Support Team

Feedback:

support@nextpcb.com

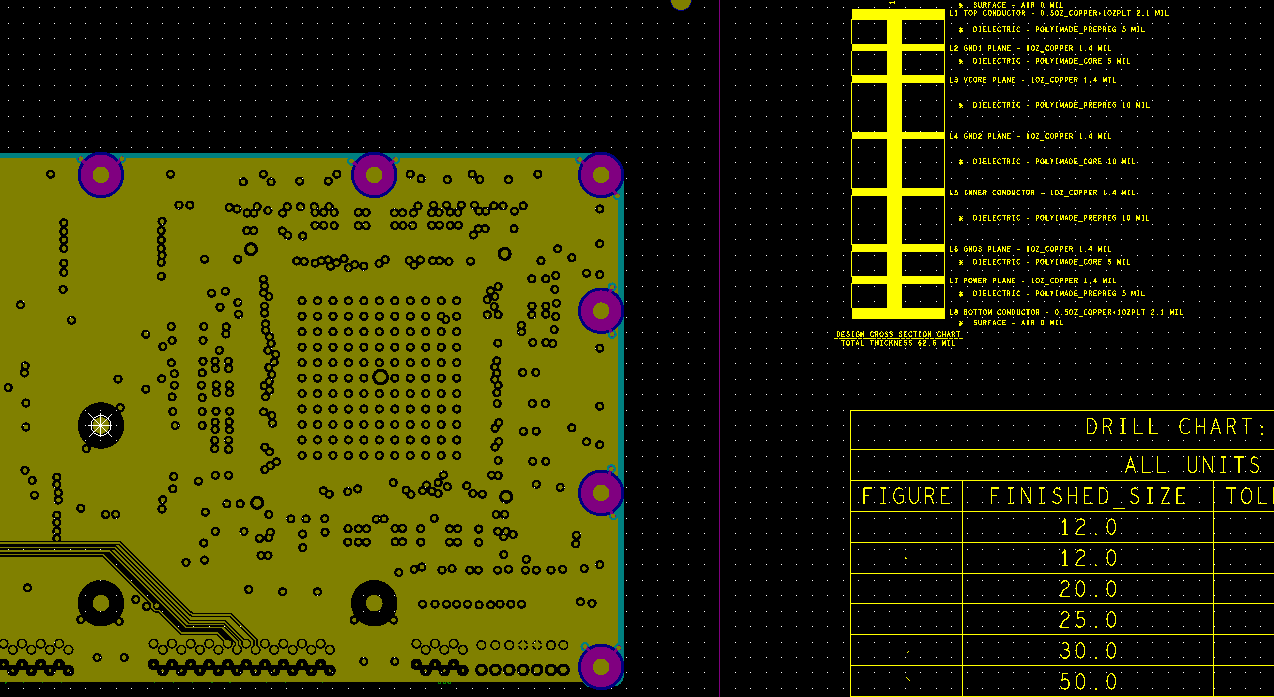

When working on a complex PCB layout, designers tend to rely on the DRC engine in their CAD software to spot errors that can reduce manufacturing yield. Some electrically correct design choices will create DFM problems that need to be found and fixed before sending a PCB out for manufacturing. PCB designers normally do these checks in their PCB layout file before it’s exported to Gerber files, but the Gerber files should always be reviewed before a board is sent into manufacturing.

The list of design and DFM problems below is not an exhaustive list, but these are some areas that any designer should check before sending their Gerber files to a manufacturer. There are 6 common DFM problems that can be found in many PCB designs:

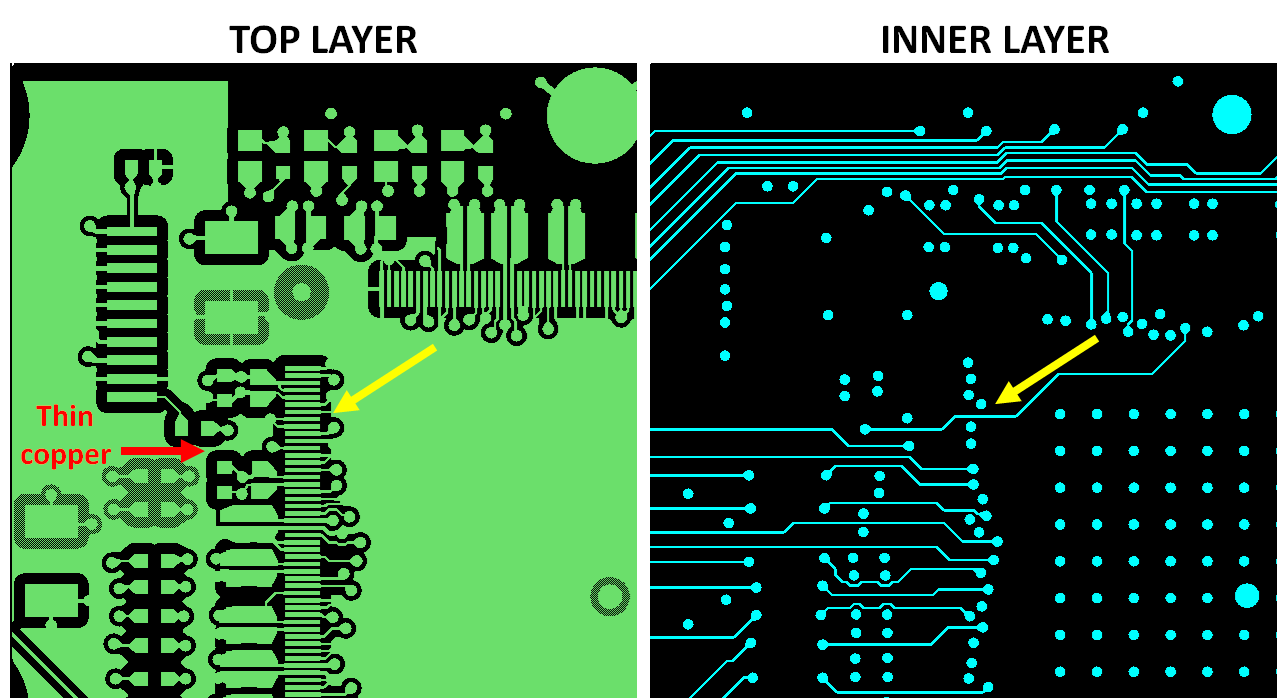

Thin copper can be identified in the top layer, and there may be a clearance problem between traces and vias on the inner layer.

It’s important to note that these design problems might not trigger an electrical DRC error unless you’ve specifically created design rules for these points in your PCB design software. Therefore, designers need to check their Gerber files for these DFM problems either manually or with automated Gerber file checker software.

Designers need to review these potential problems before starting their fab run, but not all designers have access to the same Gerber file checker software as professional manufacturers. This means designers have to rely on the DRC engine in their CAD tools, or they have to manually look through the Gerber files to make sure they exported correctly. Here are some problems with doing a manual Gerber file check:

With so many potential problems to be inspected before fabrication, PCB designers need an automated solution to help them quickly get through

The fastest way to spot manufacturability problems in your Gerber files is to use Gerber file checker software. Most of these applications will only accept Gerber files in RS-274X and X2 formats, although other applications are available that support IPC 2158, ODB++, or native CAD files. Any PCB designer can find these tools useful as they can support multiple fabrication file formats and CAD formats.

