Support Team

Feedback:

support@nextpcb.comThere are numerous clinical tools in our everyday life as well as they are making use of a lot of medical PCBs. The manufacture and also style procedure of clinical PCB is the facility. The whole procedure is broken down right into various areas and also described thoroughly listed below.

The published motherboard (PCBs) made use of in the clinical market are really delicate as a result of their usage in conserving the lives of humans. The level of sensitivity of the clinical tools is worried about particular defined qualities that the clinical tools should have and also accuracy is one of the most vital qualities of all.

Clinical PCBs are specified as the published circuit card which is dedicatedly made for the structure of clinical tools as well as devices. They are committed to usage in a huge selection of treatment circumstances and also screening solutions. A couple of clinical gadgets, as well as equipment which are made up of a high proportion of PCBs, consist of glucometers, heart price screens, MRIs, CT-Scan, as well as X-Ray makers, and so on

The base of PCB is required to have numerous layers assisting in the decrease of degrees of SNR as well as sound. This is additionally leading to the improvement of the dependability and also the efficiency of PCBs.

For decrease of degrees of sound and also crosstalk in PCB under style, diversity of power and also ground airplanes is called for.

Costs of the product (BOM) is a checklist having information on all products and also parts needed in the PCB style. The testimonial of BOM is as a result a have to by both OEM and also PCB developers.

A robot gizmo is used for selecting the elements as well as putting them in a certain place on the board which is after that soldered. The element's placement is to be exact over soldering paste.

The second checklist of elements has to exist so regarding be utilized in case if a particular element stops working or does not meet the demand of layout. This checklist is important in conserving time throughout the layout procedure.

The recognition, as well as sign of all feasible examination factors in the PCB, are of important significance in order to decrease mistakes.

Various vital elements are required to be taken into consideration while making the PCB layout of the clinical sector such as split airplanes, sequencing, and also a variety of pins and also their choice.

The PCB Prototyping procedure is describing the treatment of sticking various parts and also products with each other onto a solitary board which is referred to as PCB. The procedure of setting up is the addition of elements with each other on the board in such a way that it learns to do a certain feature. Specific elements are required to be cared for while taking into consideration the setting up procedure of PCBs.

Application of a pattern is making a sure soldering paste to be put on every one of the components where parts are to be placed. The mechanical component is used for holding the PCB as well as a pattern onto a solitary location. Soldering paste is that used at designated locations via an applicator as well as is spread out. After elimination of the pattern, soldering paste is remaining from wanted areas.

The made PCB is most likely to execute based on demands under typical scenarios. Nonetheless, based on the criteria embedded in the clinical market a practical examination of PCB is performed to inspect its legitimacy. After the examination is performed as well as authorized, PCB is cleaned for the elimination of any type of change, dust, and also oil, and so on. This is additionally essential as a result of its application in the clinical market.

The board is conformed to a conveyor belt via the stove. Home heating is gone through at heats for melting soldering paste. The following action is cooling PCB for soldering paste solidification leading to the best joints amongst the board and also parts.

The parts need to be signed in order to understand whether these are satisfying the layout demands.

Producing an attraction for the procedure of setting up is a has to avoid any type of errors throughout construction. Keeping in mind of any type of required alterations is inescapable to handle modifications.

There is a need for different devices for the setting up procedure of PCB such as screening devices, assessment devices, SMT tools, and also soldering tools. Soldering cable, as well as paste, are additionally required needs. By the time all devices are obtained, the procedure of setting up can be begun. Nonetheless, as the clinical PCBs are much more delicate; for that reason, DFM examination transmission is a must. DFM examination is assisting in the correction of all feasible problems prior to the setting up procedure is launched. The complying with are the major actions of the setting up procedure of PCBs.

The very first step of the preliminary style of schematics is to obtain essential details concerning the application of emphasis as well as producing a standard illustration of its schematics. All information such as catching the sort of PCB, power need, as well as product to be utilized, and so on are integrated into the preliminary style.

The 2nd action is tinning the preliminary illustration as well as preparing a format via publishing the attraction to the software application. Now, the needs of customers are required to be contributed to the PCB.

The PCB is after that checked by hand as well as via makers by examiners for inspecting connection and also floorings which might cause malfunctioning. Various evaluation approaches are made use of such as optical examination, hands-on assessment, as well as x-ray examination.

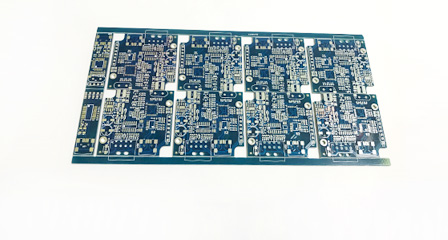

multilayer clinical PCBs are having greater than 2 layers of copper. Such PCBs might have 3, 4,5, ..., N layers. N signifies the variety of layers. The layers in multi-layered PCBs are demarcated via substratum boards in addition to insulation products. These PCBs are having the benefit of room, as well as thickness as well as, are used to make higher-speed circuits.

