Support Team

Feedback:

support@nextpcb.comWhat is SMD Adhesive

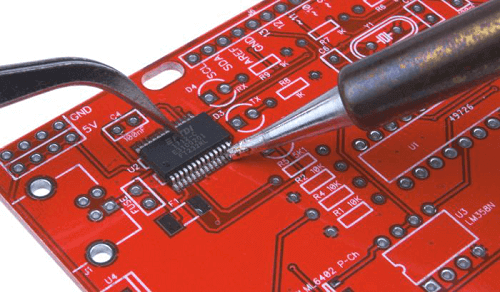

SMD Adhesive is likewise called Surface area Mount Adhesive. Before soldering, elements with pin get in touches with or SMDs are usually bound to the PCB with sticky. This enables, for instance, numerous capacitors, electrolytic capacitors as well as coils to be placed on a motherboard and also treated within simply a couple of secs to avoid their tipping over or sliding out of setting on the PCB. The protected parts can after that be reflow-soldered in a solitary job action, which conserves time as well as accelerates manufacturing.

The SMD sticky describes the adhesives of setting representatives, pigments, as well as a solvent button, which are equally dispersed at a loss paste, which is primarily utilized to repair the part on the published board, and also typically it is designated by the approach of factor coated.

SMD Adhesive Features

SMD adhesive must have the complying with Features.

( 1) The numerous of install innovations

( 2) It is very easy to establish the supply quantity of each element.

( 3) Easy adjustment substitute components selections.

( 4) The quantity of giving is secure.

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now

|

Dimensions: (mm) |

|

|

Quantity: (pcs) |

|

|

Layers: |

Thickness: |

|

|

|