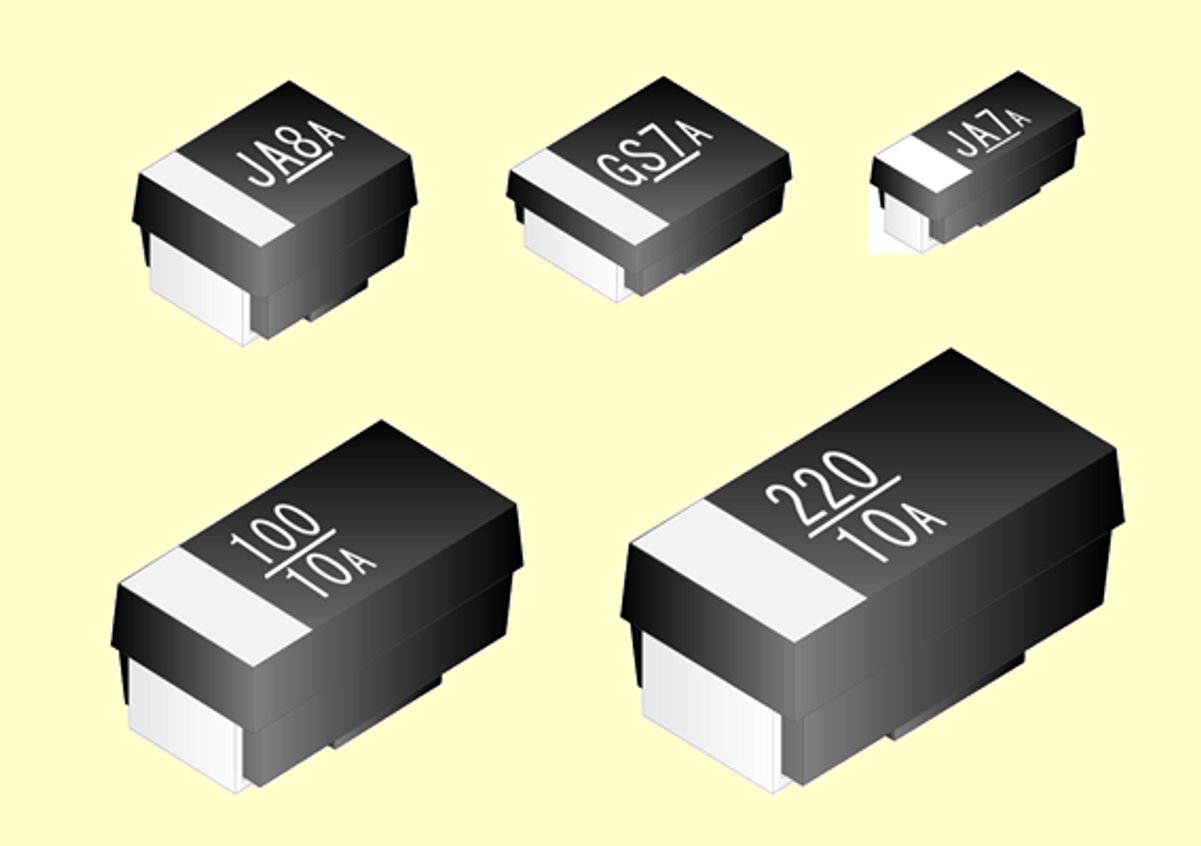

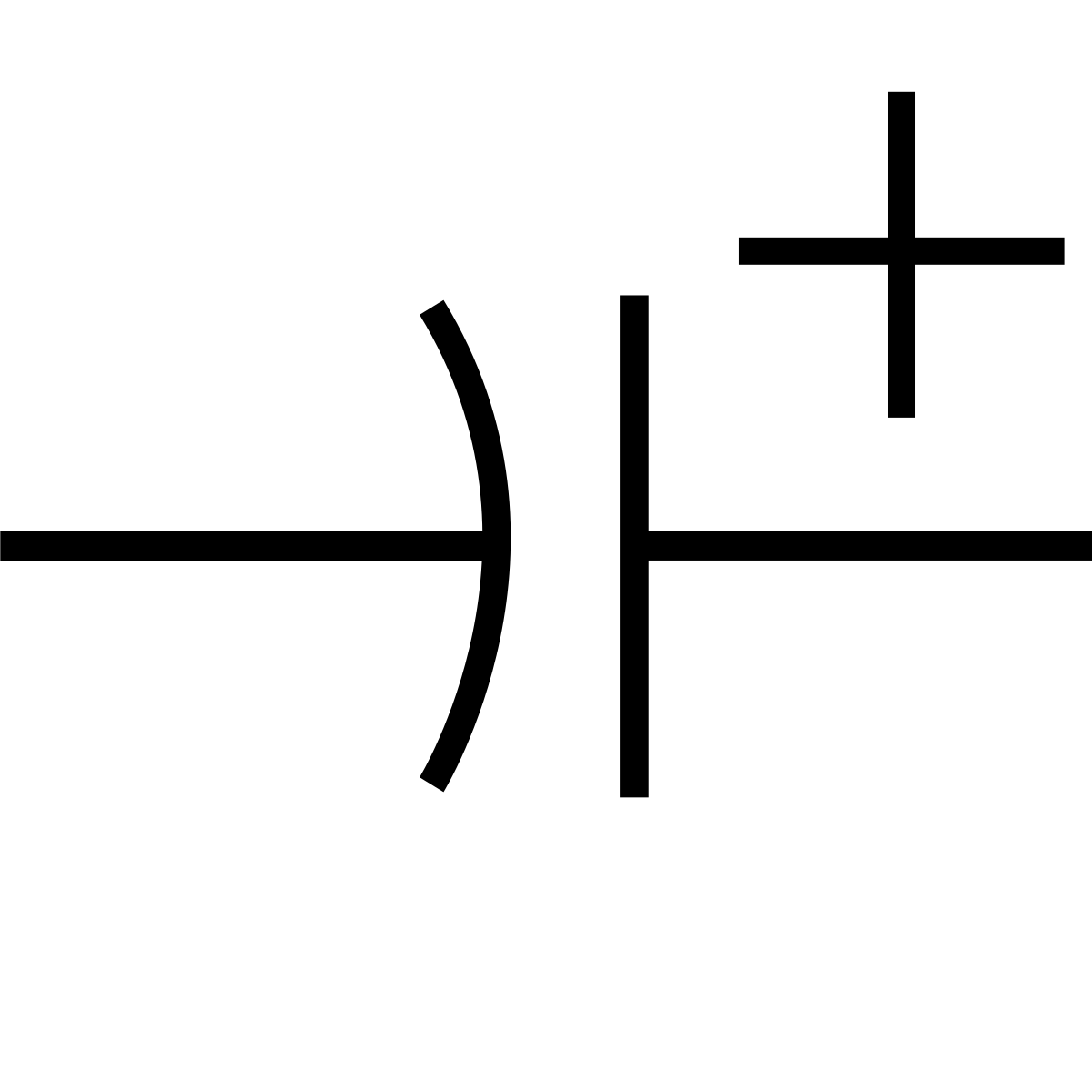

Tantalum electrolytic capacitors have tantalum electrodes. High capacitance density, stability, and dependability make these capacitors popular in electrical circuits.

Tantalum electrolytic capacitors are polarized and must be connected to the circuit correctly. They are used in audio, power supply, and other applications that demand high capacitance in a tiny size.

Niobium electrolytic capacitors have niobium oxide dielectrics. They are polarized like tantalum electrolytic capacitors therefore must be connected properly. Niobium electrolytic capacitors have high volumetric efficiency, enabling large capacitance in tiny packages.

Aluminum polymer capacitors employ conductive polymers instead of liquid or gel electrolytes. They are more stable, reliable, and resistant to temperature and aging. Aluminum polymer capacitors outlast electrolytic capacitors and offer better capacitance.

Tantalum polymer capacitors use conductive polymers instead of liquid or gel electrolytes. They are more stable, reliable, and resistant to temperature and aging. Tantalum polymer capacitors outlast tantalum electrolytic capacitors and offer higher capacitance..

Non-polarized electrolytic capacitors are non-polarized. In circuits with unknown polarity or reverse voltage, they can be connected in either direction.

