Support Team

Feedback:

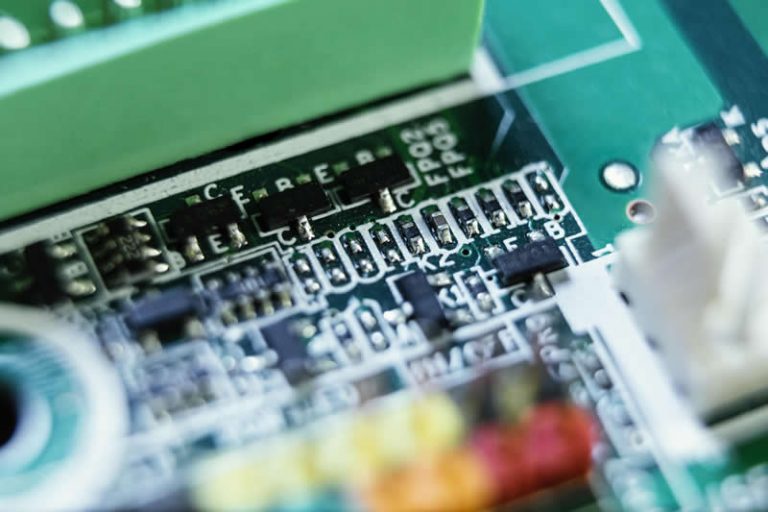

support@nextpcb.comIf you are in the Printed Circuit Boards (PCB) industry or a mere user of electronic products, then you know how important it is to test the boards after production, for release in the market. This is because the quality of the board determines how well they function in the field and how long they will last.

Functional Circuit Test (FCT) is a crucial part of the PCB assembly process and quality control of PCBs. It is vital for manufacturers to understand their responsibilities when conducting this testing. If you are one of those folks who want to know what the process involves and how it impacts the circuit boards, this article is for you.

In this article, we will provide a brief overview of what an FCT test is. We will cover how manufacturers carry out the test in the PCB manufacturing and assembly process, and how it can affect PCBs. By reading this article, you will gain a better understanding of the importance of the FCT Test in PCB production. Stick along with us and learn more!

FCT, or Functional Circuit Test, is a type of test used to check the functionality and integrity of printed circuit boards. Test operators usually carry out this test during the PCB production process, which is normally after the assembly process. Others sometimes refer to FCT as Function Verification Test (FVT) or Function Test. The FCT test helps to ensure that all elements are working as intended, properly connected, and produced to meet the requirements and standards in their entirety.

FCT covers testing the board by stimulating its input and output signals, like the voltage, current, and power, thereby assessing its components' response. Manufacturers typically use a dedicated FCT testbed with heavy-duty contacts to help ensure the PCBs function correctly. The higher currents of this method can introduce measurement inaccuracies due to excessive contact resistance, consequently providing a comprehensive view of the PCB's functionality.

This helps to identify any potential issues that could cause problems down the line before it enters the market for release to end users. Hence, it helps reduce time-to-market and costs that come with reworking or product recall. Additionally, FCT tests can help nail potential problems with components that may have gone unnoticed during the visual inspection process.

FCT testing provides a number of benefits for PCBs in the production process. It is a straight-up and accurate method of testing that can detect defects and ensure the quality of the product. FCT testing has the ability to identify and rule out the problems before they become costly or cause further and potential damage to the board. These include faults that the production process line may miss. Hence, it allows manufacturers to find and repair defects, thereby saving time and money quickly.

Furthermore, FCT testing helps manufacturers meet safety requirements, as they can identify any potential hazards in the product design. It provides an efficient means of verifying the proper placement of elements on the board, correct assembly, and that the product will function as expected. This process helps ensure that the PCBs are fully working and will perform their intended purpose.

FCT testing is an integral part of the printed circuit board production process. The functional circuit test is the last test in the PCB production process prior to delivery to the customer. The process ensures that all electrical connections work according to the PCB schematic. It checks all elements on the board, ensuring proper assembly of every part, and that all components are working.

During the FCT test, operators examine key elements and output waveforms through the relevant voltage or signal. They check every part to determine if the values meet certain parameters and standards.

