Support Team

Feedback:

support@nextpcb.com

The middle layer is the layer between the top and bottom layers of the PCB. Refer to Figure 1 for its structure. Readers can refer to the annotations in the figure for understanding. How is the middle layer realized in the production process of PCB? Simply put, multi-layer boards are made by pressing multiple single-layer boards and double-layer boards, and the middle layer is the top or bottom layer of the original single-layer boards and double-layer boards.

In the production process of the PCB board, it is first necessary to apply a copper film on both sides of a base material (usually a synthetic resin material), and then convert the wire connection relationship in the drawing to the board of the printed board through a process such as light painting ( Protect the printed wires, pads and via coatings in the drawings to prevent these parts of the copper film from being corroded in the next corrosion process), and then through chemical corrosion (with FeCl3 or H2O2 as the main component) Corrosion solution) will corrode the copper film without film protection, and finally complete the post-processing work such as drilling and printing the silk screen layer, so that a PCB board is basically completed.

In the same way, a multi-layer PCB board is pressed into a circuit board by a pressing process after multiple layers are completed, and in order to reduce cost and via interference, a multi-layer PCB board is often no better than a double-layer board and a single-layer board. How much thicker, which makes the layers of the multi-layer PCB compared to ordinary double-layer boards and single-layer boards tend to be smaller in thickness and lower in mechanical strength, leading to higher processing requirements. As a result, the production cost of PCB boards is much more expensive than ordinary boards and single-layer boards.

However, due to the existence of the intermediate layer, the wiring of the multilayer board becomes easier, which is also the main purpose of selecting the multilayer board. However, in practical applications, multi-layer PCB boards put forward higher requirements for manual wiring, which makes designers need more help from EDA software; at the same time, the existence of intermediate layers allows power and signals to be transmitted in different board layers. , The signal isolation and anti-interference performance will be better, and the large-area copper connection power and ground network can effectively reduce the line impedance and reduce the ground potential deviation caused by the common ground. Therefore, PCB boards with a multilayer board structure usually have better anti-interference performance than ordinary double-layer boards and single-layer boards.

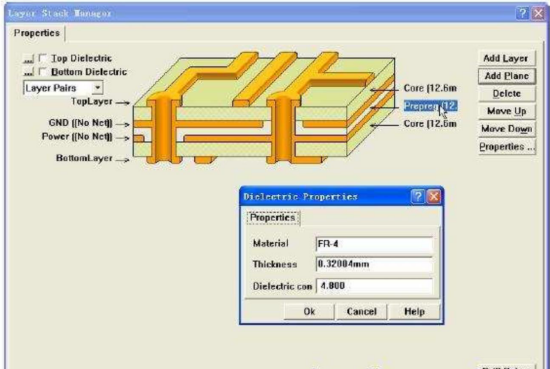

The Protel system provides a special layer setting and management tool—Layer Stack Manager. This tool can help designers add, modify and delete working layers, as well as define and modify layer attributes. Select the [Design]/[Layer Stack Manager...] command, and the layer stack manager property setting dialog box shown in Figure 2 will pop up.

The above figure shows the layer stack manager interface of a 4-layer PCB board. In addition to the top and bottom layers, there are two internal power layers (Power) and ground layers (GND). The locations of these layers are clearly shown in the figure. Double-click the name of the layer or click the Properties button to pop up the layer properties setting dialog box, as shown in Figure 3. In this dialog box, there are 3 options that can be set.

There are 3 options that can be set in this dialog box.

(1) Name: Used to specify the name of the layer.

(2) Copper thickness: Specify the copper film thickness of this layer, the default value is 1.4mil. The thicker the copper film, the greater the current carrying capacity of the line.

(3) Net name: Specify the network connected to this layer in the drop-down list.

This option can only be used to set the internal electrical layer, the signal layer does not have this option. If the internal electrical layer has only one network such as "+5V", then you can specify the network name here; but if the internal electrical layer needs to be divided into several different areas, then do not specify the network name here.

There are insulating materials between the layers as the carrier of the circuit board or for electrical isolation. Among them, Core and Prepreg are both insulating materials, but Core is a sheet with copper films and wires on both sides of the board, while Prepreg is only an insulating material used for interlayer isolation. The property setting dialog box of the two is the same. Double-click Core or Prepreg, or select the insulation material and click the Properties button to pop up the insulation layer property setting dialog box. As shown in Figure 4. The thickness of the insulating layer is related to factors such as interlayer withstand voltage and signal coupling. It has been introduced in the previous layer selection and stacking principles. If there is no special requirement, the default value is generally selected.

In addition to the two insulating layers "Core" and "Prepreg", there are usually insulating layers on the top and bottom layers of the circuit board. Click on the figure 2, the choice before Top Dielectric (top insulation layer) or Bottom Dielectric (bottom insulation layer) in the upper left corner to select whether to display the insulation layer in the box, and click the button next to it to set the properties of the insulation layer.

There is a stacking mode selection drop-down list under the options of the top and bottom insulation layer settings, and different stacking modes can be selected: Layer Pairs, Internal Layer Pairs and Build up . As mentioned earlier, the multilayer board is actually made by pressing multiple double-layer boards or single-layer boards. Choosing different modes means that the actual

Different pressing methods are used in the actual production, so the positions of "Core" and "Prepreg" as shown in Figure 5 are also different. For example, the layer pair mode is two double-layer boards sandwiching an insulating layer (Prepreg), and the inner electric layer pairing mode is two single-layer boards sandwiching a double-layer board. The default Layer Pairs mode is usually used.

After completing the relevant settings of the layer stack manager, click the OK button to exit the layer stack manager, and you can perform related operations in the PCB editing interface. When operating the middle layer, you need to first set whether the middle layer is displayed in the PCB editing interface. Select [Design]/[Options...] command, as shown in Figure 6.

Tick the option of the internal electrical layer under Internal planes to display the internal electrical layer. After completing the settings, you can see the displayed layers under the PCB editing environment. Click the layer label of the circuit board with the mouse to switch between different layers for operation. If you are not used to the default colors of the system, you can choose the Colors option under the [Tools]/[Preferences...] command to customize the colors of each layer for readers' reference.

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now

|

Dimensions: (mm) |

|

|

Quantity: (pcs) |

|

|

Layers: |

Thickness: |

|

|

|