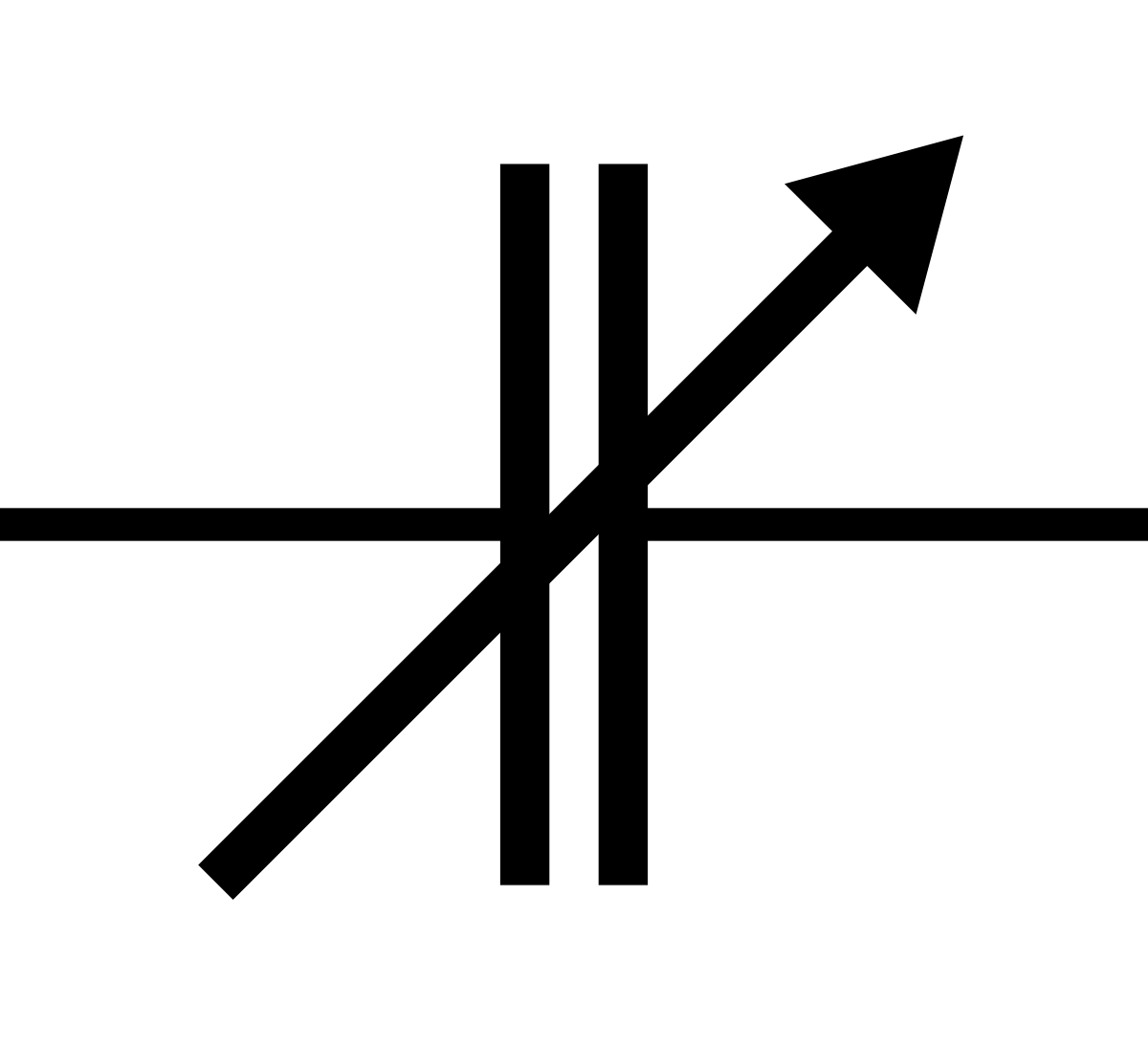

Electronic circuits use trimmers and variable capacitors to fine-tune frequency response. Circuit diagram symbols for these capacitors depend on their manufacture and features.