Double-sided clinical PCBs are having a certain metal conductive layer over among their substrate stages. Metal components can additionally be utilized from either of the sides via openings of the board. This is making it possible for links of dual-sided with the modern technology of openings. The leads of elements are put via the pierced openings on board as well as are after that soldered on contrary sides with pads.

The layout of medicines depends on the information of a particular populace. The clinical PCB modern technology has actually allowed the collection of information for far better as well as quicker growth of medications. Various gadgets have actually been made with clinical PCBs allowing quick as well as trustworthy structure of medications.

Countless clinical systems exist today which has actually made it extremely simple to share various details as well as notifies such as laboratory examinations. Such systems are utilizing mobile phones and also online applications. The benefit goes to its top as it passes info conveniently. Discovering neighboring health centers is really simple with such applications as well as is taken into consideration as a favorable adjustment from utilizing pagers and also PA systems. Such advancements have actually resulted as a result of clinical PCBs.

In the present period, many clinical wearables exist in order to check various info pertaining to the health and wellness of private specifical clients. For instance, football gamers are putting on various gizmos that check and also track their movement, heart and also pulse price, and so on. Such monitoring of various aspects is leading to real-time info on the wellness of a person.

The absence of digital documents was a significant issue prior to as well as it made use of to decrease the procedure of clinical solutions. A variety of individuals have actually passed away due to an absence of documents because of many factors. Nonetheless, with improvements in clinical PCBs, the record-keeping is enhanced as well as is reliable along with one-touch far from medical professionals.

Flex clinical PCBs are made up of adaptable products as well as can be of various sub-type such as solitary, dual, as well as multi-layered, and so on. Adaptability is making these PCBs the finest fit for area use. These PCBs are light in weight.

The model of clinical PCB has important significance since throughout the very early procedure of style screening of various capabilities of a detailed remedy is required to be carried out.

There are numerous sorts of clinical PCBs that are offered out there. Complying with are some significant usual kinds of clinical PCBs

Stiff clinical PCBs are constructed from a product that is not adaptable as well as for this reason their bases are not flexible. A variety of multi-faceted circuits can be developed from these PCBs as well as their conservation is additionally very easy when contrasted to various other sorts of PCBs.

For that reason, the model is being taken under a number of runs and also upgrading stages. Fewer times, a specific examination is considered inspecting a solitary capability, and also in some cases, extra examinations are carried out for inspecting the intricacy of style as well as its efficiency. The procedure of prototyping is aiding the developers in order to forecast the success as well as the failure of PCBs and also their resultant devices. The model is thus getting rid of losses that might happen as a result of issues being found. Prototyping is important in figuring out the accuracy of an element in the clinical field. The manufacturing of PCBs is just to be begun after developers and also designers are certain with servicing a model.

In current times smartphones, tablet computers, and also smartwatches have various applications as well as sensing units that precisely keep track of the wellness standing of the individuals. It has actually likewise improvisated using medicines and also the circulation of sharing details is facilitated. Applications on such gadgets have actually additionally made the very easy purchasing of medications. Documents of medications and also their study facets have actually likewise been boosted.

single-sided clinical PCBs are generally referred to as discriminatory PCBs as well as are made from single-layered substratum products. An extremely slim layer of detailed steel such as copper is made use of for layer one side of the substratum product. Such PCBs are having a solder mask that is used over the copper layer. Such PCBs prevail being used due to reduced expenses of manufacturing. In the clinical sector, such PCBs are utilized in circuits of power sensing units.

These PCBs are integrating the characteristics of both versatile and also stiff PCBs. These PCBs are requiring a specific variety of adaptable and also inflexible boards. Rigid-flex PCBs are chosen due to their lightweight and also restricted area use.

The clinical sector has actually seen a revolutionary boom in a current couple of years particularly due to PCBs. Additional study is required to be carried out for much better results as well as to resolve existing arising problems in the clinical sector. The transformation has actually just been feasible as a result of the development in modern technology. In present times, there are numerous sophisticated tools which are have actually brought the clinical sector transformation. The standard element of the transformation is PCB layout, construction, and also manufacturing.

The PCBs made use of in the clinical market are specially created based on needed requirements of the sector e.g., taking into consideration surface area plating, layer numbers, as well as openings, and so on. There are some significant applications of PCBs in the clinical sector out of which essential are stated listed below.

The clinical sector is amongst one of the most challenging as well as innovative markets worldwide. The sector has a greater degree of level of sensitivity as well as calls for accuracy in every choice. High technology-based tools are required to be integrated into the market to keep particular detailed criteria of the market. To provide excellent efficiency, the devices have to have digital devices having actually progressed circuits. This is the area where clinical PCBs are playing their function in keeping the top-notch capability of clinical tools.

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now

|

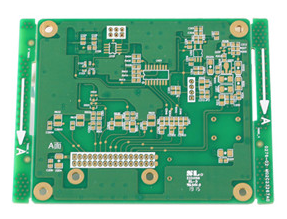

Dimensions: (mm) |

|

|

Quantity: (pcs) |

|

|

Layers: 2 |

Thickness: 1.6 mm |

|

|

|