Support Team

Feedback:

support@nextpcb.comWith the rising need for miniaturization and also high assimilation of digital items, increasingly more PCB design creates a take on blind as well as buried vias modern technology to boost circuit thickness of PCB boards. PCBs with blind and/or buried vias have even more area for electrical wiring than typical PCBs. As well as blind well as buried vias are extensively utilized in multilayer published motherboard production.

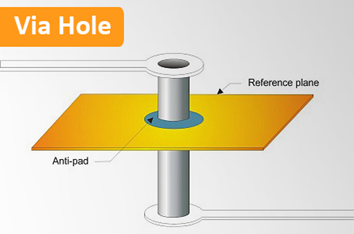

A Via Hole in a PCB is a copper through-plated Hole, which includes 2 pads in matching placements on various layers of the circuit card, that are electrically attached by a Hole via the board. The hole is made conductive by electroplating.

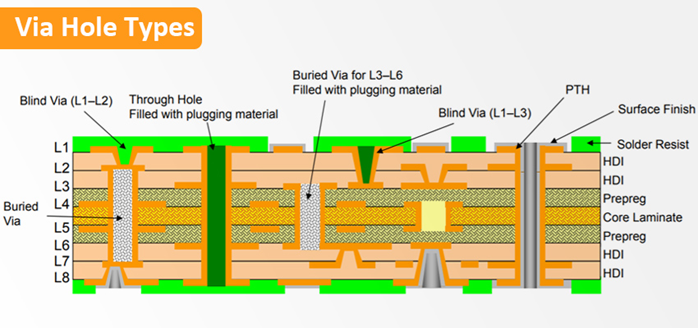

Via-hole Types

Attaches an external layer to several internal layers however does not undergo the whole board, and also they show up from the one external layer yet not noticeable from the various other external layers.

Links 2 or even more internal layers however do not experience an external layer, and also they are not noticeable from any kind of among the external layers.

Blind Vias and also buried vias are utilized to link in between layers of a published circuit card where room goes to a cost. Yet not all mixes are feasible. It is defined by UL (Underwriters Laboratories) that 3 thermal press cycles are optimum. Hence, for optimum integrity and also high quality we can not generate multi-layer PCB boards that call for greater than 3 lamination actions. What this suggests is you might bot style vias as if it would certainly take greater than 3 actions to construct them. Besides, blind as well as buried vias include substantially to the price of a circuit card. They need to just be made use of when definitely needed. To aid PCB developers of limited published boards, we provide using Holes to 0.2 mm, and also microtia to 0.1 mm( 4mil). These require minimal external layer pad dimensions of 0.45 mm and also 0.4 mm specifically.

Blind and also buried Vias Production Capabilities

We make use of a mix of depth-controlled laser exploration as well as mechanical NC exploration to make the blind and/or buried vias. The blind as well as buried vias making abilities for conventional PCBs as well as HDI PCBs as adhering to.

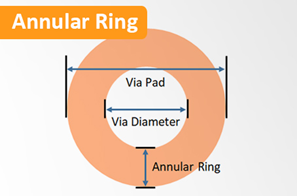

| Via Type | Via Diameter (max) |

Via Diameter (min) |

Via Pad | Annular Ring | Aspect Ratio |

|---|---|---|---|---|---|

| Blind via (mechanical) | 0.4mm | 150µm | 450µm | 127µm | 1:1 |

| Blind via (laser) | 0.1mm | 100µm | 254µm | 150µm | 1:1 |

| Buried via (mechanical) | 0.4mm | 100µm | 300µm | 150µm | 1:10 |

| Buried via (laser) | 0.4mm | 100µm | 225µm | 150µm | 1:12 |

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now

|

Dimensions: (mm) |

|

|

Quantity: (pcs) |

|

|

Layers: 2 |

Thickness: 1.6 mm |

|

|

|