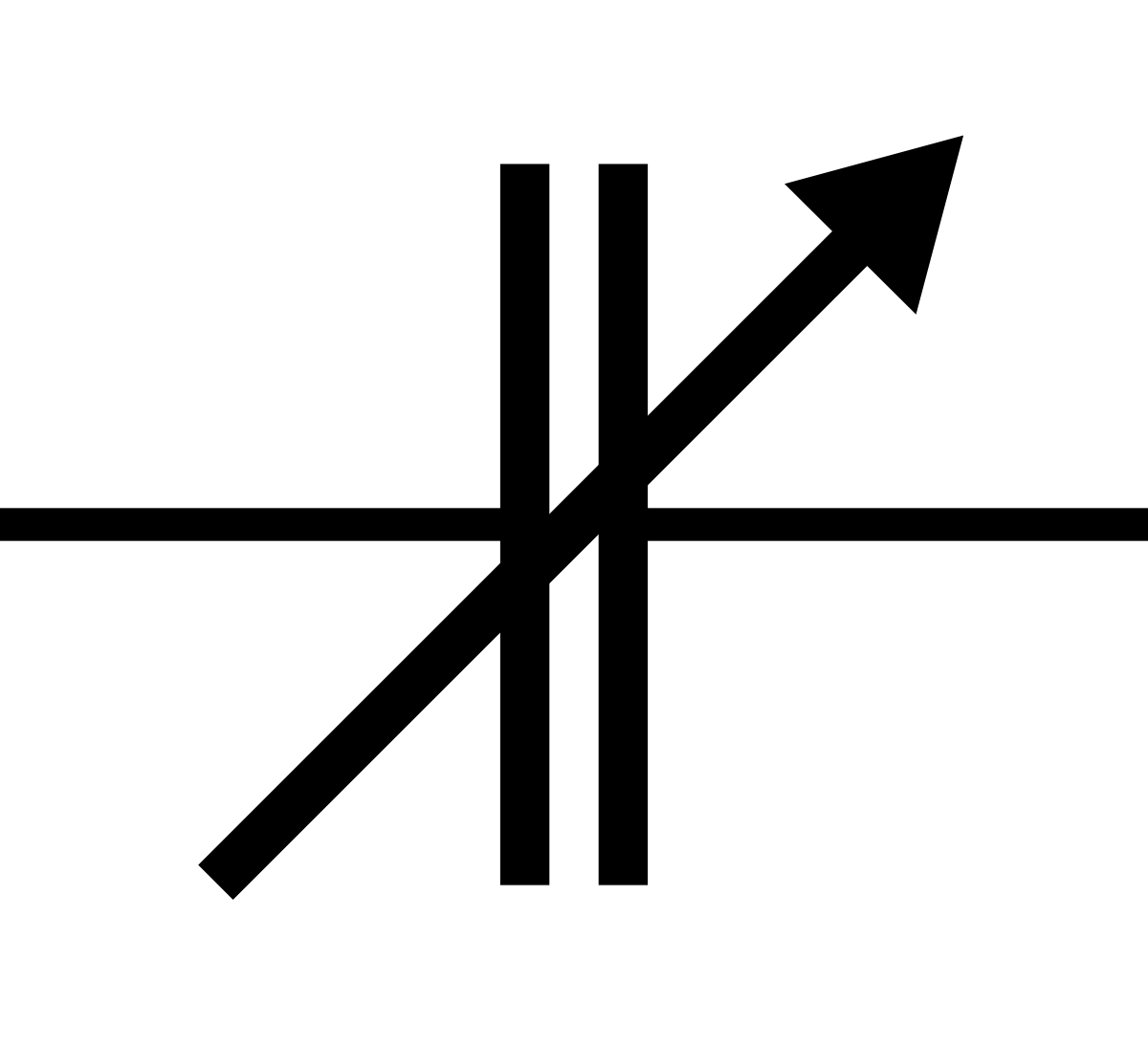

Variable capacitors are usually represented as a rectangle with two parallel lines and an arrow pointing toward the movable plate. One line represents the stationary plate and the other represents the mobile plate. The arrow shows that moving the plate changes the capacitance.

Air gap capacitors have two conducting plates separated by a small air gap. They are utilized in high-voltage and high-frequency applications where other capacitors may not work.

Air gap capacitors may survive high voltages due to their low dielectric constant. Low losses make them appropriate for high-frequency circuits. They have low capacitance and are larger than other capacitors.

Vacuum capacitors have two conducting plates separated by a vacuum. Due to their high voltage rating and capacitance density, these capacitors are suited for high-power RF circuits in transmitters, transceivers, and amplifiers.

