Support Team

Feedback:

support@nextpcb.comBOM stands for the bill of material. A BOM is a list of materials used in PCB manufacturing and assembling. The function of a BOM is to provide the engineer with all he needs to produce a circuit board. In most random cases, the bill of material is the first thing in PCB manufacturing that gets finalised and proceeded.

As stated above, a Bill of material has all the necessary information, such as the size, manufacturer and packaging type. It is efficient to do it at first as later it helps the PCB designer to design the footprints of components and also helps to check whether the required element is available in the market in the desired packaging, size and manufacture.

PCB assembly is a process of soldering components at their designated places. During the assembly process, a BOM serves as a unified reference that enlists in-depth and necessary information about all the materials and components used in the circuit board.

Having an appropriately created and filled bill of material in hand aids the PCB assembler in many ways, such as

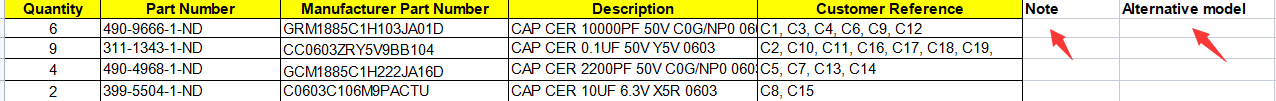

There are some must-have fields that should be in every BOM because each column thoroughly defines the characteristics of the component.

It gives the exact number of individual components used in the circuit and helps keeping the track of rows.

To make the shopping process for components easy and budget-friendly, a comprehensive BOM should have mentioned the quantity of the parts required per board. On the safe side, if a person or an organization decides to assemble their PCB, they should always order some extra components than their requirement.

The description is a recommended field by many Research and Development folks. It is the field where designers put all the additional but essential information about the parts.

A manufacturer usually assigns an individual part number to each component to minimize the chances of misunderstanding and preserving their royalty. Hence the primary purpose of an MPN that makes it a significant field in the BOM is to ease part identification.

Some circuit boards may serve multiple applications in different modules with a change in particular components. Hence there are many components that a designer/engineer avoids assembling permanently. These components may include power supplies, capacitors, connectors etc. Dedicating a specific field to describe the installation status is essential to highlight the do not populate/do not install (DNP/DNI) components.

A reference number/designator helps avoid the miss-assembling of a component. Each component on the circuit board has a unique reference designator such as Resistors may have reference designators such as R1, R2, R3 and so on. These individually unique reference designators are already silk-screened on the PCBs. Hence, adding this field to the BOM is significant.

The vendor name field is optional. But adding this field in your BOM helps cutting-off the hustle of finding a component online or offline.

The vendor usually assigns each component an individual part number to find a particular piece rapidly. Adding a field of vendor part number may help reduce the time taken to find each component in the BOM. However, this is an optional field.

Electrical values of the components.

The size of the component should be a mandatory field in the BOM as it describes the space a particular piece will take on the circuit board.

Again the component's manufacturer's name is an optional field, but it helps to get the original component.

The package type of a component describes its packaging. It denotes whether the component packaging comprises 3-legs, 4-legs, and other similar characteristics.

An alternate part number helps select another component if in case the original part is not available.

The easiest way to mark an alternative part number in a BOM is to simply put it beside the manufacturer part number and highlight it with a different colour to make it prominent.

A BOM is a list mentioning all the materials required to produce a PCB. Thus it helps estimate the cost in terms of several factors, such as if all the components are locally available or not, helps compare the prices of the parts and materials from the different vendors etc. However, if designers use modern software to create BOM, it can make their lives easier. Because BOM software usually provides automatic price comparison and automatically updates the prices if they fluctuate.

The NextPCB recommends a BOM that has as many details of the parts mentioned as possible to ensure an error-free buying and assembling of the components. To aid your learning NextPCB is incorporating an example of a Bill Of Material BOM.

As we know, a BOM has several optional and mandatory fields to describe a component. We can make a BOM using a spreadsheet (Microsoft Excel or Google Sheets). Excel is an easy and affordable option for BOM if you do not want to spend on a particular BOM software. The only drawback of using excel or google sheets is that they are time-consuming. However, the updated BOM software provides more advanced and time-saving features, such as updating the part availability status and easy format change.

Here you can download a free Excel BOM template by NextPCB.

NextPCB has been providing PCB manufacturing, testing, assembling and component sourcing for more than 15 years. We at NextPCB manufacture FR-4, metal (e.g. aluminium), ceramic-based, LED and high-frequency PCBs and proudly source high-quality components for our worldwide clients. For NextPCB, quality and the client's satisfaction are the priority. Hence we always test our components before shipping them to you or assembling them on the circuit boards.

To experience outclass customer care and quality, contact us to get a PCBA quote on your BOM from your exclusive salesperson.

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now

|

Dimensions: (mm) |

|

|

Quantity: (pcs) |

|

|

Layers: 2 |

Thickness: 1.6 mm |

|

|

|