All Gerber file checker applications are designed to spot any problems in your PCB layout that will reduce fabrication or assembly yield. Most of these applications are used for viewing, editing, and quickly inspecting some basic DFM requirements in a PCB layout. However, the best Gerber checking programs provide other important benefits:

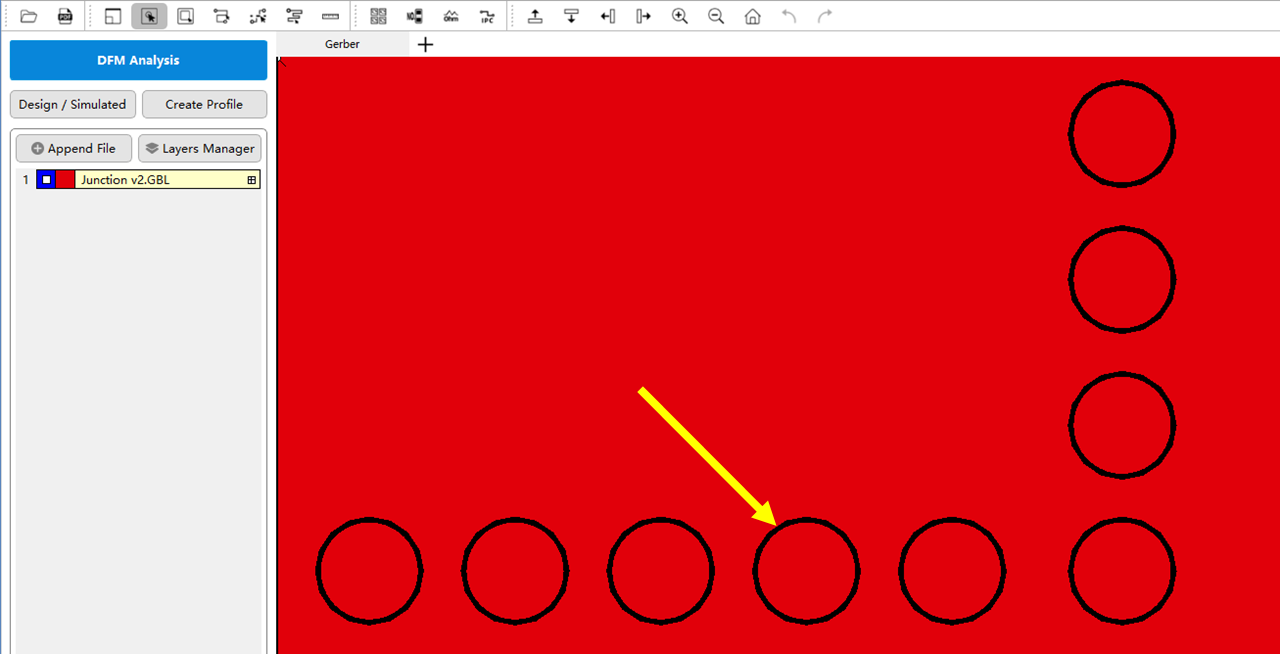

CAD tools often apply 1 mil clearances by mistake when grounding a net to a plane or polygon. These vias are supposed to be connected to the surrounding plane, and this clearance mistake can be found with an automated Gerber file checker.

With these capabilities, a designer can quickly identify design problems before the PCB gets sent in for fabrication and assembly. Unless you pay for a turnkey service or enhanced inspection level, the fabricator might not inform you of these problems, leading to a failed fabrication run. You can take the risk out of manufacturing with the best PCB design review software.

No download, no sign-up, no obligation.

HQDFM Gerber Viewer is a free, advanced PCB Gerber file and OBD++ file visualizer with in-depth Design for Manufacture (DFM) analysis capabilities. It supports RS-274x and Extended (X2) Gerber files from a broad range of PCB CAD software, including but not limited to Altium Designer, OrCad/Allegro, Eagle, KiCad, DipTrace, DesignSpark, and EasyEDA, and works with the top 5 web browsers. Developed by HQ Electronics, HQDFM Gerber Viewer leverages over 15 years of expertise from the industry's experts to provide advanced manufacturing insights.

Once you’ve checked your PCB layout in HQDFM, you can quickly put the design into fabrication with NextPCB, one of China’s most experienced and reliable PCB manufacturers. You’ll know that the pricing analysis you see in HQDFM is accurate and your design will pass NextPCB’s quote and review process.

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now