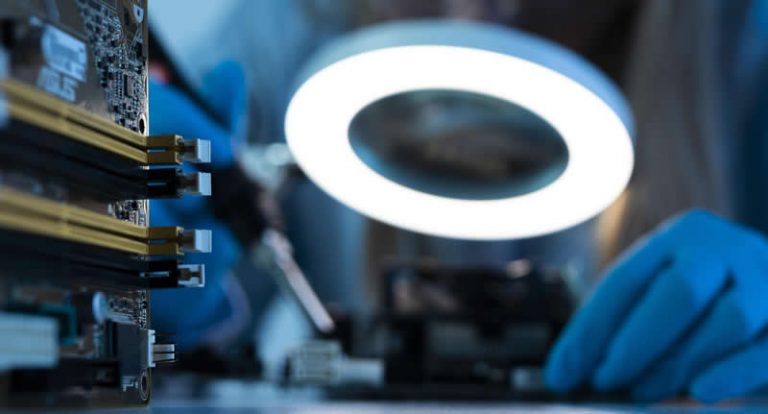

FCT testing usually follows after an Automated Optical Inspection (AOI). During this process, professional testers use equipment such as an oscilloscope or logic analyzer to detect any inconsistencies in the PCB design and structure. The focus of this test is to check any physical defects on the board. This allows for a more detailed analysis of the board's circuitry and can help identify issues that may not be visible to the naked eye.

During this visual inspection, the process helps identify potential defects such as wrong parts, broken connections, dry joints, faulty soldering, bridging, etc. To quickly identify the defects, a computer screen usually displays the test result, enabling testers to isolate any issues. Once this has been covered, and any deficiencies have been corrected, functional testing can then be done to ensure that all circuits are operating as expected.

The FCT test detects and rules out any problems with the circuits and other anomalies. Industrial FCT test usually requires the following items:

Planning which tests to run is usually the first step before beginning the FCT testing method. This may include listing the measures intended to employ when testing the board.

Functional testing involves connecting the electronic device to a test system and running a series of tests to ensure that all elements are working as they should. The electrical connection between different parts and their proper working condition is verified by applying power and signals to them and measuring their output response in terms of voltage and load. Depending on the complexity of the PCB design, operators perform different tests, including power-on tests, logic tests, and signal integrity tests.

Upon discovery of any issues during the test, skilled professionals isolate them and establish what causes the problem. All problems must be addressed before the device can be released for sale. If the board passes all tests, manufacturers clear it for further production operations and eventual release to the market.

The FCT test can help to ensure that any issues are caught quickly and resolved before they become major problems in actual use. It can also help prevent costly product recalls due to faulty parts or miswiring errors that occur during assembly. Therefore, conducting an accurate FCT test is essential to guarantee quality in PCB production operations.

The most effective PCB FCTs are often fully automatic or semi-automatic. Most functional testing methods have now become entirely automated as a result of the rapid development of technology and the need to increase production efficiency. The test software application, sometimes known as firmware by production line operators, facilitates the automation of functional testing.

To interface with the test application, operators usually employ an externally programmable instrument, such as an I/O board or digital multimeter. An FCT Test can be done using instruments attached to the device under test through a fixture and test application. On the other hand, manual and semi-automatic FCT are still popular to streamline design and lower production costs.

Manufacturers must ensure that their FCT testing is done according to industry standards and regulations. This includes ensuring that the test system is properly calibrated and maintained and that all elements are tested according to their specifications. Additionally, manufacturers must document all results from the tests and keep records of any changes or modifications made during the process.

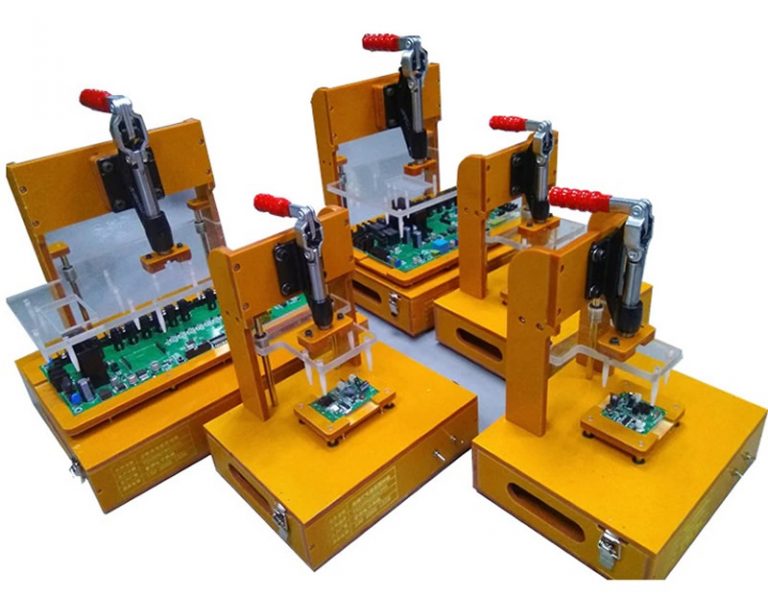

FCT test beds are designed to ensure that the PCBs are tested thoroughly and accurately. The test bed should be able to handle the product's multi-panel design, as well as accommodate pogo pins for probing. In addition, the bed should be designed so that it is able to provide a reliable connection between the probes and the PCB.