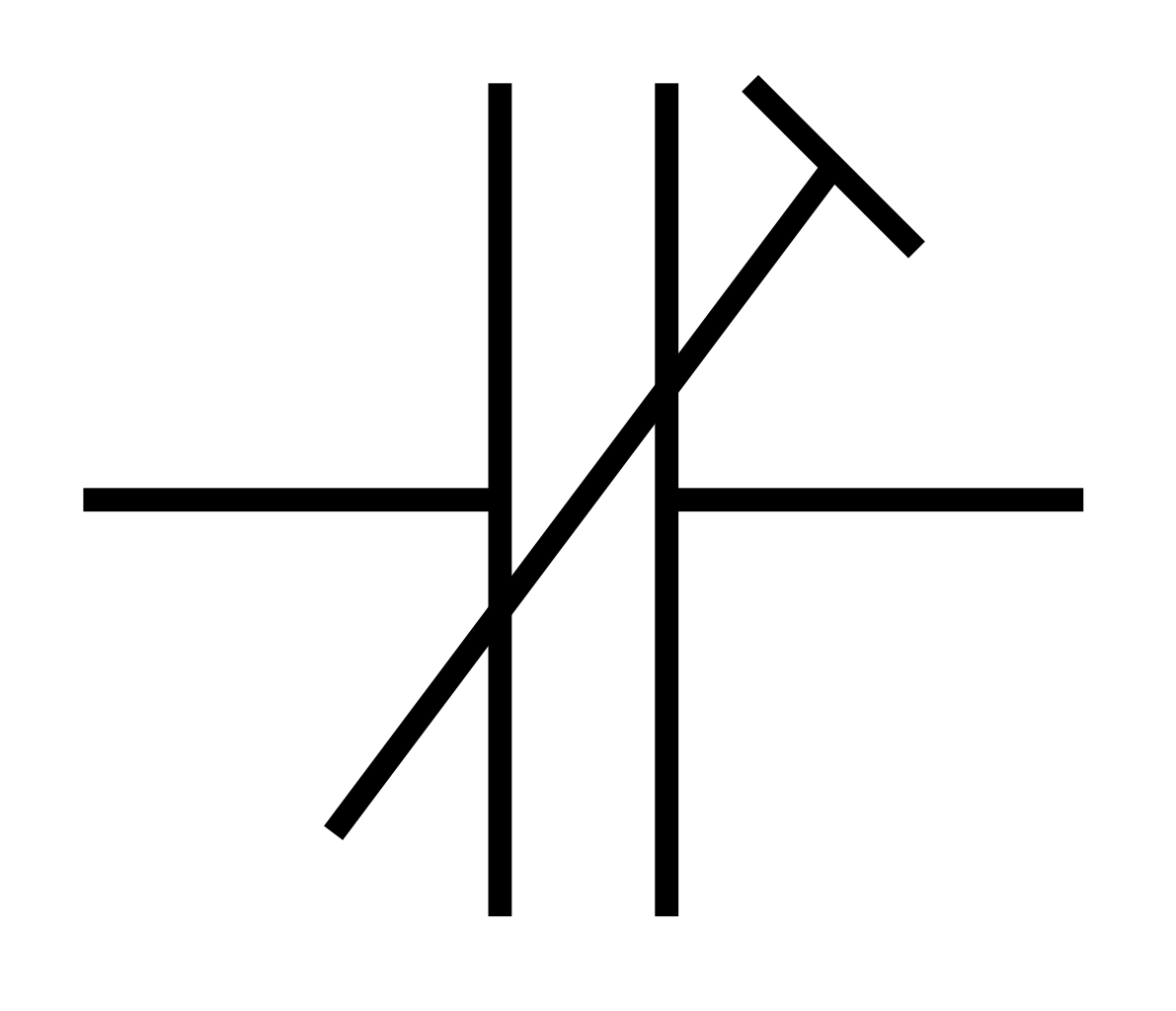

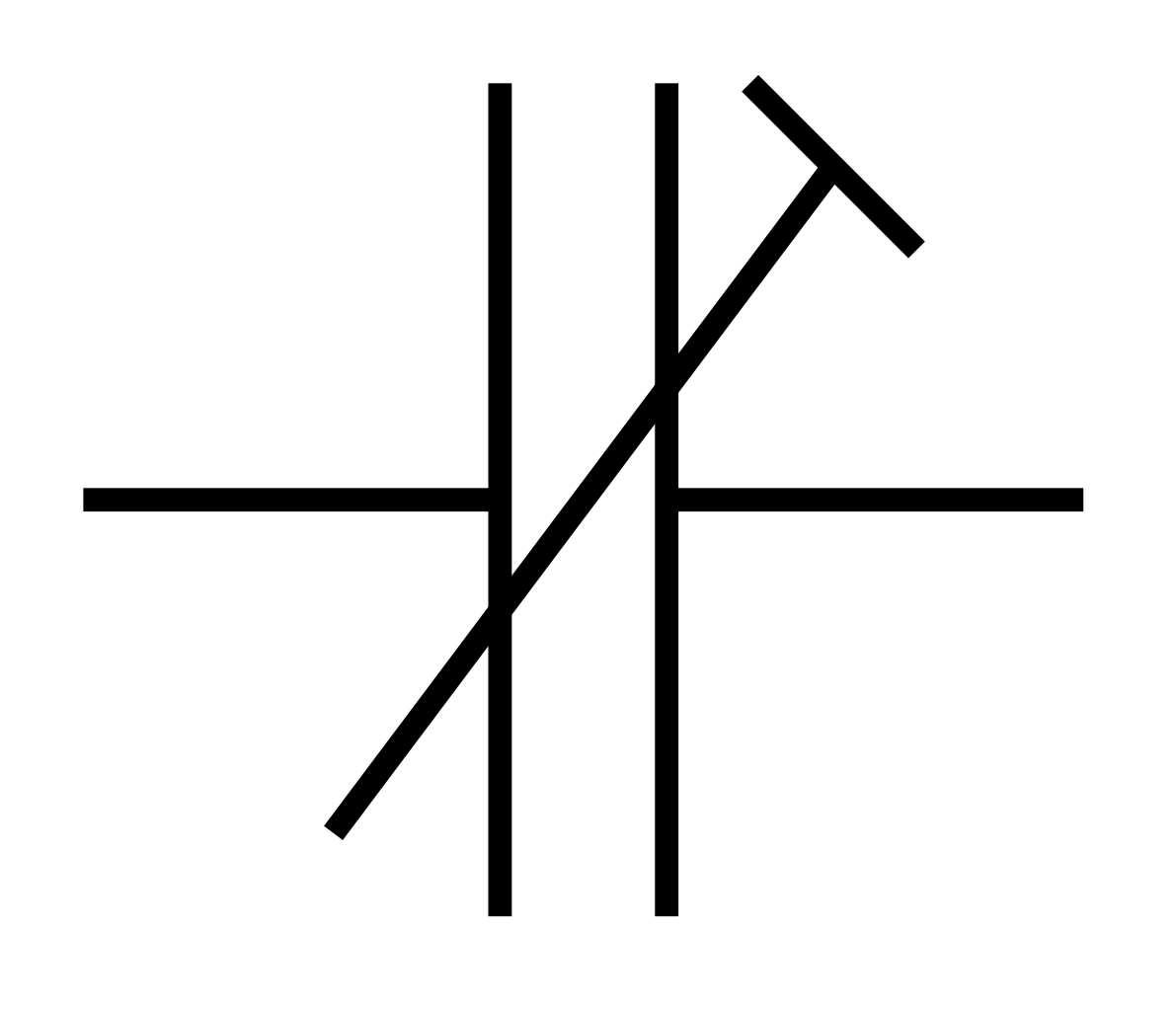

Electronic circuits can fine-tune capacitance with trimmer capacitors. RF circuits employ them for exact capacitance values. Trimmer capacitor symbols in circuit diagrams vary by construction and properties.

Trimmer capacitors are usually represented by a rectangle with a diagonal line through it, indicating that they are adjustable. The diagonal line is usually drawn at 45 degrees and varies in length depending on the trimmer capacitor configuration.

Ceramic trimmer capacitors fine-tune a circuit's capacitance. They have two conductive plates separated by a ceramic dielectric substance and one positioned on a movable arm to alter the capacitance value.

Radio receivers, transmitters, and oscillators use ceramic trimmer capacitors for accurate capacitance adjustments.

Film trimmer capacitors are another variable capacitor used to fine-tune circuit capacitance. They have two conductive plates separated by a thin film dielectric material and one positioned on a movable arm to alter the capacitance value.