The design of the test bed should also address any potential risks of shorts or other problems that could arise due to the testing process. It should also take into consideration any elements that could be affected by Electromagnetic Interference (EMI) and take steps to mitigate this risk. Quick and easy access for maintenance and repair are also of equal importance, as it allows for efficient troubleshooting in case of problems.

All these considerations must be taken into account when designing an FCT test bed to ensure precise and straight-up results.

FCT tests can be challenging to perform due to their complexity and a large number of components and connections involved. Common challenges may include the need for precise control of temperature, accurate testing of components, and the difficulty in replicating complex connections.

The process can be time-consuming and expensive. Hence, it is important for manufacturers to understand how to maximize their resources when taking this type of testing. To save time and effort, some vendors perform functional testing on 50% to 100% of the product being supplied. The FCT test bed must be designed to ensure that all elements are tested accurately and reliably. In order to downplay errors, it is vital to select an FCT system that is reliable and easy to use. Ensuring that all components are tested properly during production is also important, as any errors in the test can lead to costly repairs or replacements down the line.

Investing in automated FCT systems may be considered to help streamline the process and reduce labor costs that come with manual testing operations. Some companies choose to outsource their FCT testing needs to a third-party provider who specializes in this type of testing. This helps reduce costs while still offering quality assurance for the device under test. There are a few factors to consider, though, when looking for an FCT test system.

Firstly, it is important to evaluate the performance of the system and ensure that it meets the design's requirements. Secondly, weigh the cost-effectiveness of the system, as well as its accuracy and reliability. The compatibility of the system with the existing equipment and operations is also equally important. Ultimately, it's vital to consider the safety functions coming with the system and ensure that it meets applicable regulations/standards.

Other electrical tests that examine for PCB production issues by assessing physical properties rather than functional responses, for example, detecting faulty soldering by assessing electrical resistances, are distinguished from functional testing.

FCT focuses on checking the electrical characteristics of a printed circuit board by stimulating it with different voltages and currents. In-Circuit tests (ICT), on the other hand, is a thorough, individual testing of each element on the board. It is commonly used to identify production defects such as open connections, solders, incorrect component placements, and incorrect component values.

These tests usually involve using a bed-of-nails test system. During this process, a PCB is tested by connecting it to multiple points through a series of spring contacts. The results of FCT testing are then compared to the design specifications to ensure that all elements are operating correctly.

FCT helps to identify and isolate defects in an assembled PCB, while ICT tests the overall functionality of the board. This combination of FCT and ICT tests allows PCB manufacturers to create boards with consistent quality and reliability.

While FCT testing ensures that a PCB meets design specifications and is free from production defects. It is important to note, however, that it may not guarantee that the product will 100% work when it reaches the end users due to a lot of factors. Therefore, proper design considerations should be taken into account when opting for an FCT test system for your PCBs.

NextPCB is a leading contract manufacturer of PCBs and provides quality and reliable testing services. With our extensive experience and advanced quality control system, we are able to provide comprehensive inspection, verification, and quality assurance for every PCB product.

Our team of field experts can quickly isolate any potential issues with the final product guaranteeing quality service and support. As a result, you can be sure that any product from NextPCB is of the highest quality and reliability. Ensuring that the final product meets our client's requirements is our top priority.

Functional Circuit Testing (FCT) is an important part of PCB production, conducted at the end of the line to test the board's performance in its intended environment. Testing involves hardware, and software (control unit, test adapters, test applications, and sensors) to detect defects, vulnerabilities, and potential failures. Tests range from simple visual inspections to complex in-circuit tests to check electrical inputs, user interface operations, and environmental conditions. Vendors may combine FCT with In-Circuit Testing for higher accuracy. FCT identifies faults such as incorrect component values, functional issues, and parametric issues. Choosing the right test system is essential to ensure quality results, and save time and money. It's also important to understand your responsibilities when conducting FCT. Our team can help with your printed circuit board assemblies and provide professional services if needed.

Related Blog

FREE Functional Testing for your Prototype PCBA with HQ NextPCB

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now

|

Dimensions: (mm) |

|

|

Quantity: (pcs) |

|

|

Layers: 2 |

Thickness: 1.6 mm |

|

|

|