Electronic circuits use various sorts of specialized capacitors, and their circuit diagram symbols rely on their manufacture and features. The symbol for specialized capacitors depends on the capacitor type and the circuit diagram designer or engineer's desire. To ensure proper circuit design and assembly, use the correct capacitor symbol for each kind.

Ultracapacitors, sometimes known as supercapacitors, store and release energy quickly. The capacitor's ability to store energy is shown in circuit diagrams by two parallel lines with a curved line connecting them.

Supercapacitors may have positive and negative signs to indicate polarity. Electric vehicles, renewable energy systems, and electronics use supercapacitors for high power and quick charge/discharge cycles.

Consider the circuit's capacitance, voltage rating, and other characteristics before choosing a supercapacitor. Preventing capacitor and circuit damage requires proper capacitor handling and installation.

Single-phase electric motor run and start capacitors boost torque and performance.

Performance and reliability depend on the motor run and start capacitor selection and installation. When choosing a capacitor for a motor application, consider the capacitance, voltage, and other characteristics.

Electronic circuits reduce EMI and noise with feedthrough capacitors. They block low-frequency transmissions and provide low-impedance paths for high-frequency signals.

Electronic circuit EMI suppression requires proper feedthrough capacitor selection and installation. When choosing a feedthrough capacitor, consider the application's capacitance, voltage rating, and other parameters.

Electroluminescent polymers (ELPs) in the active layers of light-emitting capacitors (LECs) emit light when an electric current passes through them. Due to their chemical and electrical structure, conjugated polymers can act as ionic conductors and semiconductors.

Tuning and RF circuits use silicon capacitors with reverse-biased p-n junction dielectrics.

Selecting and installing silicon capacitors correctly is essential for RF and tuning applications. When choosing a silicon capacitor for a circuit, consider the capacitance range, voltage rating, and other parameters.

Electronic circuits use the surface mount and leaded capacitors. Leaded capacitors feature leads for circuit connection, while surface mount capacitors are put directly on a circuit board.

Surface mount capacitors are rectangles with metal pads in circuit designs. The pads show where to solder the capacitor on the circuit board. Capacitance values can be printed on capacitors or indicated in circuit diagrams.

Consider the capacitor type and the circuit's needs before choosing a capacitor. Surface mount and leaded capacitors have pros and cons and may fit different applications.

Regional standards can alter capacitor symbols in circuit designs. Different locations and standards bodies use different capacitor symbols.

To simplify electronic component representation in circuit designs, capacitor symbols are standardized worldwide. However, capacitor symbols may vary by country.

In Europe, capacitors are depicted as curved lines or arcs, but in North America, they are parallel lines. Europe uses color-coded bands to show capacitor value more than North America.

China uses sharp, angular capacitor symbols, while Japan uses curved or rounder ones. The capacitor's performance is unaffected by these stylistic variances.

The International Electrotechnical Commission (IEC), IEEE, and ANSI ensure that electronic components and systems are safe, reliable, and interoperable worldwide.

The IEC creates and publishes international standards for electrical, electronic, and related technology worldwide. Its standards address electrical safety, electromagnetic compatibility, and electronic component and system performance.

IEEE promotes electricity, electronics, and computing technology. It creates standards for power systems, communications, and semiconductors.

ANSI represents U.S. standards and conformity assessment. It develops thousands of standards across numerous industries and collaborates with other international standards organizations to unify standards worldwide.

Electronics professionals and enthusiasts must understand capacitor symbols. Power supply, audio equipment, filters, and timing circuits require capacitors.

When designing or debugging electronic circuits, understanding capacitor symbols helps determine type, polarity, and capacitance. Choosing the wrong capacitor or connecting it incorrectly might cause circuit failure, component damage, or bodily injury.

Encouragement to further explore capacitors and their applications in electronics

Capacitors are fascinating electronics with many uses. Exploring capacitors' potential starts with learning their symbols and types.

If you like electronics, explore capacitors and their uses. Start by playing with different capacitors in simple circuits, reviewing their datasheets to learn about their electrical properties, and using them in more complicated circuits.

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now

|

Dimensions: (mm) |

|

|

Quantity: (pcs) |

|

|

Layers: 2 |

Thickness: 1.6 mm |

|

|

|